Keyestudio 2021 Complete Starter Learning Kit

Introduction

Do you want to learn about programming?

As long as you are passionate about science and dare to explore new things, this kit is surely the best choice for you.

The kit is used to Arduino-based Scratch graphical programming and C language.

You can create numerous fascinating experiments with the PLUS mainboard,sensors,modules and electronic components.

As many as 32 project tutorials are provided, which contain detailed wiring diagrams, component knowledge, test code, and so on.

In addition, you can master the use of electronics, physics, science and programming by building up experiment with this kit.

Kit List

(KS0538 includes Plus mainboard, KS0539 does not include Plus mainboard.)

|

|

|

|

|

|---|---|---|---|---|

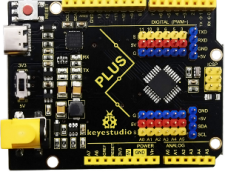

Plus Mainboardx1 |

Blue LEDx10 |

Red LEDx10 |

Yellow LEDx10 |

Green LEDx10 |

|

|

|

|

|

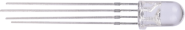

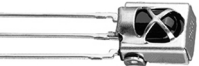

RGBx1 |

220Ω Resistorx10 |

10KΩ Resistorx10 |

1KΩ Resistorx10 |

4.7KΩ Resistorx10 |

|

|

|

|

|

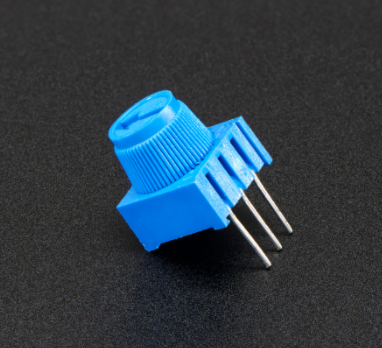

10KΩ Potentiometerx1 |

Active Buzzerx1 |

Passive Buzzerx1 |

Buttonx4 |

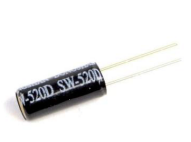

Tilt Switchx1 |

|

|

|

|

|

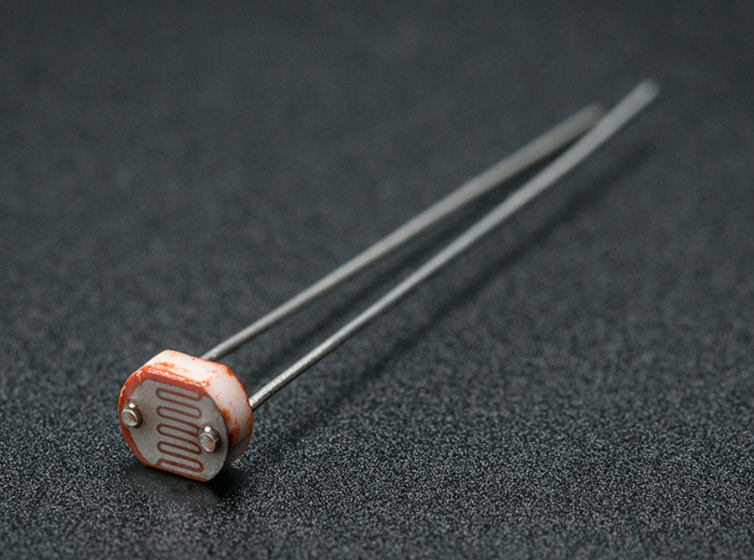

Photoresistorx2 |

Flame Sensorx1 |

10KΩ thermistorx1 |

Yellow Capx4 |

IC 74HC595N x1 |

|

|

|

|

|

Joystick Modulex1 |

1-Digit Tube Displayx1 |

4-Digit Tube Displayx1 |

8x8 Dot Matrix Display x1 |

IC L293Dx1 |

|

|

|

|

|

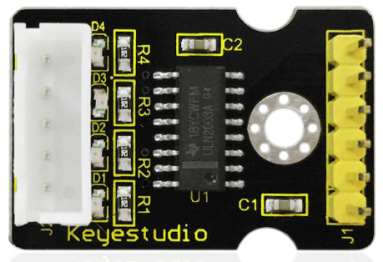

LCD_128X32_DOT x1 |

IR Receiverx1 |

ESP8266WIFI ESP-01x1 |

PIR Motion Sensorx1 |

Fanx1 |

|

|

|

|

|

DC Motorx1 |

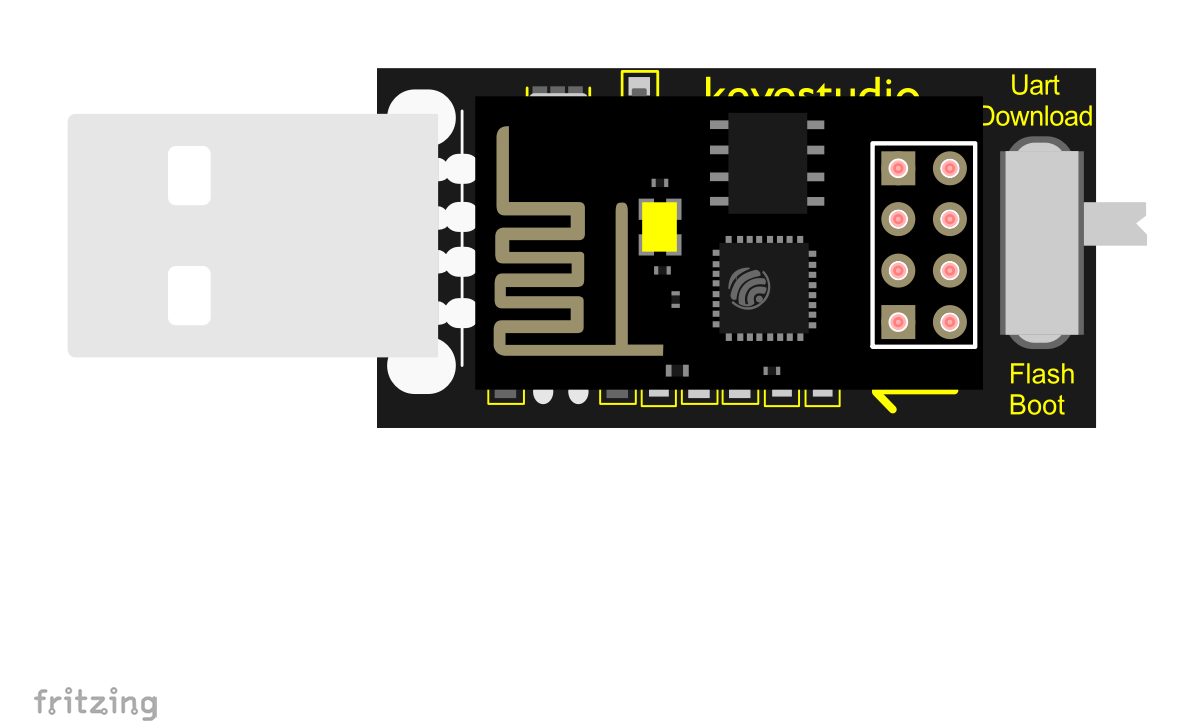

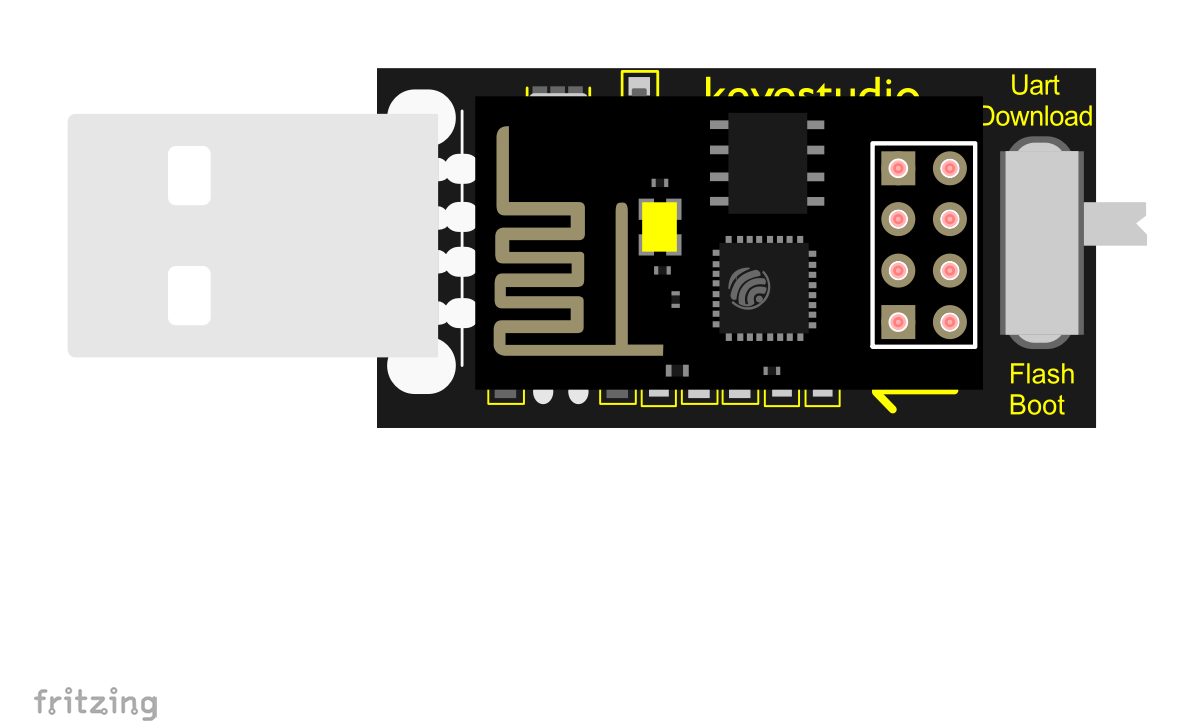

USB to ESP-01S WIFI Module Shieldx1 |

Stepper Motor Driver Boardx1 |

Stepper Motorx1 |

IR Remote Controlx1 |

|

|

|

|

|

Temperature and Humidity Sensorx1 |

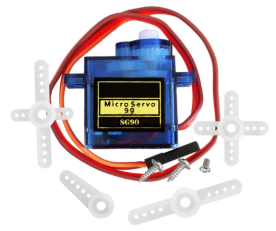

Servox1 |

Ultrasonic Sensorx1 |

5V Relay Modulex1 |

4x4 Membrane Keypadx1 |

|

|

|

|

|

Breadboard Wirex30 |

M-F Dupont Wirex20 |

F-F Dupont Wirex40 |

800-Hole Breadboardx1 |

USB Cablex1 |

|

||||

Resistance Cardx1 |

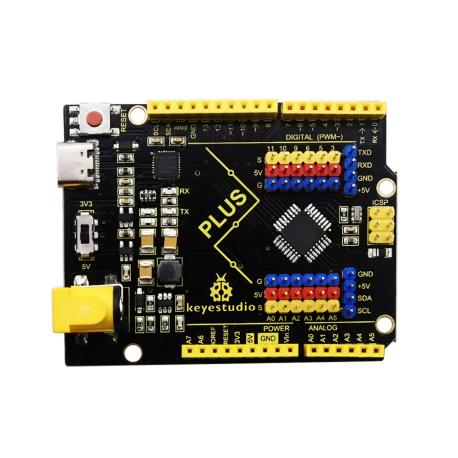

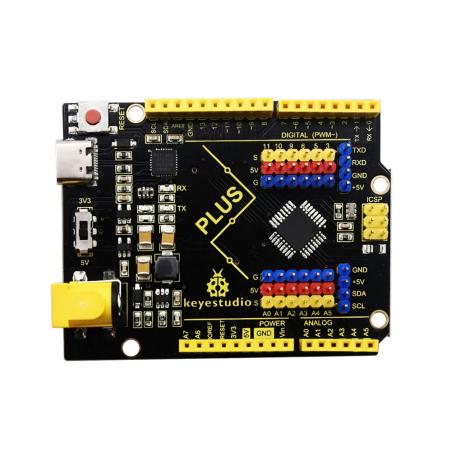

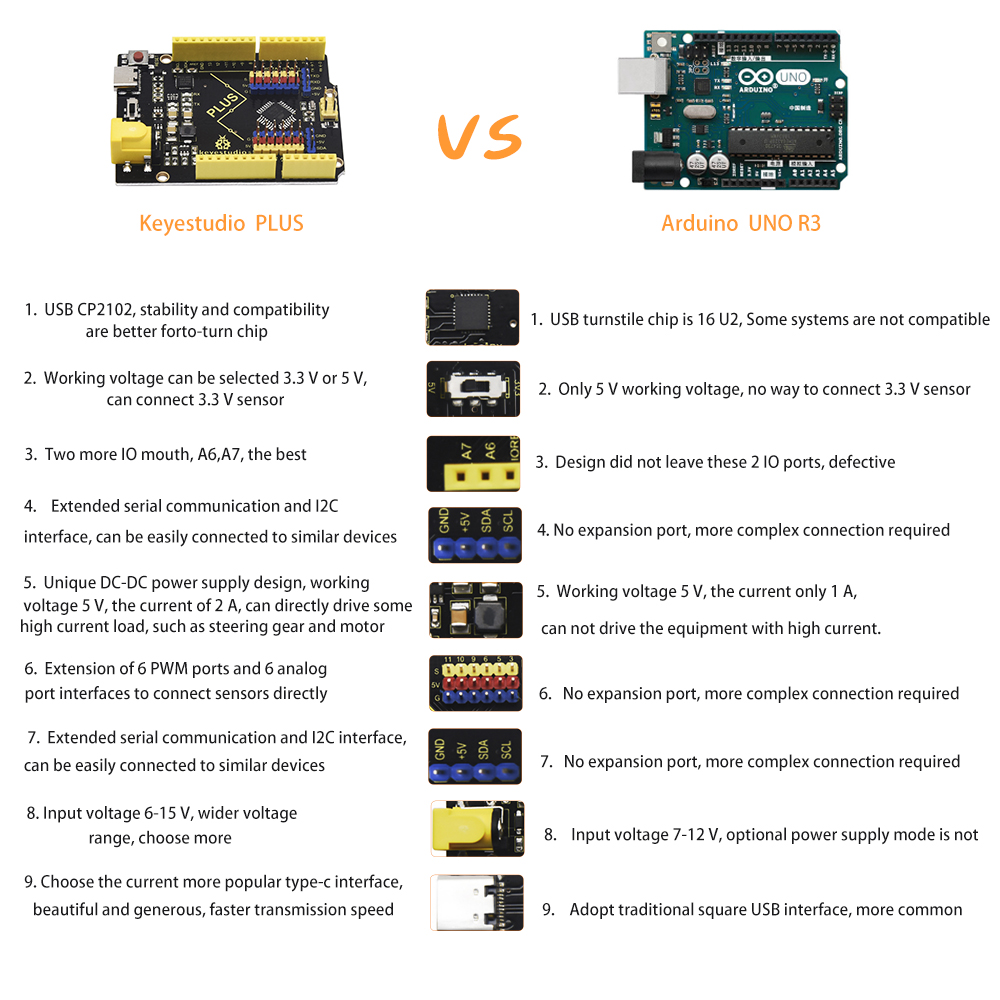

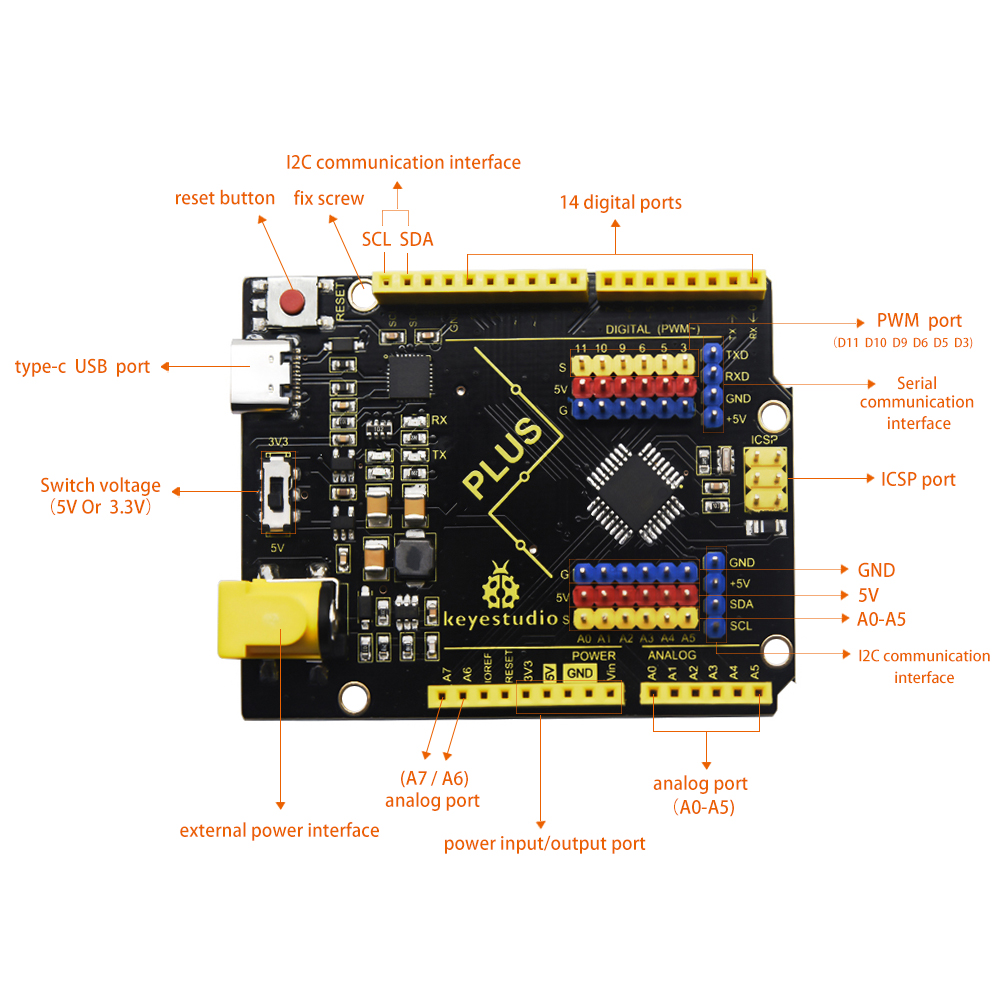

Keyestudio PLUS board

The Keyestudio PLUS motherboard, fully compatible with the Arduino IDE control board, which is the core of this kit

It incorporates all functions of Arduino UNO R3. Additionally, more improvements on the PLUS board makes it powerful.

It is your best choice to build up circuits and programme.

Specifications

Microcontroller: ATMEGA328P-AU

USB to serial chip: CP2102

Working voltage: DC 5V or 3.3V (DIP switch control)

External power supply: DC 6V to 15V (9V is recommended.)

Digital I/O pins: 14 (D0 to D13)

PWM channel: 6 (D3 D5 D6 D9 D10 D11)

Analog input channel (ADC): 8 (A0 to A7)

Each I/O port of DC output capacity: 20 mA

Output capacity of 3.3V port: 50 mA

Flash Memory: 32 KB(of which the bootloader uses 0.5 KB)

SRAM: 2 KB (ATMEGA328P-AU)

EEPROM:1 KB (ATMEGA328P-AU)

Clock speed: 16MHz

On-board LED pin: D13

Pinout

Specialized Functions of Pins:

Serial communication interface: D0 is RX, D1 is TX

PWM interface (pulse width modulation): D3 D5 D6 D9 D10 D11

External interrupt interface: D2(interrupt 0) and D3 (interrupt 1)

SPI communication interface: D10 is SS, D11 is MOSI, D12 is MISO, D13 is SCK

IIC communication port: A4 is SDA, A5 is SCL

Note: The all experiments of this learning kit, the DIP switch on the Keyestudio PLUS control board is turned to the 5V terminal by default.

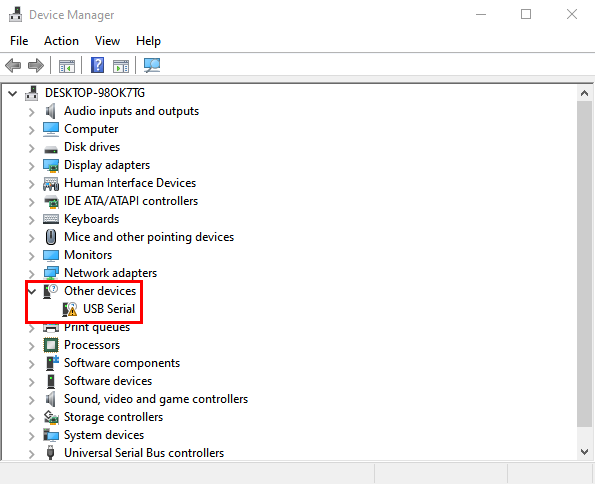

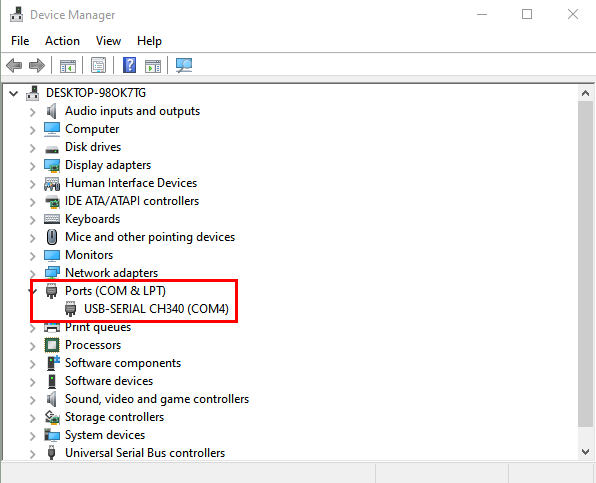

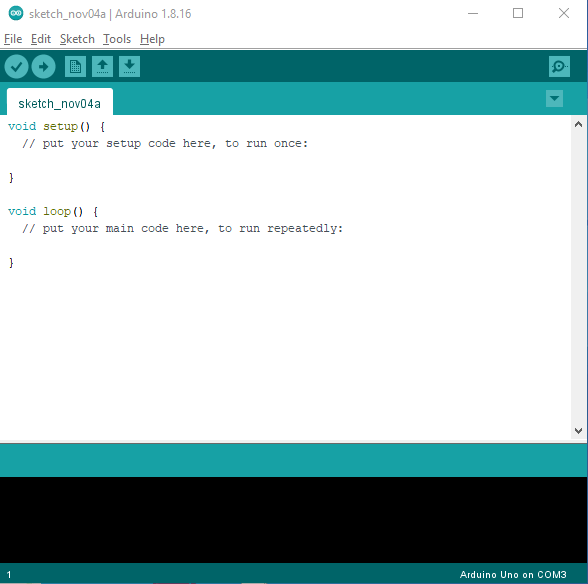

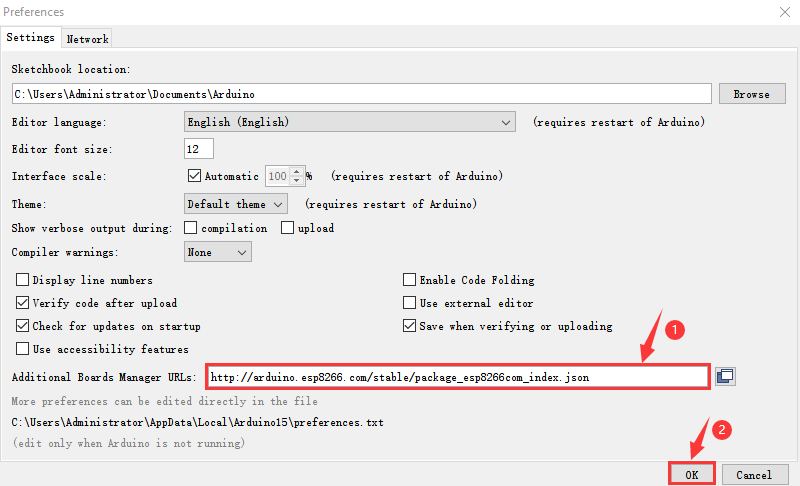

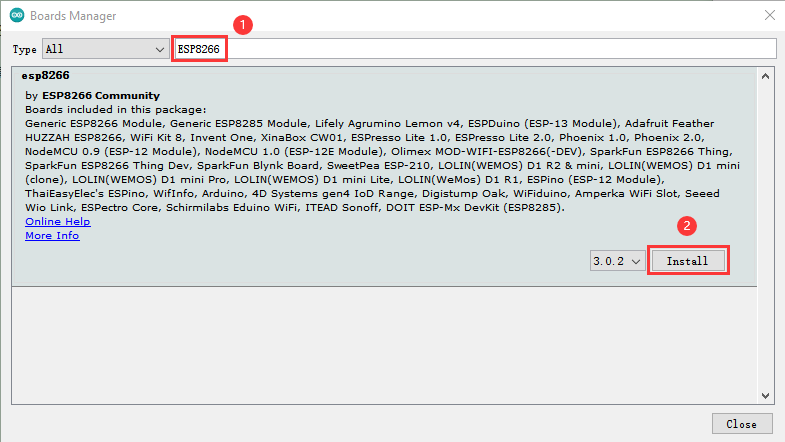

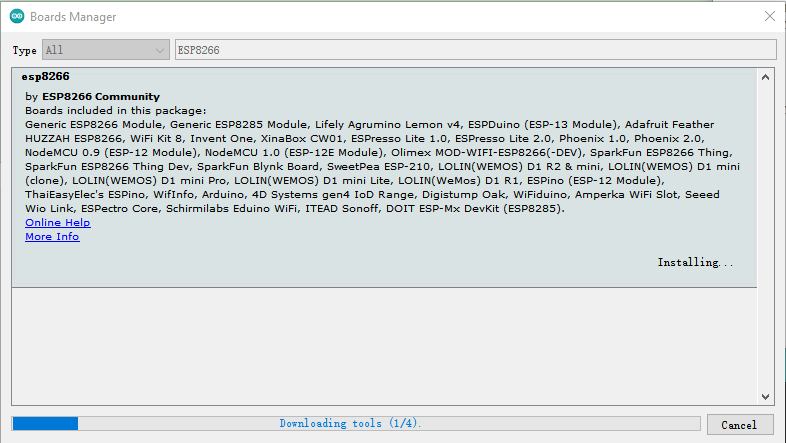

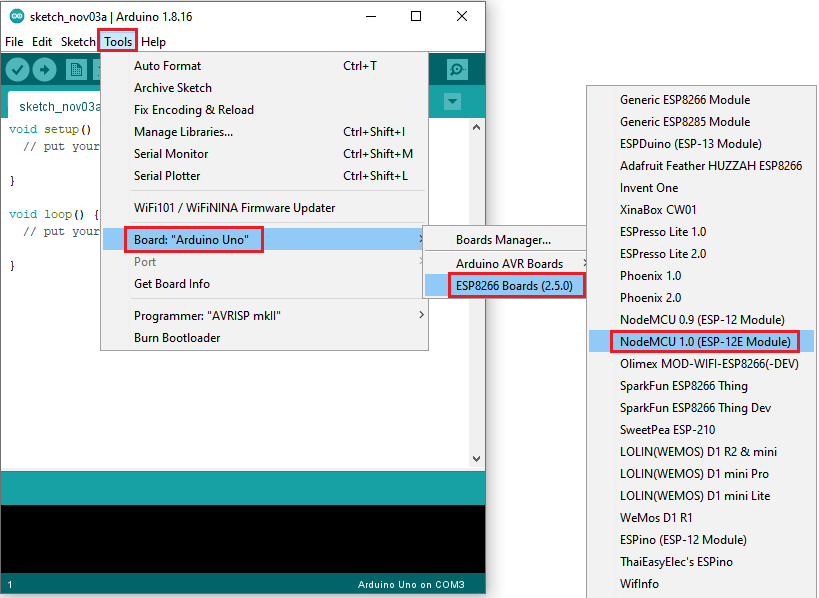

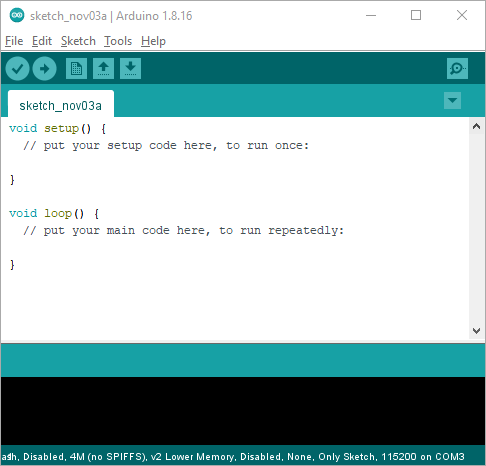

How to Download Arduino,Drivers and Library Files

Click the link to start learning how to download software, install drivers, upload code, and install library files.

Projects

Project 1: Hello World

Introduction

For Arduino beginners, we will start with some simple things. In this project, you only need a PLUS mainboard and a USB cable to complete the “Hello World!” project.

Components Required

|

|

|---|---|

Keyestudio PLUS Mainboardx1 |

USB Cablex1 |

Connection

Code

Arduino uses a serial monitor to display information such as print statements and sensor data. This is a very powerful tool for debugging long code. Let’s first learn the“if”statement, which is a control structure in Arduino programming.

/*

Keyestudio 2021 Starter Kit

Project 1

Hello World

http//www.keyestudio.com

*/

char val;// defines variable "val"

void setup()

{

Serial.begin(9600);// sets baudrate to 9600

}

void loop()

{

if (Serial.available() \> 0) {

val=Serial.read();// reads symbols assigns to "val"

if(val=='R')// checks input for the letter "R"

{ // if so,

Serial.println("Hello World!");// shows “Hello World !”.

}

}

}

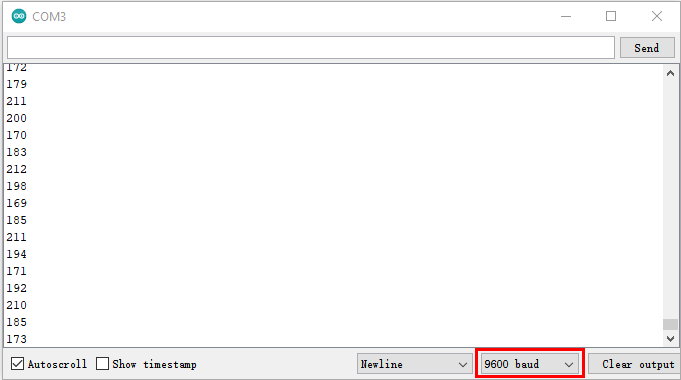

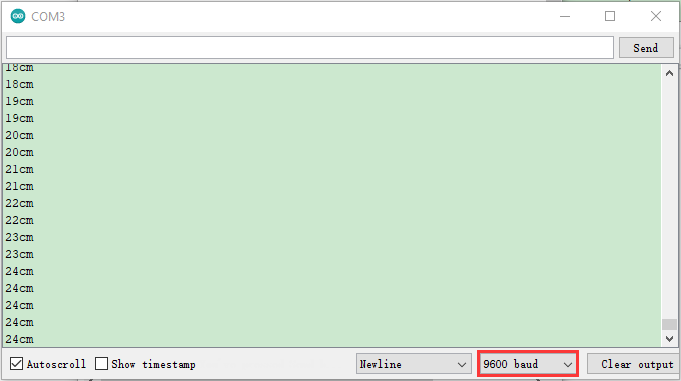

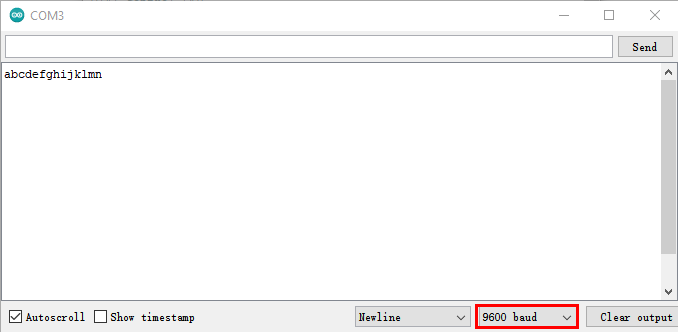

Result

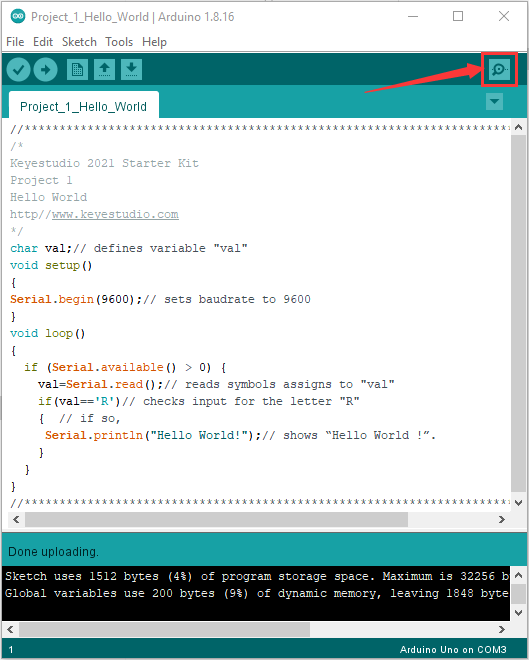

Select the correct Arduino IDE mainboard type and COM port, and click the button on the Arduino IDE to upload the code. After successfully uploading, click the icon

on the Arduino IDE to upload the code. After successfully uploading, click the icon to enter the serial display.

to enter the serial display.

Whenever you enter an “R” in the text box and click “Send”, the serial monitor will display “Hello World!”.

Project 2: LED Blinking

Introduction

In this project, we will show you the LED flashing effect through Arduino’s digital pins.

Components Required

|

|

|

|

|

|

|---|---|---|---|---|---|

Keyestudio PLUS Mainboardx1 |

Red LEDx1 |

220Ω Resistorx1 |

Breadboardx1 |

Jumper Wirex2 |

USB Cablex1 |

Component Knowledge

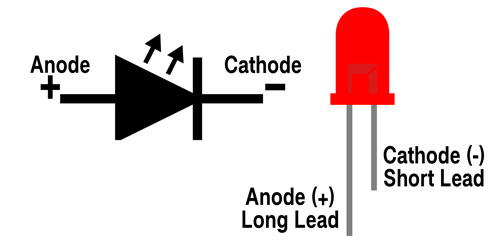

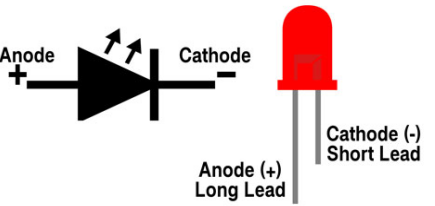

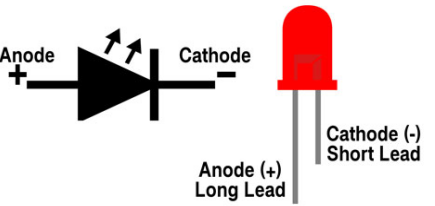

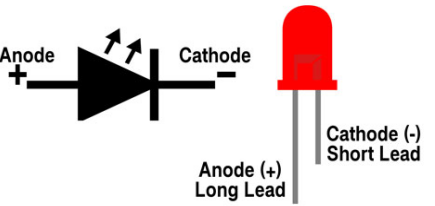

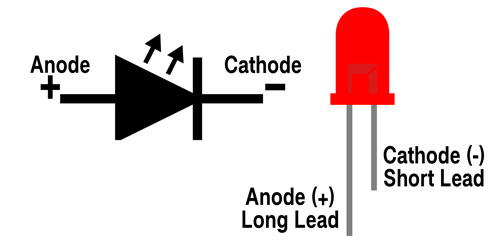

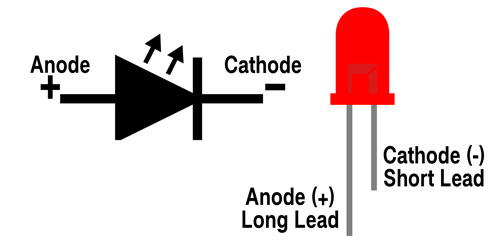

LED:

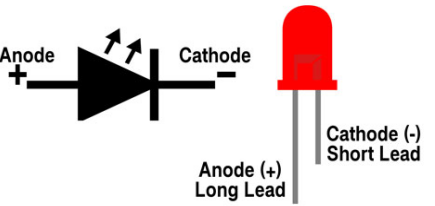

It is a kind of semiconductor called “light-emitting diode”, which is an electronic device made of semiconductor materials (silicon, selenium, germanium, etc.). It has an anode and a cathode. The short lead (cathode) is grounded. The long lead (anode) is connected to 5V.

Resistor

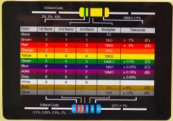

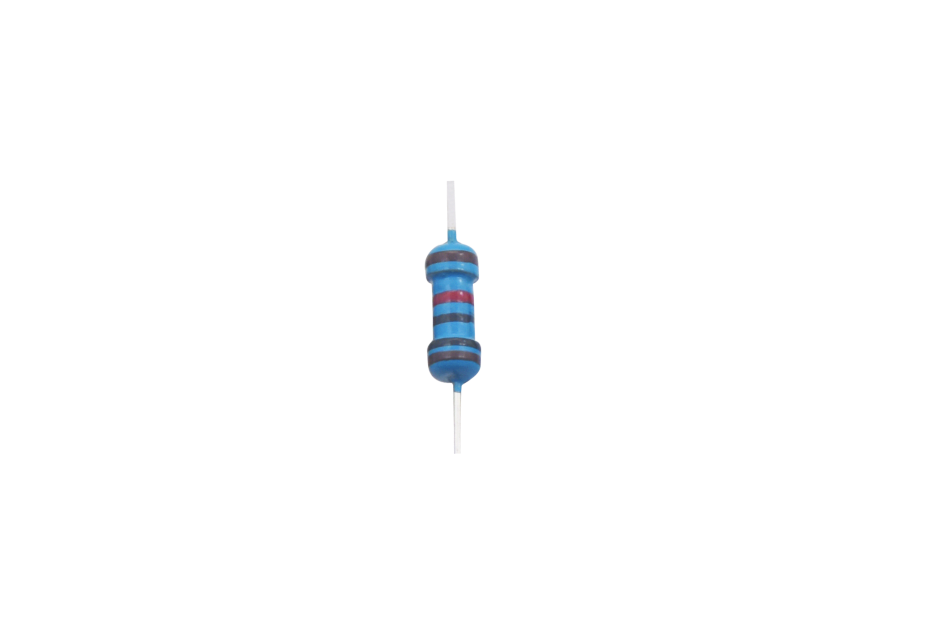

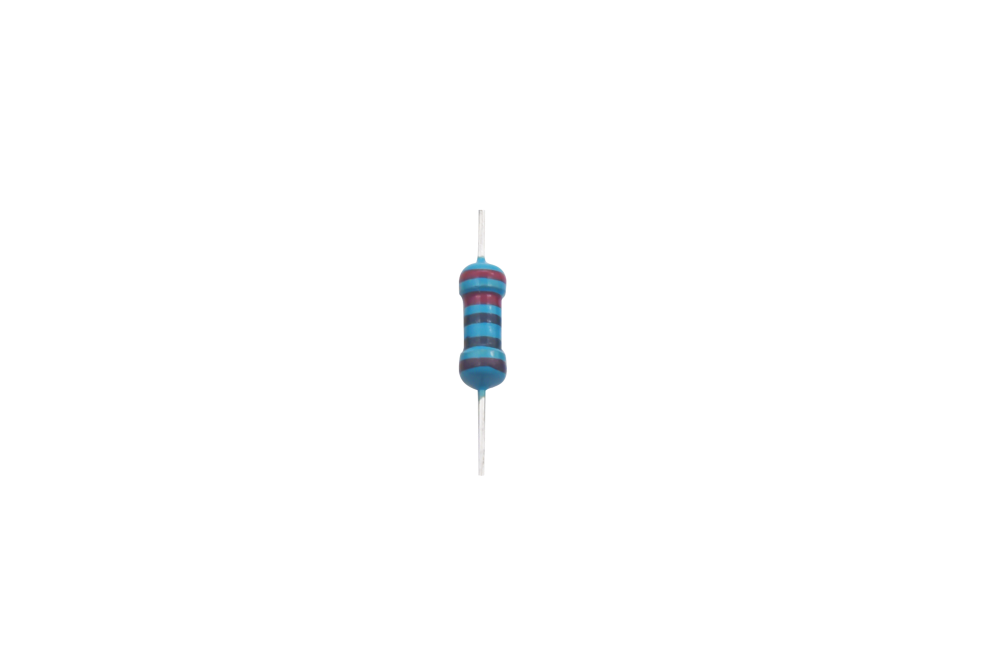

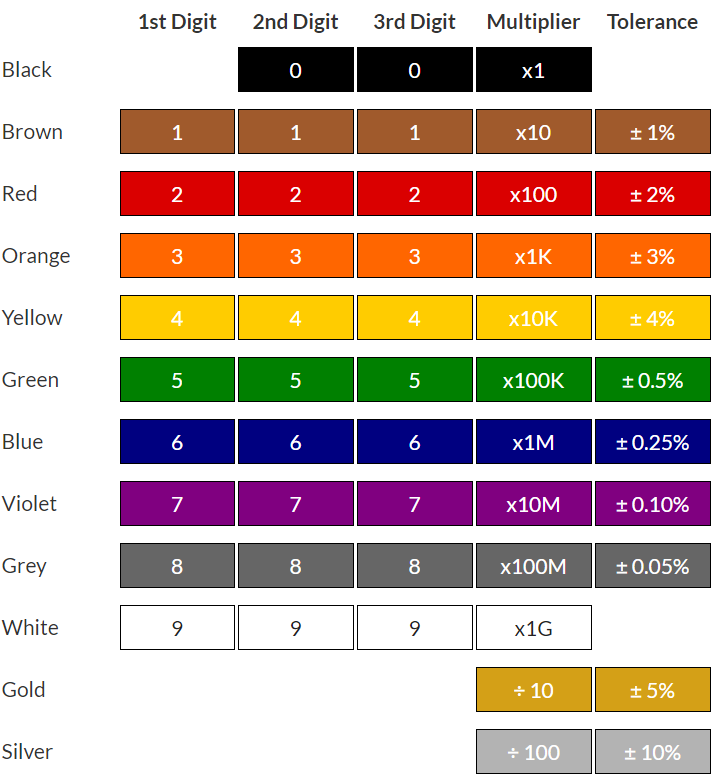

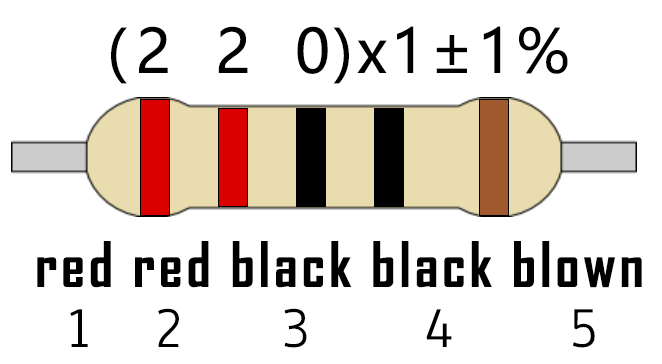

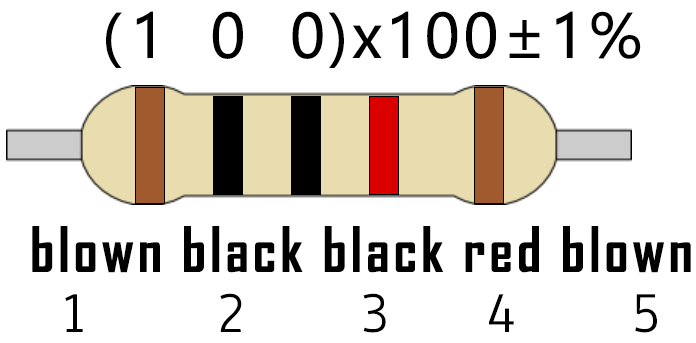

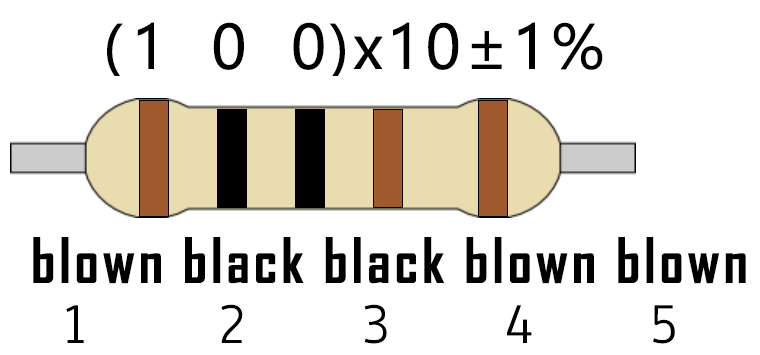

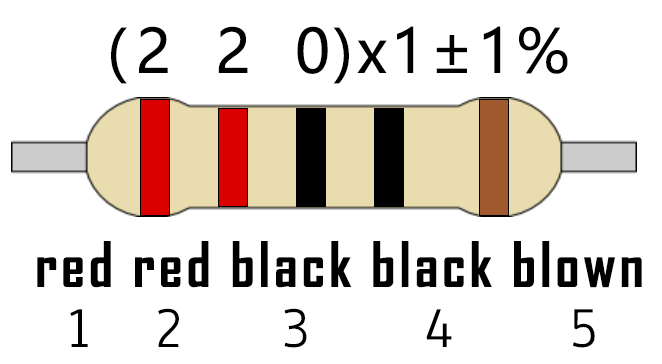

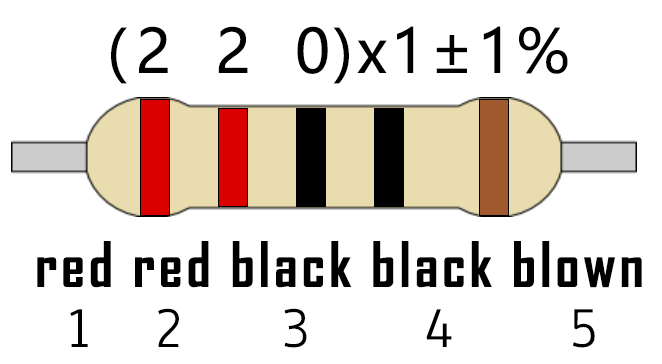

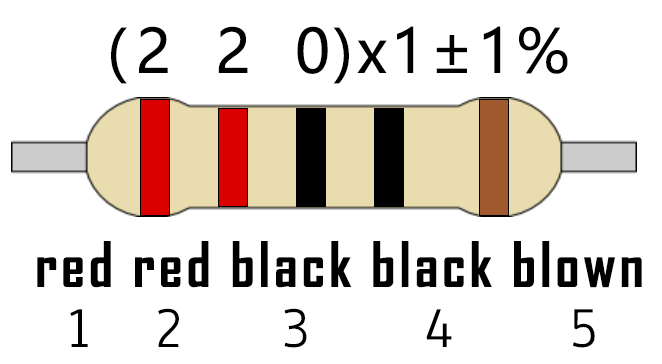

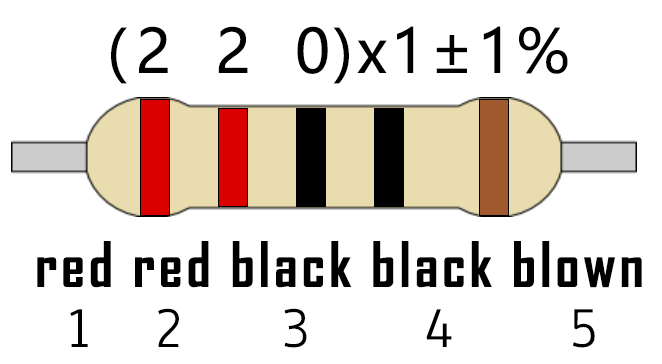

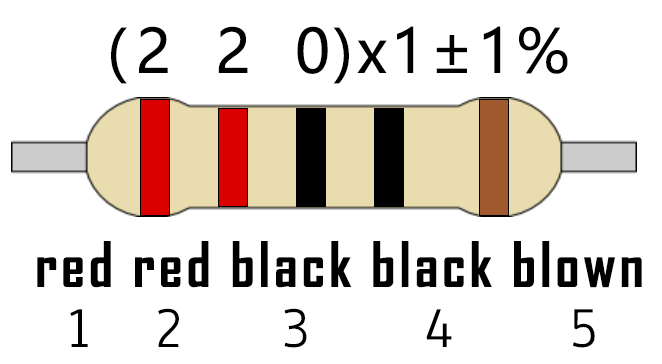

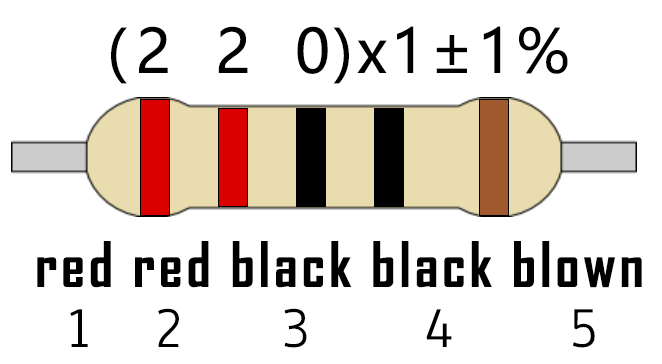

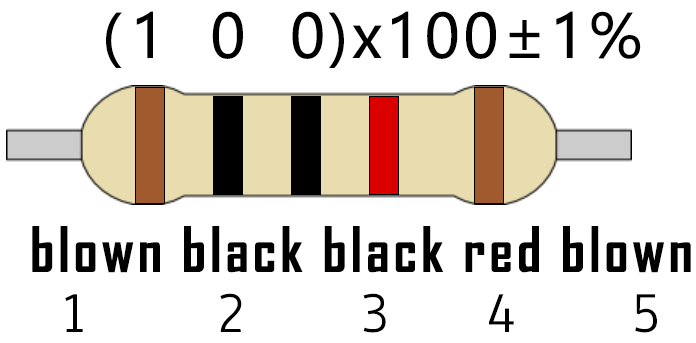

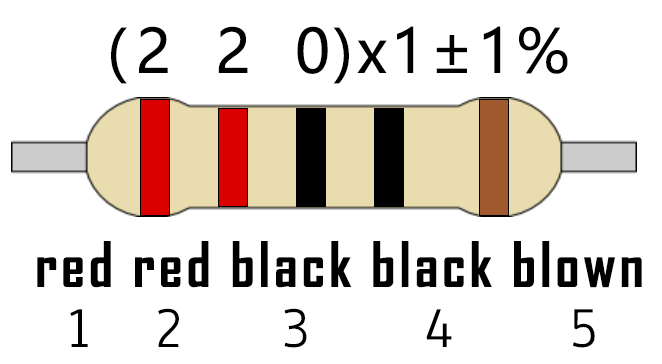

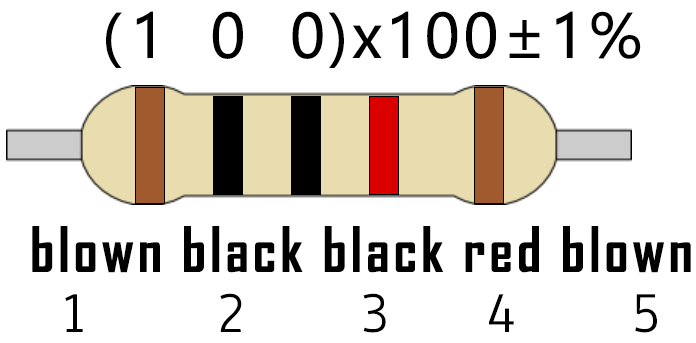

A resistor is an electronic component in a circuit that restricts or regulates the flow current flow. Its unit is(Ω).

We can use resistors to protect sensitive components, such as LEDs. The strength of the resistance is marked on the body of the resistor with an electronic color code. Each color code represents a number, and you can refer to it in a resistance card.

-Color 1 – 1st Digit

-Color 2 – 2nd Digit

-Color 3 – 3rd Digit

-Color 4 – Multiplier

-Color 5 – Tolerance

In this kit, we provide eight 5-band resistors with different resistance values. Take three 5-band resistors as an example.

220Ω resistorx10

10KΩ resistorx10

1KΩ resistorx10

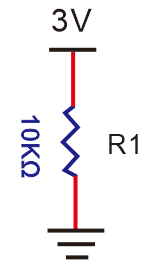

The connection between current, voltage, and resistance can be expressed by the formula: I=U/R.In the figure below, if the voltage is 3V, the current through R1 is: I = U / R = 3 V / 10 KΩ= 0.0003A= 0.3mA.

Do not directly connect resistors with very low resistance to the two poles of the power supply, as this will cause excessive current to damage the electronic components. Resistors do not have positive and negative poles.

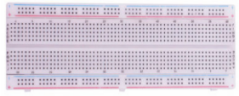

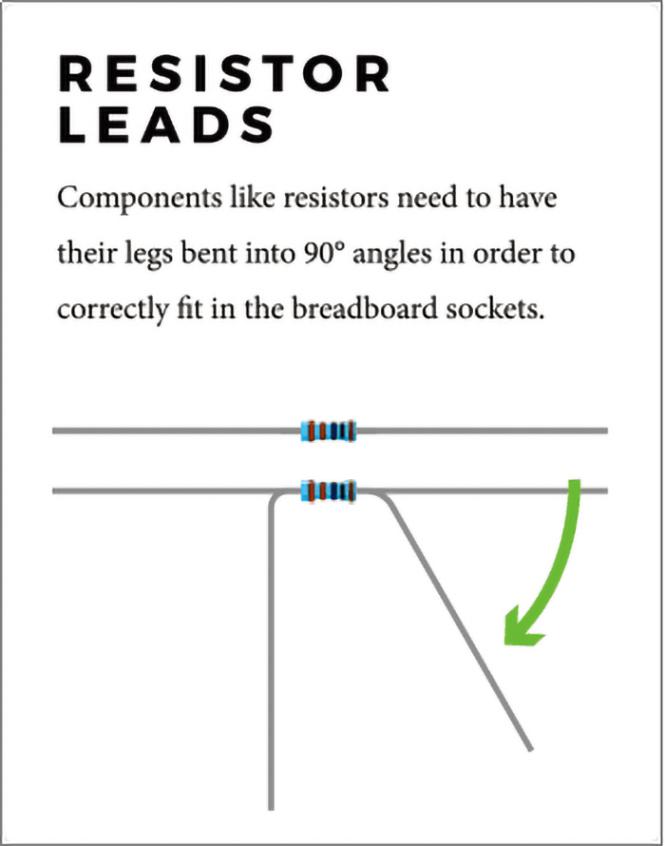

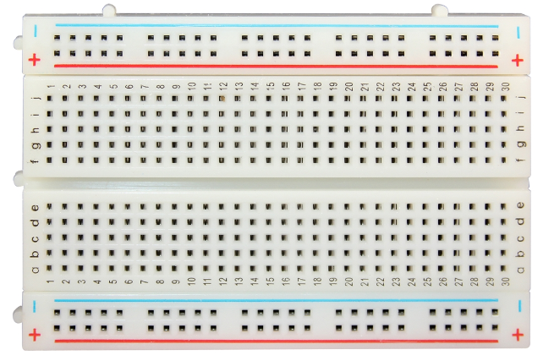

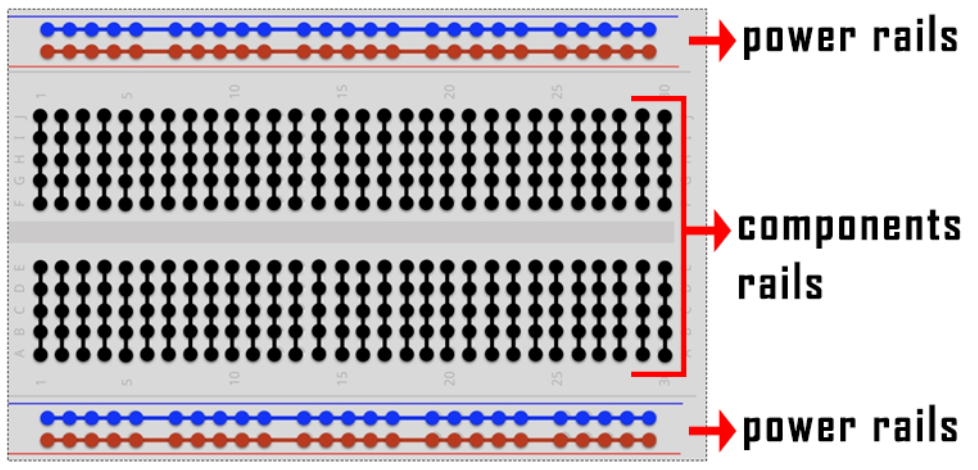

Breadboard

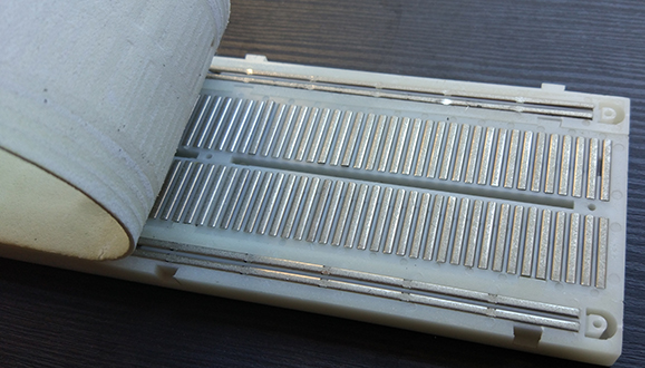

A breadboard is used to build and test circuits quickly before finalizing any circuit design. The breadboard has many holes into which circuit components like integrated circuits and resistors.A typical breadboard is as follows.

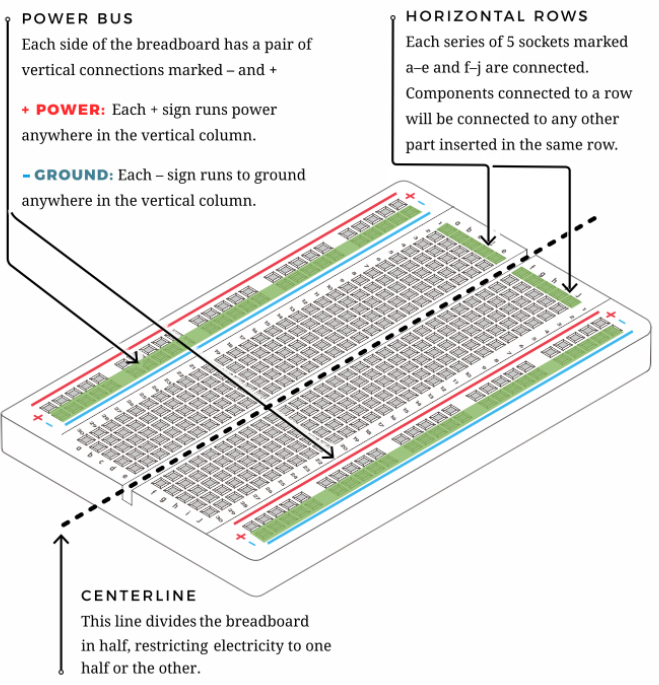

The bread board has strips of metal which run underneath the board and connect the holes on the top of the board. The metal strips are laid out as shown below. Note that the top and bottom rows of holes are connected horizontally while the remaining holes are connected vertically.

The first two rows (top) and the last two rows (bottom) of the breadboard are used for the positive (+) and negative (-) terminals of the power supply, respectively. The conductive layout of the breadboard is shown in the following diagram.

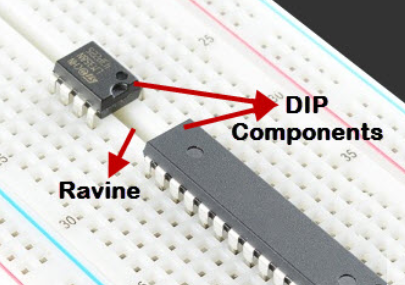

When we connect DIP (Dual In-line Packages) components, such as integrated circuits, microcontrollers, chips and so on, we can see that a groove in the middle isolates the middle part, so the top and bottom of the groove is not connected. DIP components can be connected as shown in the figure below.

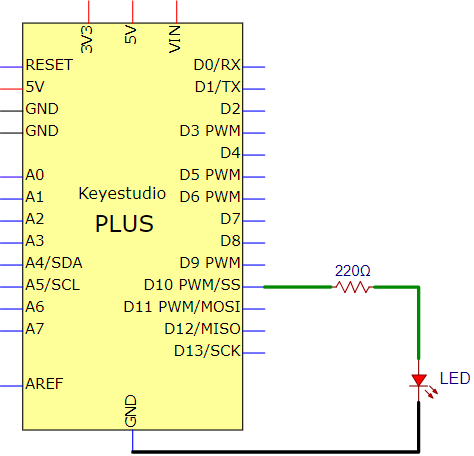

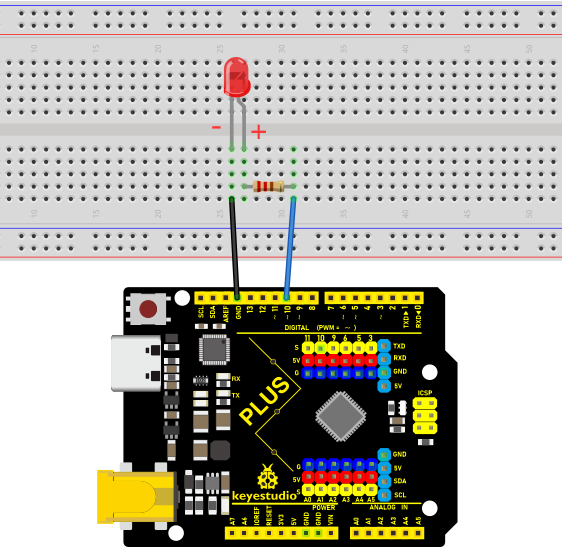

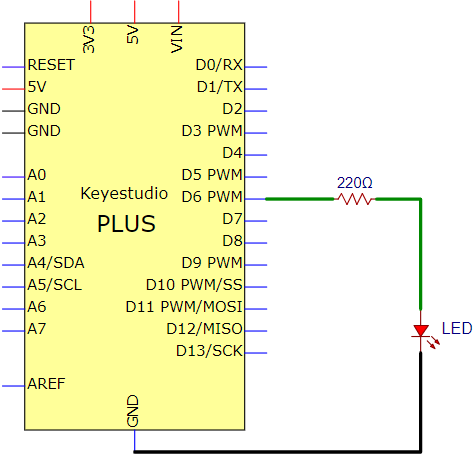

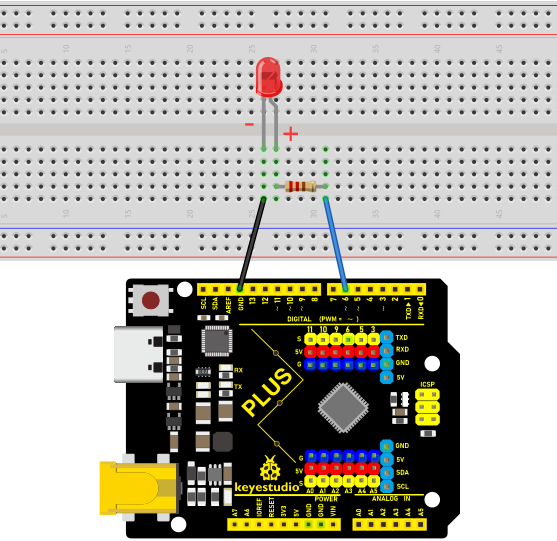

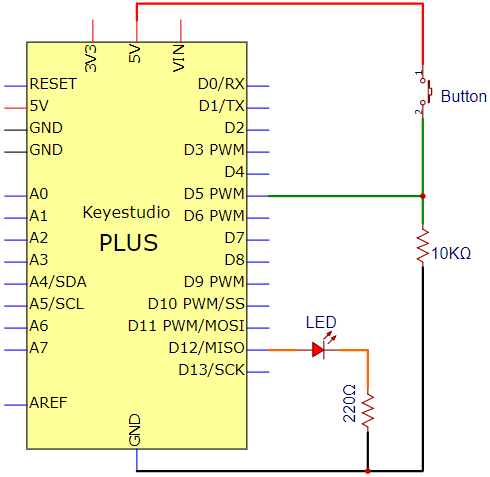

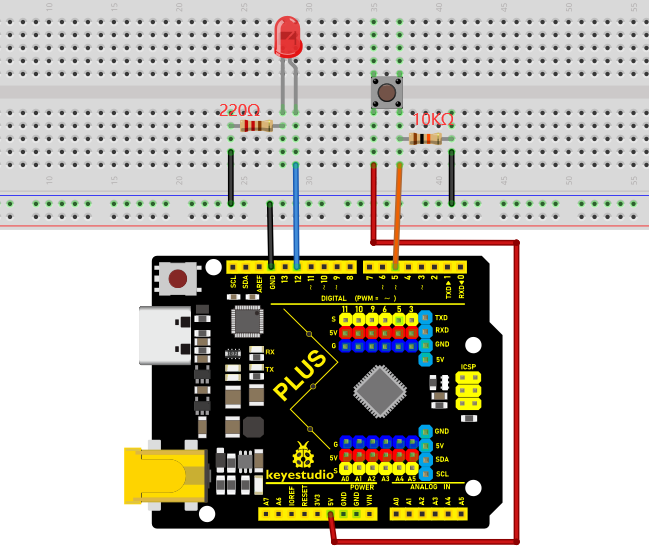

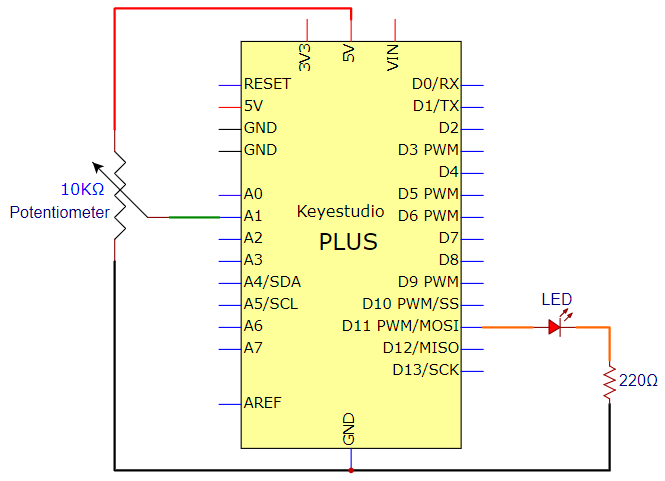

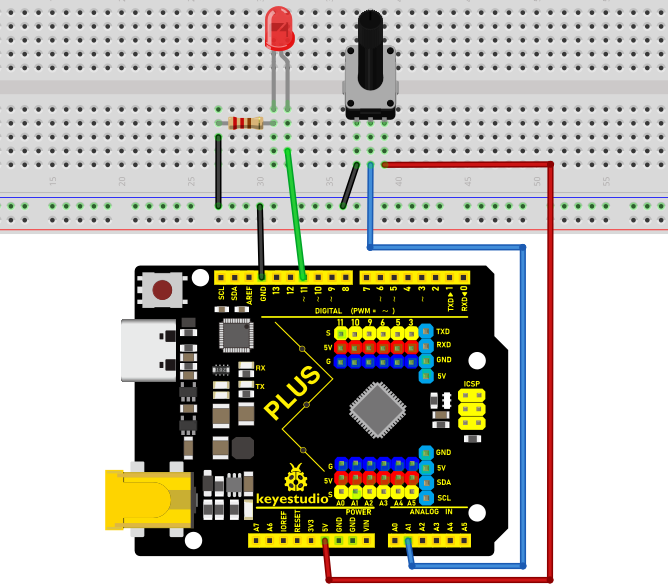

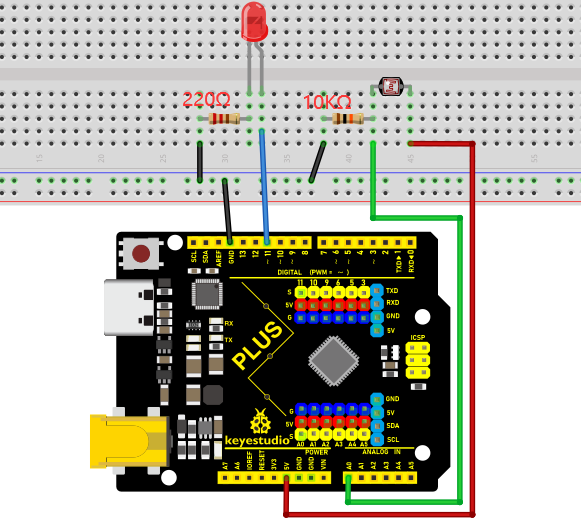

Circuit Diagram and Wiring Diagram

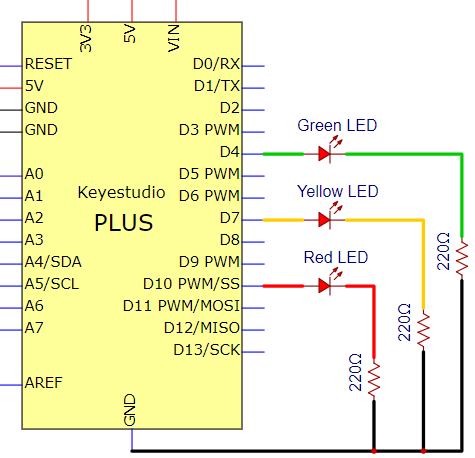

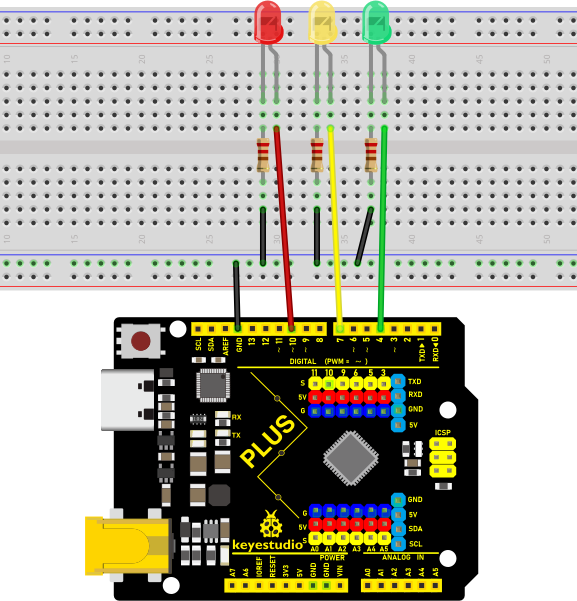

As shown in the diagram, we use digital pin 10 and connect one LED to a 220 ohm resistor to avoid high current damage to the LED.

Circuit Diagram

Wiring Diagram

Note:

How to connect an LED

How to identify the 220Ω five-band resistor

Code

/*

Keyestudio 2021 Starter Kit

Project 2

LED_Blinking

http//www.keyestudio.com

*/

int ledPin = 10; // defines numeric pin 10.

void setup()

{

pinMode(ledPin, OUTPUT);// defines PIN with connected LED as output

}

void loop()

{

digitalWrite(ledPin, HIGH); // turn on LED

delay(1000); // wait a second.

digitalWrite(ledPin, LOW); // turn off LED

delay(1000); // wait a second

}

Result

Upload the project code, wire up components according to the wiring diagram, and power on. The LED will blink.

Explanation

pinMode(ledPin,OUTPUT): Before using the Arduino’s pins, you need to tell the control board whether it is INPUT or OUTPUT. We use a built-in function “pinMode()” to do this.

digitalWrite(ledPin,HIGH) : When using a pin as an OUTPUT, it can be commanded as HIGH (output 5V) or LOW (output 0V).

Project 3: Breathing Led

Introduction

In this project, we will learn the PWM control of ARDUINO. PWM is Pulse Width Modulation, which is a technique that encodes analog signal levels into digital signal levels. We will use PWM to control the brightness of LED.

Components Required

|

|

|

|

|

|

|---|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Red LEDx1 |

220Ω Resistorx1 |

Breadboardx1 |

Jumper Wirex2 |

USB Cablex1 |

Component Knowledge

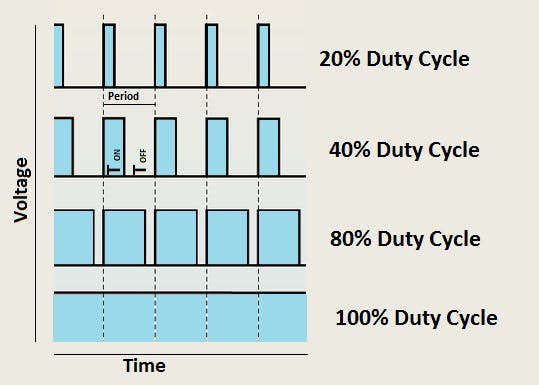

Working principle: It can control the brightness of LED, the speed of DC motors and Servo motors, and outputs square wave signal. If we want to dim the LED, we can change the ON(open) and OFF(close) time of the signal. When we change the time of ON and OFF fast enough, then the brightness of the LED will change. Here are some terms related to PWM as follows.

ON (open):When the signal is high.

OFF (close):When the signal is low.

Period: It is the sum of the time of On and Off.

Duty cycle: The percentage of time when the signal is at a high level for a certain period of time. At 50% duty cycle and 1Hz frequency, the LED will be on for half a second and off for the other half of a second.

Arduino and PWM

The Arduino IDE has a built-in function “analogWrite()” that can be used to generate PWM signals. Most of the pins generate signals with a frequency of about 490Hz and we can use this function to give values from 0 to 255.

“analogWrite(0)” indicates a signal with 0% duty cycle. “analogWrite(127)” indicates a signal with 50% duty cycle.

“analogWrite(255)” indicates a signal with 100% duty cycle. On the Plus control board, the PWM pins are 3, 5, 6, 9,10, and 11. PWM pins are marked with the “~”symbol. In this project, you will learn how to get the PWM output from the digital pins of the Plus control board and control the brightness of the LED by code.

Circuit Diagram and Wiring Diagram

Note:

How to connect the LED

How to identify the 220Ω 5-band resistor

Code

/*

Keyestudio 2021 Starter Kit

Project 3

Breathing_Led

http//www.keyestudio.com

*/

int ledPin = 6;

void setup()

{

pinMode(ledPin,OUTPUT);

}

void loop(){

for (int value = 0 ; value \< 255; value=value+1){

analogWrite(ledPin, value);

delay(5);

}

for (int value = 255; value \>0; value=value-1){

analogWrite(ledPin, value);

delay(5);

} }

Result

After burning the project code, connecting the wires according to the wiring diagram, and powering on, the LED lights up gradually, and then gradually darkens.

Explanation

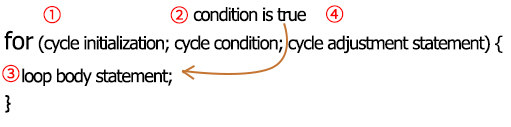

When we need to execute a sentence repeatedly, we can use the “for” statement.

The “for”statement format is as follows:

The loop sequence of“for”statement is as follows:

Round 1: 1 → 2 → 3 → 4

Round 2: 2 → 3 → 4

…

Until 2 does not hold and the “for” statement loop ends. Knowing this sequence, go back to the code.

for (int value = 0; value < 255; value=value+1){

…}

for (int value = 255; value >0; value=value-1){

…}

These two for statements, which realize that the value can continuously increases from 0 to 255, then decreases from 255 to 0. The loop continues indefinitely.

In the “for”statement, involving a new function “analogWrite()”.

We know that the digital port has only two states, 0 and 1. How to send an analog value to a digital pin? This function will be used. Take a look at the Arduino board and look at the digital pins. You will find that 6 of the pins are marked with “~”. These pins are different from other pins in that they can output PWM signals.

The format as follow:

analogWrite(pin,value)

The “analogWrite()” function is used to input an analog value from 0 to 255 to the PWM port. Therefore, the value is between 0 and 255. Note that the “analogWrite()” function can only write to the digital pins with PWM function, that is, the 3, 5, 6, 9, 10, and 11 pins.

Project 4: Traffic Light

Introduction

Traffic lights are closely related to people’s daily lives. Traffic lights generally show red, yellow, and green. Everyone should obey the traffic rules, which can avoid many traffic accidents. In this project, we will use a PLUS board and some LEDs (red, green and yellow) to simulate the traffic lights.

Components Required

|

|

|

|

|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Red LEDx1 |

Yellow LEDx1 |

Green LEDx1 |

|

|

|

|

USB Cablex1 |

220Ω Resistorx3 |

Breadboardx1 |

Jumper Wires |

Circuit Diagram and Wiring Diagram

Note:

How to connect an LED

How to identify the 220Ω 5-band resistor

Code

The flashing time of each LED should be the same as the traffic lights. In this program, we use “Arduino delay ()” to control the delay time.

/*

Keyestudio 2021 Starter Kit

Project 4

Traffic_Light

http//www.keyestudio.com

*/

int redled =10; // initializes digital PIN 10

int yellowled =7; // initializes digital PIN 7

int greenled =4; // initializes digital PIN 4

void setup()

{

pinMode(redled, OUTPUT);// sets digital PIN 10 to “output”

pinMode(yellowled, OUTPUT); // sets digital PIN 7 to “output”

pinMode(greenled, OUTPUT); // sets digital PIN 4 to “output”

}

void loop()

{

digitalWrite(greenled, HIGH);// turns on LED

delay(5000);// delays 5 seconds

digitalWrite(greenled, LOW); // turns off LED

for(int i=0;i\<3;i++)// flashes 3 times.

{

delay(500);// delays 0.5 second

digitalWrite(yellowled, HIGH);// turns on LED

delay(500);// delays 0.5 second

digitalWrite(yellowled, LOW);// turns off LED

}

delay(500);// delays 0.5 second

digitalWrite(redled, HIGH);// turns on LED

delay(5000);// delays 5 second

digitalWrite(redled, LOW);// turns off LED

}

Result

Upload the code and power on, the green LED will light up for 5s then go off. Next, the yellow one will blink for 3 times and red LED will be on for 5s then go off.

Project 5: RGB LED

Introduction

In this project, we will introduce the RGB LED and show you how to use the Plus control board to control the RGB LED. Even though RGB LED is very basic, it is also a great way to learn the fundamentals of electronics and coding.

Components Required

|

|

|

|

|

|

|---|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

RGB LEDx1 |

220Ω Resistorx3 |

Breadboardx1 |

Jumper Wires |

USB Cablex1 |

Component Knowledge

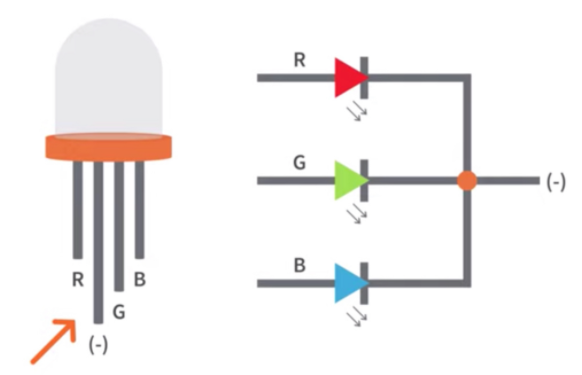

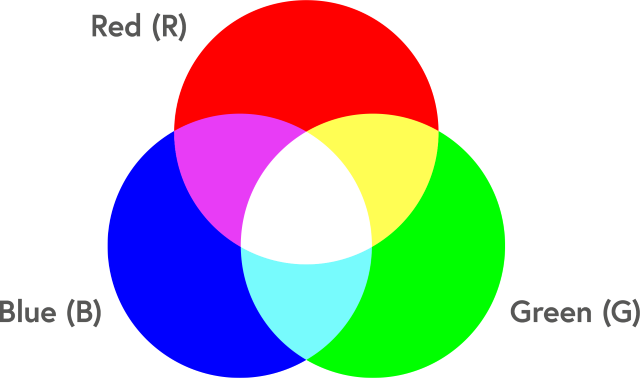

RGB LED:

The monitors mostly adopt the RGB color standard, and all the colors on the computer screen are composed of the three colors of red, green and blue mixed in different proportions.

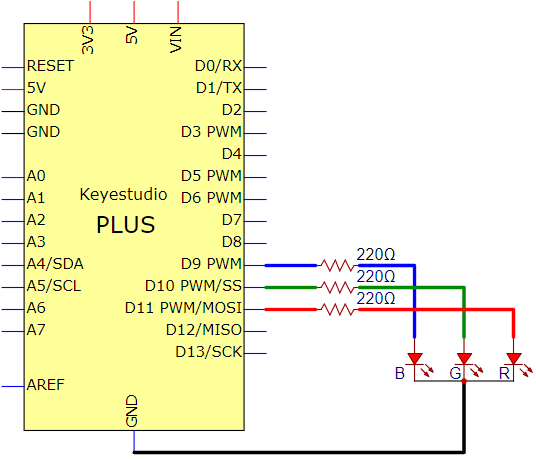

This RGB LED has pin R, G and B and a common cathode. To change its brightness, we can use the PWM pins which can give different duty cycle signals to the RGB LED to produce different colors.

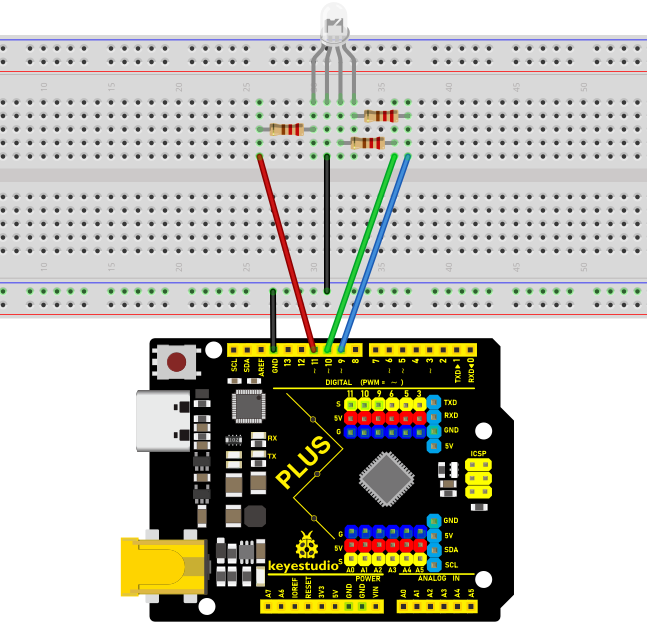

Circuit Diagram and Wiring Diagram

Note:

RGB LED longest pin (common cathode) connected to GND.

How to identify the 220Ω 5-band resistor

Code

/*

Keyestudio 2021 starter learning kit

Project 5

RGB LED

http//www.keyestudio.com

*/

int redpin = 11; // select the pin for the red LED

int bluepin =9; // select the pin for the blue LED

int greenpin =10;// select the pin for the green LED

int val;

void setup() {

pinMode(redpin, OUTPUT);

pinMode(bluepin, OUTPUT);

pinMode(greenpin, OUTPUT);

}

void loop()

{

for(val=255; val\>0; val--)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

for(val=0; val\<255; val++)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

}

Result

Upload the project code, wire up, power up and wait a few seconds, you will see a colorful LED.

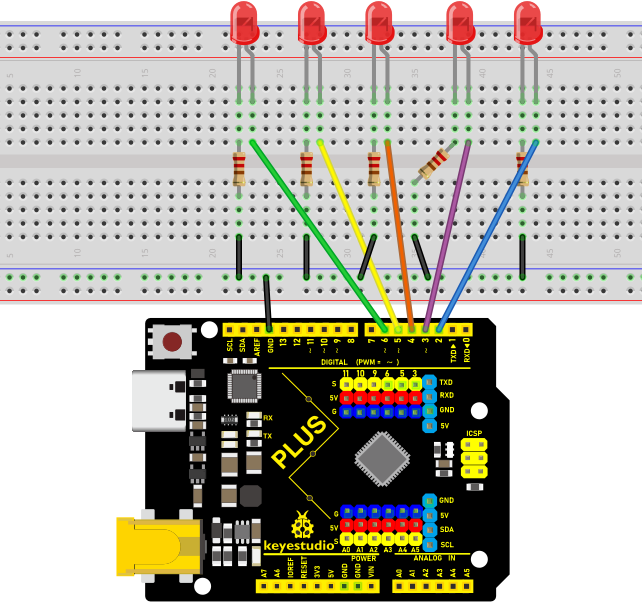

Project 6: Flowing Light

Introduction

In our daily life, we can see many billboards made up of different colors of LED. They constantly change the light to attract the attention of customers. In this project, we will use Plus control board with 5 LEDs to achieve the effect of flowing water.

Components Required

|

|

|

|

|

|

|---|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Red LEDx5 |

220Ω Resistorx5 |

Breadboard x1 |

Jumper Wires |

USB Cablex1 |

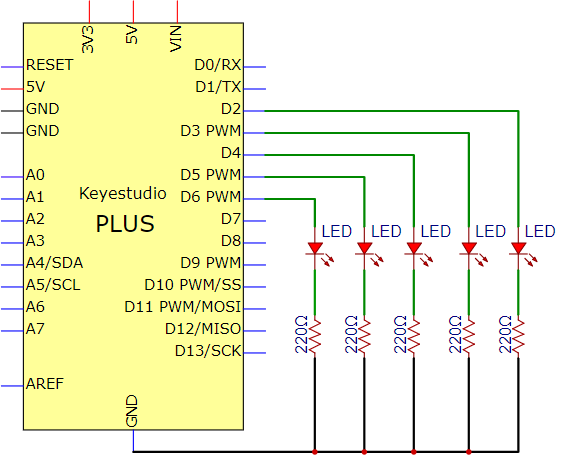

Circuit Diagram and Wiring Diagram

Note:

How to connect the LED

How to identify the 220Ω 5-band resistor

Code

/*

Keyestudio 2021 Starter Kit

Project 6

Flowing_Light

http//www.keyestudio.com

*/

int BASE = 2 ;// I/O PIN for the first LED

int NUM = 5; // amount of LEDs

void setup()

{

for (int i = BASE; i \< BASE + NUM; i ++)

{

pinMode(i, OUTPUT); // sets I/O PIN to "output"

}

}

void loop()

{

for (int i = BASE; i \< BASE + NUM; i ++)

{

digitalWrite(i, LOW); //sets I/O PIN to "low", turns off LEDs one after the

other

delay(200); // delay

}

for (int i = BASE; i \< BASE + NUM; i ++)

{

digitalWrite(i, HIGH); // sets I/O PIN to "high", turns on LEDs one after

the other

delay(200); // delay

}

}

Result

After burning the project code, connecting the wires and powering on, the 5 LEDs connected to the D2 to D6 pins of the development board will gradually light up and then gradually go off, just like a battery charge.

Project 7: Active Buzzer

Introduction

Active buzzer is a sound making element, widely used on computers, printers, alarms, electronic toys, telephones, timers, etc. It has an inner vibration source. In this project, we will use a PLUS control board to control the active buzzer to buzz.

Components Required

|

|

|

|

|

|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Active Buzzerx1 |

Breadboard x1 |

Jumper Wires |

USB Cablex1 |

Component Knowledge

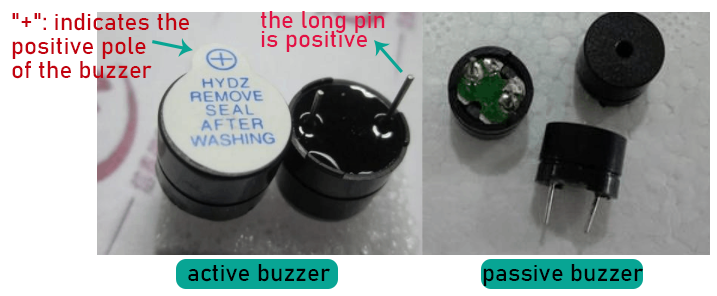

The active buzzer inside has a simple oscillator circuit which can convert constant direct current into a certain frequency pulse signal. Once active buzzer receives a high level, it will sound. The passive buzzer is an integrated electronic buzzer with no internal vibration source. It must be driven by 2K to 5K square wave instead of a DC signal. The appearance of the two buzzers is very similar, but passive buzzers come with a green circuit board, and active buzzers come with a black tape. Passive buzzers don’t have positive pole, but active buzzers have.

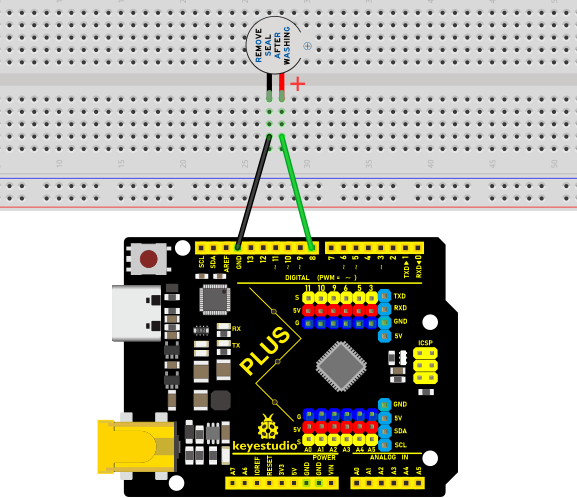

Circuit Diagram and Wiring Diagram

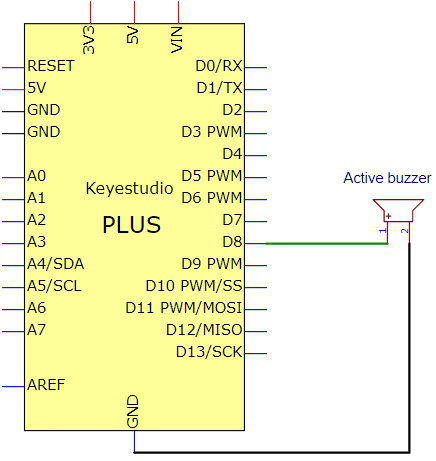

Note: The positive terminal (“+”/long pin) of the active buzzer is connected to pin 8, and the negative terminal (short pin) is connected to GND.

Code

/*

Keyestudio 2021 Starter Kit

Project 7

Active_buzzer

http//www.keyestudio.com

*/

int buzzerPin = 8;

void setup ()

{

pinMode (buzzerPin, OUTPUT);

}

void loop ()

{

digitalWrite (buzzerPin, HIGH);

delay (500);

digitalWrite (buzzerPin, LOW);

delay (500);

}

Result

Upload the project code, wire up and power up, then the active buzzer buzzes.

Project 8: Passive Buzzer

Introduction

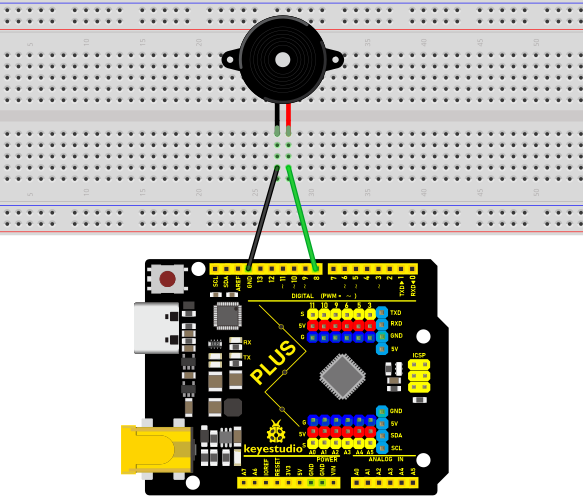

In this project, we will learn the passive buzzer and use the Plus control board to control the passive buzzer to play a song. Unlike an active buzzer, a passive buzzer can emit sounds of different frequencies.

Components Required

|

|

|

|

|

|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Passive Buzzerx1 |

Breadboardx1 |

Jumper Wires |

USB Cablex1 |

Component Knowledge

A passive buzzer is an integrated electronic buzzer with no internal vibration source. It must be driven by 2K to 5K square wave, not a DC signal. The two buzzers are very similar in appearance, but one buzzer with a green circuit board is a passive buzzer, while the other with black tape is an active buzzer. Passive buzzers cannot distinguish between positive polarity while active buzzers can.

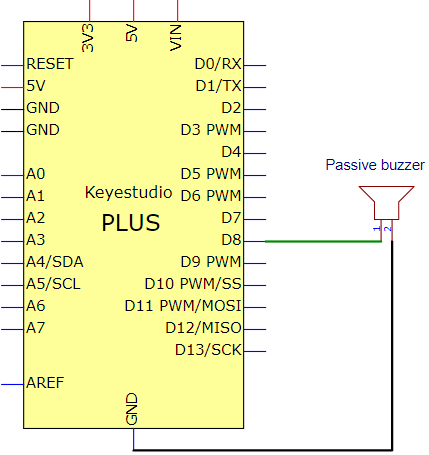

Circuit Diagram and Wiring Diagram

Code

/*

Keyestudio 2021 Starter Kit

Project 8

Passive_buzzer

http//www.keyestudio.com

*/

\#define NOTE_B0 31

\#define NOTE_C1 33

\#define NOTE_CS1 35

\#define NOTE_D1 37

\#define NOTE_DS1 39

\#define NOTE_E1 41

\#define NOTE_F1 44

\#define NOTE_FS1 46

\#define NOTE_G1 49

\#define NOTE_GS1 52

\#define NOTE_A1 55

\#define NOTE_AS1 58

\#define NOTE_B1 62

\#define NOTE_C2 65

\#define NOTE_CS2 69

\#define NOTE_D2 73

\#define NOTE_DS2 78

\#define NOTE_E2 82

\#define NOTE_F2 87

\#define NOTE_FS2 93

\#define NOTE_G2 98

\#define NOTE_GS2 104

\#define NOTE_A2 110

\#define NOTE_AS2 117

\#define NOTE_B2 123

\#define NOTE_C3 131

\#define NOTE_CS3 139

\#define NOTE_D3 147

\#define NOTE_DS3 156

\#define NOTE_E3 165

\#define NOTE_F3 175

\#define NOTE_FS3 185

\#define NOTE_G3 196

\#define NOTE_GS3 208

\#define NOTE_A3 220

\#define NOTE_AS3 233

\#define NOTE_B3 247

\#define NOTE_C4 262

\#define NOTE_CS4 277

\#define NOTE_D4 294

\#define NOTE_DS4 311

\#define NOTE_E4 330

\#define NOTE_F4 349

\#define NOTE_FS4 370

\#define NOTE_G4 392

\#define NOTE_GS4 415

\#define NOTE_A4 440

\#define NOTE_AS4 466

\#define NOTE_B4 494

\#define NOTE_C5 523

\#define NOTE_CS5 554

\#define NOTE_D5 587

\#define NOTE_DS5 622

\#define NOTE_E5 659

\#define NOTE_F5 698

\#define NOTE_FS5 740

\#define NOTE_G5 784

\#define NOTE_GS5 831

\#define NOTE_A5 880

\#define NOTE_AS5 932

\#define NOTE_B5 988

\#define NOTE_C6 1047

\#define NOTE_CS6 1109

\#define NOTE_D6 1175

\#define NOTE_DS6 1245

\#define NOTE_E6 1319

\#define NOTE_F6 1397

\#define NOTE_FS6 1480

\#define NOTE_G6 1568

\#define NOTE_GS6 1661

\#define NOTE_A6 1760

\#define NOTE_AS6 1865

\#define NOTE_B6 1976

\#define NOTE_C7 2093

\#define NOTE_CS7 2217

\#define NOTE_D7 2349

\#define NOTE_DS7 2489

\#define NOTE_E7 2637

\#define NOTE_F7 2794

\#define NOTE_FS7 2960

\#define NOTE_G7 3136

\#define NOTE_GS7 3322

\#define NOTE_A7 3520

\#define NOTE_AS7 3729

\#define NOTE_B7 3951

\#define NOTE_C8 4186

\#define NOTE_CS8 4435

\#define NOTE_D8 4699

\#define NOTE_DS8 4978

\#define REST 0

int tempo=114; // change this to make the song slower or faster

int buzzer = 8;// initializes digital I/O PIN to control the buzzer

// notes of the moledy followed by the duration

// a 4 means a quarter note, 8 an eighteenth , 16 sixteenth, so on

// !!negative numbers are used to represent dotted notes

// so -4 means a dotted quarter note, a quarter plus an eighteenth

int melody[] = {

NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//1

NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4,

NOTE_E4,-4, NOTE_D4,8, NOTE_D4,2,

NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//4

NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4,

NOTE_D4,-4, NOTE_C4,8, NOTE_C4,2,

NOTE_D4,4, NOTE_D4,4, NOTE_E4,4, NOTE_C4,4,//8

NOTE_D4,4, NOTE_E4,8, NOTE_F4,8, NOTE_E4,4, NOTE_C4,4,

NOTE_D4,4, NOTE_E4,8, NOTE_F4,8, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_D4,4, NOTE_G3,2,

NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//12

NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4,

NOTE_D4,-4, NOTE_C4,8, NOTE_C4,2

};

// each int value is composed of two bytes (16

bits)

// there are two values per note , so for each note there

are four bytes

int notes=sizeof(melody)/sizeof(melody[0])/2;

// this calculates the duration of a whole note in ms(60s/tempo)x4 beats

int wholenote = (60000 x 4) / tempo;

int divider = 0, noteDuration = 0;

void setup() {

// iterate over the notes of the melody

// remember, the array is twice the number of notes (notes + durations)

for (int thisNote = 0; thisNote \< notes x 2; thisNote = thisNote + 2) {

// calculates the duration of each note

divider = melody[thisNote + 1];

if (divider \> 0) {

noteDuration = (wholenote) / divider; // regular note, just proceed

} else if (divider \< 0) {

// dotted notes are represented with negative durations!!

noteDuration = (wholenote) / abs(divider);

noteDuration x= 1.5; // increases the duration in half for dotted notes

}

// we only play the note for 90% of the duration, leaving 10% as a pause

tone(buzzer, melody[thisNote], noteDurationx0.9);

// Wait for the specief duration before playing the next note

delay(noteDuration);

noTone(buzzer); // stop the waveform generation before the next note

}

}

void loop() {

// if you want to repeat the song forever,

// just paste the setup code here instead.

}

Result

Upload the project code, wire up and power on, then the passive buzzer will play a song.

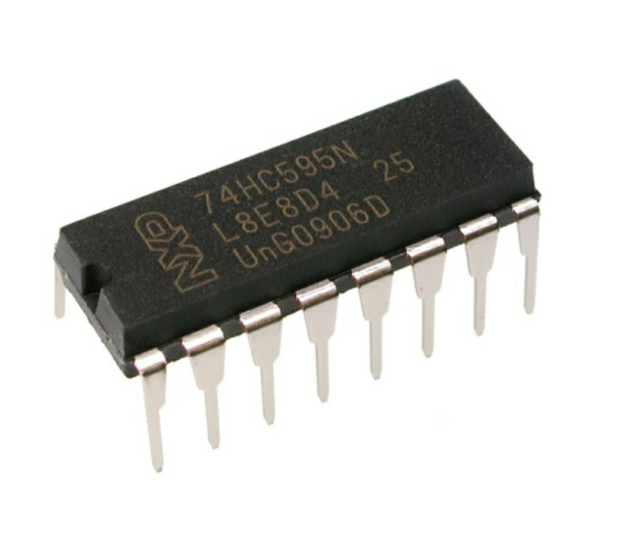

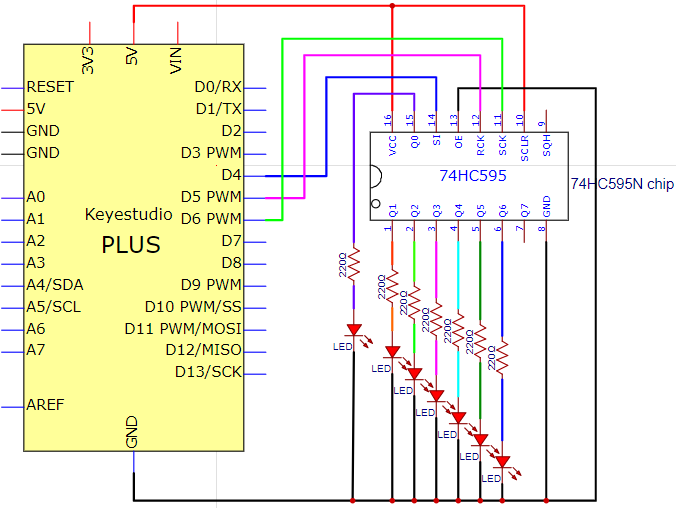

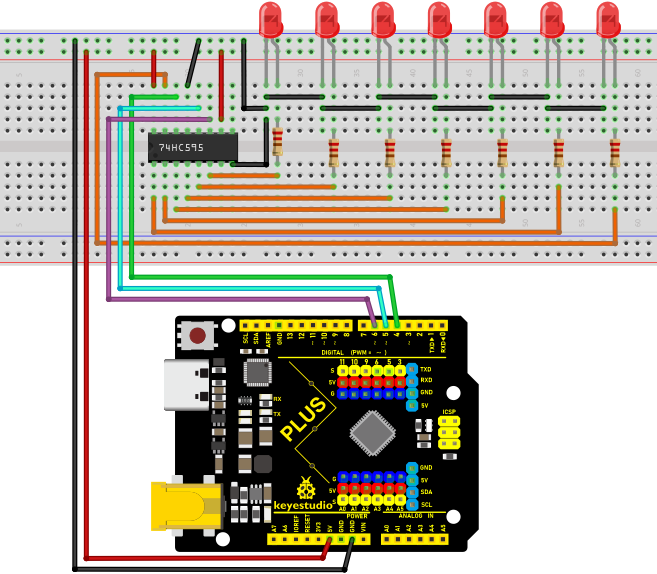

Project 9: 74HC595N Controls 7 LEDs

Introduction

For a PLUS mainboard, it has only 22 I/O ports, how do we light up a large number of LEDs? In this project, we will use 74HC595N to control 7 LEDs to save port resources.

Components Required

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Red LEDx7 |

74HC595N Chipx1 |

220Ω Resistorx7 |

Breadboardx1 |

Jumper Wires |

USB Cablex1 |

Component Knowledge

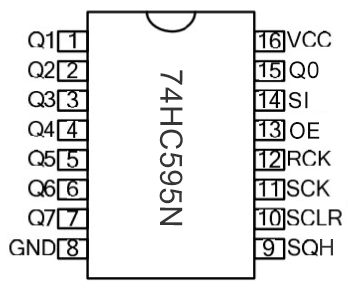

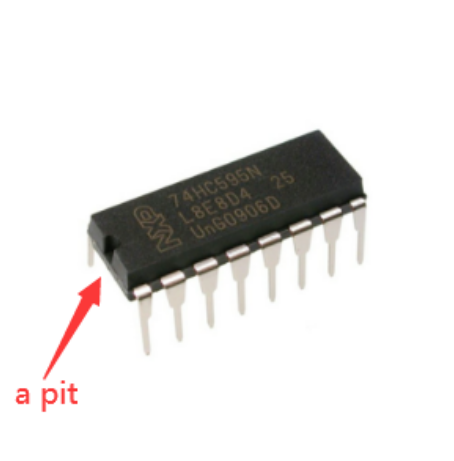

74HC595N Chip: To put it simply, 74HC595N chip is a combination of 8-digit shifting register, memorizer and equipped with tri-state output.The shift register and the memorizer are synchronized to different clocks, and the data is input on the rising edge of the shift register clock SCK and goes into the memory register on the rising edge of the memory register clock RCK. If the two clocks are connected together, the shift register is always one pulse earlier than the storage register.

The shift register has a serial shift input (SI) and a serial output (SQH) for cascading. The 8-bit shift register can be reset asynchronously (low-level reset), and the storage register has an 8-bit Three-state parallel bus output, when the output enable (OE) is enabled (active low), the storage register is output to the 74HC595N pin (bus).

Pins:

Pin13 OE |

It is an output enable pin to ensure that the data of the latch is input to the Q0 to Q7 pins or not. When it is low, no high level is output. In this experiment, we directly connect to GND and keep the data output low. |

|---|---|

Pin14 SI |

This is the pin for 74HC595 to receive data, i.e. serial data input, only one bit can be input at a time, then 8 times in a row, it can form a byte. |

Pin10 SCLR |

A pin to initialize the storage register pins. It initializes the internal storage registers at a low level. In this experiment, we connect VCC to maintain a high level. |

Pin11 SCK |

The clock pin of the shift register. At the rising edge, the data in the shift register is shifted backward as a whole, and new data input is received. |

Pin12 RCK |

The clock input pin of the storage register . At the rising edge, the data is transferred from the shift register to the storage register. At this time, the data is output in parallel from the Q0 to Q7 ports. |

Pin9 SQH |

It is a serial output pin dedicated for chip cascading to the SI terminal of the next 74HC595. |

Q0–Q7(Pin 15,Pin1-7) |

Eight-bit parallel output, can directly control the 8 segments of the digital tube. |

VCC and GND are used used for chip power supply, and the operating voltage is 5V.

Circuit Diagram and Wiring Diagram

Note: Pay attention to the direction in which the 74HC595N chip is inserted.

Code

/*

Keyestudio 2021 Starter Kit

Project 9

74HC595N_control_7_LEDS

http//www.keyestudio.com

*/

int data = 4;// sets PIN 4 of the 74HC595 to datainput PIN SI

int clock = 6;// sets PIN 6 of the 74HC595 to clock PIN SCK

int latch = 5;// sets PIN 5 of the 74HC595 to output latch RCK

int ledState = 0;

const int ON = HIGH;

const int OFF = LOW;

void setup()

{

pinMode(data, OUTPUT);

pinMode(clock, OUTPUT);

pinMode(latch, OUTPUT);

}

void loop()

{

for(int i = 0; i \< 256; i++)

{

updateLEDs(i);

delay(500);

}

}

void updateLEDs(int value)

{

digitalWrite(latch, LOW);//

shiftOut(data, clock, MSBFIRST, \~value);// shift out highbyte

digitalWrite(latch, HIGH);// lock

}

Result

Upload project code, wire up and power on, then you can see the changes of 7 LEDs cyclically.

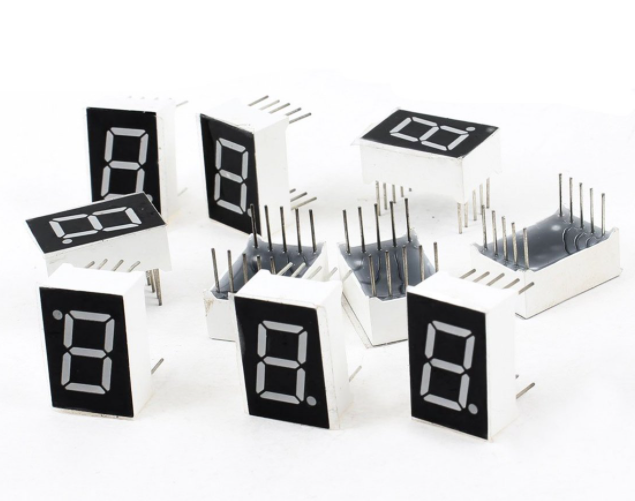

Project 10: 1-Digit Digital Tube

Introduction

The seven-segment digital tube is an electronic display device that displays decimal numbers. It is widely used in digital clocks, electronic meters, basic calculators and other electronic devices that display digital information. The tubes are an alternative to more complex dot-matrix displays that are easy to use in both limited light conditions and strong sunlight. In this project, we will use the PLUS control board to control 1-digit digital tube to display numbers.

Components Required

|

|

|

|

|

|

|---|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

1-digit Digital Tubex1 |

220Ω Resistorx8 |

Breadboardx1 |

Jumper Wires |

USB Cablex1 |

Component Knowledge

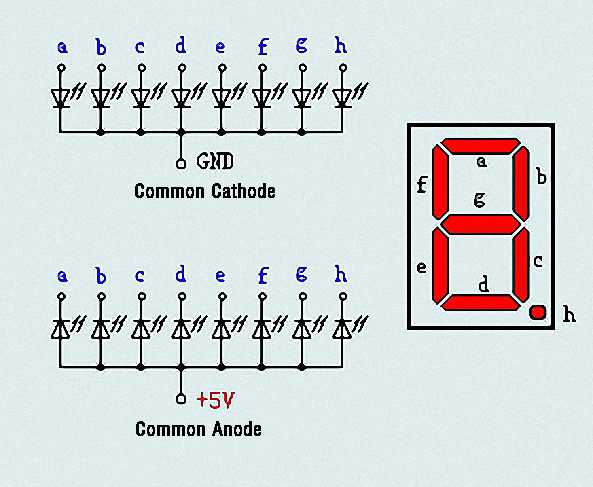

Display principle: the digital tube display is a semiconductor light-emitting device. Its basic unit is a light-emitting diode (LED). The digital tube display can be divided into 7-segment digital tube and 8-segment digital tube according to the number of segments. The 8-segment digital tube has one more LED unit than the 7-segment digital tube (used for decimal point display). Each segment of the 7-segment LED display is a separate LED. According to the connection mode of the LED unit, the digital tube can be divided into a common anode digital tube and a common cathode digital tube.

In the common cathode 7-segment digital tube, all the cathodes (or negative electrodes) of the segmented LEDs are connected together, so you should connect the common cathode to GND. To light up a segmented LED, you can set its associated pin to “HIGH”.

In the common anode 7-segment digital tube, the LED anodes (positive electrodes) of all segments are connected together, so you should connect the common anode to “+5V”. To light up a segmented LED, you can set its associated pin to “LOW”.

Each part of the digital tube is composed of an LED. So when you use it, you also need to use a current limiting resistor. Otherwise, the LED will be damaged. In this experiment, we use an ordinary common cathode one-bit digital tube. As we mentioned above, you should connect the common cathode to GND. To light up a segmented LED, you can set its associated pin to “HIGH”.

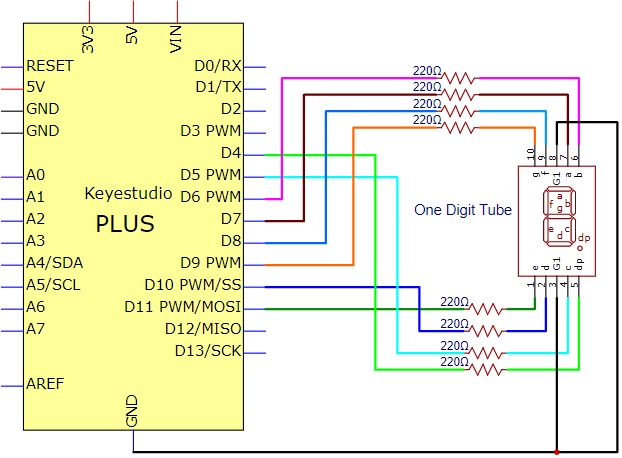

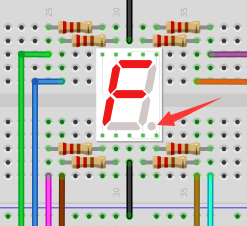

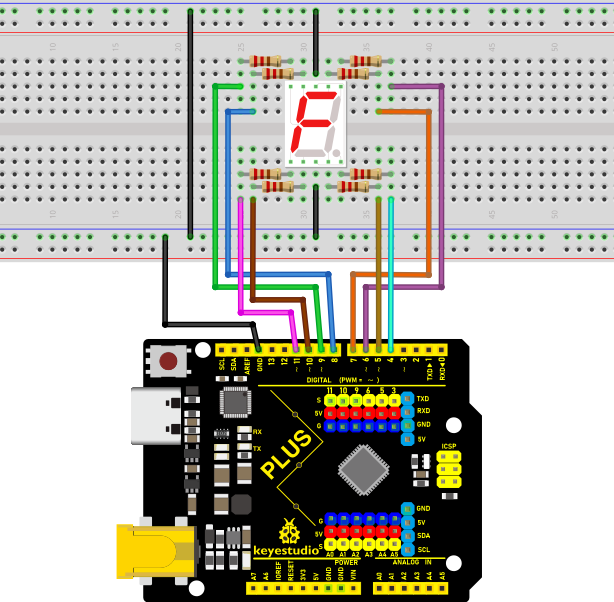

Circuit Diagram and Wiring Diagram

Note: The direction of the 7-segment digital tube inserted into the breadboard is the same as the wiring diagram, and there is one more point in the lower right corner.

Code

The digital display is divided into 7 segments, and the decimal point display is divided into 1 segment. When certain numbers are displayed, the corresponding segment will be illuminated. For example, when the number 1 is displayed, segments b and c will be opened. We compile a subroutine for each number, and compile the main program to display a number every 1 second, and display numbers 9 to 0 in cycles. The display time of each number depends on the delay time, the longer the delay time, the longer the display time.

/*

Keyestudio 2021 Stater Kit

Project 10

1-digit Digital Tube

http//www.keyestudio.com

*/

// sets the IO PIN for every segment

int a=7;// digital PIN 7 for segment a

int b=6;// digital PIN 6 for segment b

int c=5;// digital PIN 5 for segment c

int d=10;//digital PIN 10 for segment d

int e=11;//digital PIN 11 for segment e

int f=8;//digital PIN 8 for segment f

int g=9;//digital PIN 9 for segment g

int dp=4;//digital PIN 4 for segment dp

void digital_0(void) // displays number 0

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e,HIGH);

digitalWrite(f,HIGH);

digitalWrite(g,LOW);

digitalWrite(dp,LOW);

}

void digital_1(void) // displays number 1

{

unsigned char j;

digitalWrite(c,HIGH);// led sets level for PIN 5 to "high",turn on segment c

digitalWrite(b,HIGH);// turns on segment b

for(j=7;j\<=11;j++)// turns off other segments

digitalWrite(j,LOW);

digitalWrite(dp,LOW);// turns off segment dp

}

void digital_2(void) // displays number 2

{

unsigned char j;

digitalWrite(b,HIGH);

digitalWrite(a,HIGH);

for(j=9;j\<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

digitalWrite(c,LOW);

digitalWrite(f,LOW);

}

void digital_3(void) // displays number 3

{digitalWrite(g,HIGH);

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(dp,LOW);

digitalWrite(f,LOW);

digitalWrite(e,LOW);

}

void digital_4(void) // displays number 4

{digitalWrite(c,HIGH);

digitalWrite(b,HIGH);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

digitalWrite(a,LOW);

digitalWrite(e,LOW);

digitalWrite(d,LOW);

}

void digital_5(void) // displays number 5

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b, LOW);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e, LOW);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

}

void digital_6(void) // displays number 6

{

unsigned char j;

for(j=7;j\<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(c,HIGH);

digitalWrite(dp,LOW);

digitalWrite(b,LOW);

}

void digital_7(void) // displays number 7

{

unsigned char j;

for(j=5;j\<=7;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

for(j=8;j\<=11;j++)

digitalWrite(j,LOW);

}

void digital_8(void) // displays number 8

{

unsigned char j;

for(j=5;j\<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

}

void digital_9(void) // displays number 9

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e, LOW);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

}

void setup()

{

int i;// declares a Variable

for(i=4;i\<=11;i++)

pinMode(i,OUTPUT);// sets PIN 4-11 to "output"

}

void loop()

{

while(1)

{

digital_9();// displays number 9

delay(1000); // waits a sencond

digital_8();// displays number 8

delay(1000); // waits a sencond

digital_7();// displays number 7

delay(1000); // waits a sencond

digital_6();// displays number 6

delay(1000); // waits a sencond

digital_5();// displays number 5

delay(1000); // waits a sencond

digital_4();// displays number 4

delay(1000); // waits a sencond

digital_3();// displays number 3

delay(1000); // waits a sencond

digital_2();// displays number 2

delay(1000); // waits a sencond

digital_1();// displays number 1

delay(1000);// waits a sencond

digital_0();// displays number 0

delay(1000);// waits a sencond

}}

Result

After burning the project code, connecting the wires and powering on, 1-digit digital tube will display numbers from 9 to 0.

Project 11: 4-Digit 7-Segment Tube Display

Introduction:

The 4-digit tube display is low-cost and widely applied to electronic clocks, counters, countdown displays and so on. In this project, we will make the 4-digit 7-segment display show numbers from 0000-9999 through the PLUS MainBoard.

Components:

|

|

|

|

|

|

|---|---|---|---|---|---|

Keyestudio PLUS MainBoardx1 |

Four digit tubex1 |

220ΩResistorx8 |

Jumper Wires |

Breadboardx1 |

USB Cablex1 |

Component Knowledge:

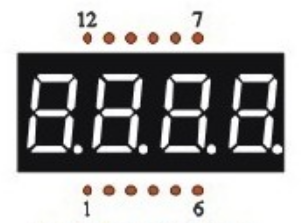

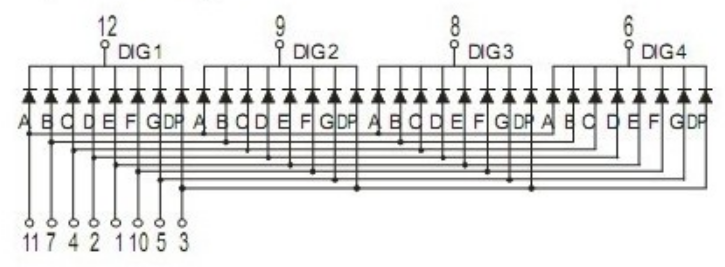

4-digit tube display:

The 4-digit tube display is divided into the anode and cathode . Its working principle is similar to the 7-segment displays are really just seven LEDs lined up in a particular pattern. In this case, the number ‘8’ shape we’re all familiar with. Each of the seven LEDs is called a segment because when illuminated the segment forms part of a numerical digit (both Decimal and Hex) to be displayed. An additional 8th LED is sometimes used for indication of a decimal point.

Our four - digit tubes have common cathodes.

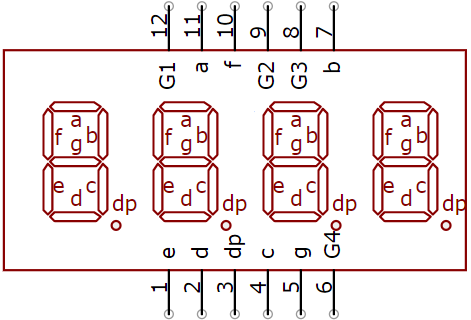

Now have a look at the segment configuration so we know which pins light up which segments. The pinout for the 7-segment display is as follows.

The pin G1, G2, G3 and G4 are pins of the control bit.

The following figure is the schematic diagram of the internal wiring of the 4-bit digital tube:

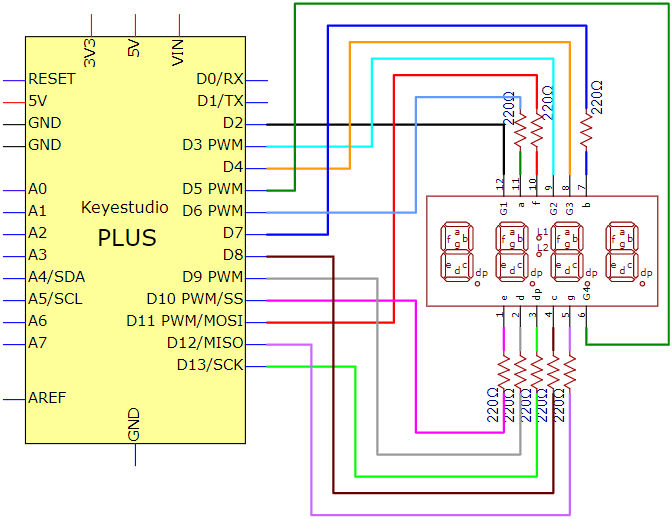

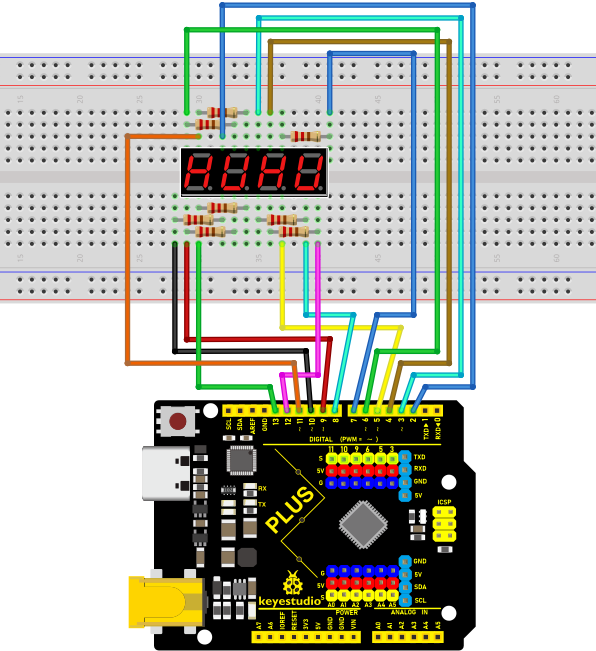

Connection Diagram:

For a four digit tube, limiting resistors are essential and here we use eight resistors of 220Ω。

Test Code:

/*

Keyestudio 2021 starter kit

Project 11

Four_segment_display

http//www.keyestudio.com

*/

int a = 6;

int b = 7;

int c = 8;

int d = 9;

int e = 10;

int f = 11;

int g = 12;

int dp = 13;

int g4 = 5;

int g3 = 4;

int g2 = 3;

int g1 = 2;

// set variables

long n = 1230;

int x = 100;

int del = 55; //

void setup()

{

pinMode(g1, OUTPUT);

pinMode(g2, OUTPUT);

pinMode(g3, OUTPUT);

pinMode(g4, OUTPUT);

pinMode(a, OUTPUT);

pinMode(b, OUTPUT);

pinMode(c, OUTPUT);

pinMode(d, OUTPUT);

pinMode(e, OUTPUT);

pinMode(f, OUTPUT);

pinMode(g, OUTPUT);

pinMode(dp, OUTPUT);

}

/////////////////////////////////////////////////////////////

void loop()

{

int a=0;

int b=0;

int c=0;

int d=0;

unsigned long currentMillis = millis();

while(d\>=0)

{

while(millis()-currentMillis\<10)

{

Display(1,a);

Display(2,b);

Display(3,c);

Display(4,d);

}

currentMillis = millis();

d++;

if (d\>9)

{

c++;

d=0;

}

if (c\>9)

{

b++;

c=0;

}

if (b\>9)

{

a++;

b=0;

}

if (a\>9)

{

a=0;

b=0;

c=0;

d=0;

}

}

}

///////////////////////////////////////////////////////////////

void WeiXuan(unsigned char n)//

{

switch (n)

{

case 1:

digitalWrite(g1, LOW);

digitalWrite(g2, HIGH);

digitalWrite(g3, HIGH);

digitalWrite(g4, HIGH);

break;

case 2:

digitalWrite(g1, HIGH);

digitalWrite(g2, LOW);

digitalWrite(g3, HIGH);

digitalWrite(g4, HIGH);

break;

case 3:

digitalWrite(g1, HIGH);

digitalWrite(g2, HIGH);

digitalWrite(g3, LOW);

digitalWrite(g4, HIGH);

break;

case 4:

digitalWrite(g1, HIGH);

digitalWrite(g2, HIGH);

digitalWrite(g3, HIGH);

digitalWrite(g4, LOW);

break;

default :

digitalWrite(g1, HIGH);

digitalWrite(g2, HIGH);

digitalWrite(g3, HIGH);

digitalWrite(g4, HIGH);

break;

}

}

void Num_0()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void Num_1()

{

digitalWrite(a, LOW);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void Num_2()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, LOW);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, LOW);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_3()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_4()

{

digitalWrite(a, LOW);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_5()

{

digitalWrite(a, HIGH);

digitalWrite(b, LOW);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_6()

{

digitalWrite(a, HIGH);

digitalWrite(b, LOW);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_7()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void Num_8()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_9()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Clear() // clear screens

{

digitalWrite(a, LOW);

digitalWrite(b, LOW);

digitalWrite(c, LOW);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void pickNumber(unsigned char n)// select numbers

{

switch (n)

{

case 0: Num_0();

break;

case 1: Num_1();

break;

case 2: Num_2();

break;

case 3: Num_3();

break;

case 4: Num_4();

break;

case 5: Num_5();

break;

case 6: Num_6();

break;

case 7: Num_7();

break;

case 8: Num_8();

break;

case 9: Num_9();

break;

default: Clear();

break;

}

}

void Display(unsigned char x, unsigned char Number)// Take x as the coordinate

and display numbers

{

WeiXuan(x);

pickNumber(Number);

delay(1);

Clear() ; // clear screens

}

Test Result:

Upload the test code, wire up and power up. The 4-digital tube display shows numbers from 0000-9999.

Project 12:8x8 Dot Matrix Display

Introduction:

8x8 Dot matrix module can be used as display screen, like bus station display, advertising screens and bulletin boards.

On the screen there are 64 circles. And inside each circle has an LED light. There are 64 LEDs, pins on the side, 8 on each. You can see other models like 16x16 Dot matrix, 32x32 Dot matrix.

These 64 LEDs can be lit separately, or lit together. Lighten different LED to show different icons.

The single 8x8 dot matrix comes with 8 LEDs on each row and each cols. There are 16 pins on the side, 8 on each.

Components:

|

|

|

|

|

|

|---|---|---|---|---|---|

Keyestudio PLUS MainBoardx1 |

8x8 Dot Matrix x1 |

220Ω Resistorx8 |

Jumper Wires |

Breadboardx1 |

USB Cablex1 |

Component Knowledge:

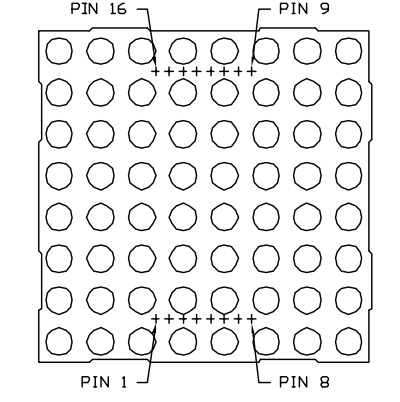

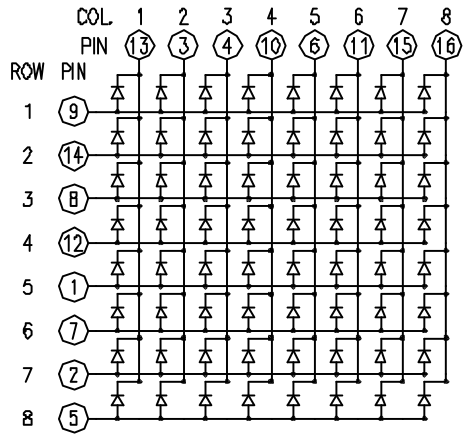

xx8x8 Dot Matrix Display:xxThe 8x8 lattice consists of 64 leds, each LED placed at the intersection of a row and a column. The external view of the lattice screen is shown below.

When the level on a row is 1 and the level on a column is 0 then the corresponding LED will light up.

If you want to light up an LED, for example, you can set the pin 9 to High and pin 13 to Low. If you want to make a row of LEDs light up, you should set the pin 9 to High and set pin ⑬, ③, ④, ⑩, ⑥, ⑪, ⑮ and ⑯ to Low. Equally, turning on a column of LEDs requires to set the pin 13 to Low, and set the pin ⑨, ⑭, ⑧, ⑫, ①, ⑦, ② and ⑤ to High.

The internal view of the dot matrix screen is shown below:

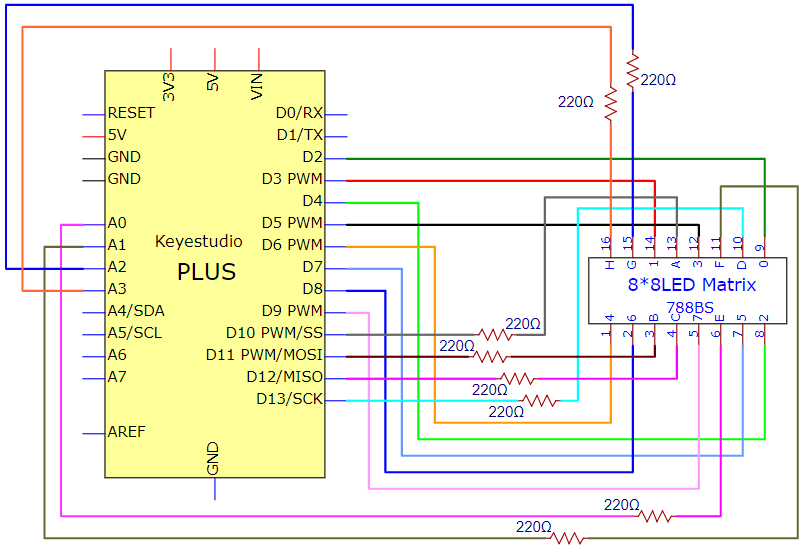

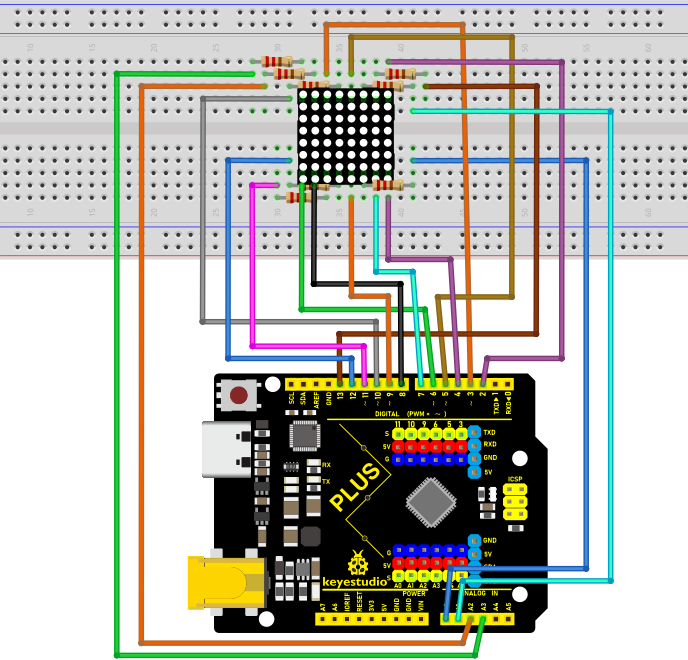

Circuit diagram and wiring diagram:

Note: make the number 788BS on the dot matrix face up

Test Code:

/*

Keyestudio 2021 starter kit

Project 12

12_8_8_Matrix

http//www.keyestudio.com

*/

int R[] = {2,3,4,5,6,7,8,9};

int C[] = {10,11,12,13,A0,A1,A2,A3};

unsigned char data_0[8][8] =

{

{0,0,1,1,1,0,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,0,1,1,1,0,0,0}

};

unsigned char data_1[8][8] =

{

{0,0,0,0,1,0,0,0},

{0,0,0,1,1,0,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,1,1,1,0,0}

};

unsigned char data_2[8][8] =

{

{0,0,1,1,1,0,0,0},

{0,1,0,0,0,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,1,0,0,0,0},

{0,0,1,0,0,0,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,0,0,0}

};

unsigned char data_3[8][8] =

{

{0,0,1,1,1,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,1,1,1,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,1,1,1,1,0,0},

{0,0,0,0,0,0,0,0}

};

unsigned char data_4[8][8] =

{

{0,1,0,0,0,0,0,0},

{0,1,0,0,1,0,0,0},

{0,1,0,0,1,0,0,0},

{0,1,1,1,1,1,1,0},

{0,0,0,0,1,0,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,0,0,0,0,0}

};

unsigned char data_5[8][8] =

{

{0,1,0,0,0,0,0,0},

{0,1,1,1,1,1,0,0},

{0,1,0,0,0,0,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,0,0,0,1,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,0,0,0}

};

unsigned char data_6[8][8] =

{

{0,1,1,1,1,1,0,0},

{0,1,0,0,0,0,0,0},

{0,1,0,0,0,0,0,0},

{0,1,1,1,1,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,0,0,0}

};

unsigned char data_7[8][8] =

{

{0,0,0,0,0,0,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,0,0,1,0,0,0},

{0,0,0,1,0,0,0,0},

{0,0,1,0,0,0,0,0},

{0,1,0,0,0,0,0,0},

{0,0,0,0,0,0,0,0}

};

unsigned char data_8[8][8] =

{

{0,1,1,1,1,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,1,1,1,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,0,0,0}

};

unsigned char data_9[8][8] =

{

{0,1,1,1,1,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,0,0,0,1,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,1,0,0},

{0,0,0,0,0,1,0,0},

{0,1,1,1,1,1,0,0},

{0,0,0,0,0,0,0,0}

};

void Display(unsigned char dat[8][8])

{

for(int c = 0; c\<8;c++)

{

digitalWrite(C[c],LOW);

for(int r = 0;r\<8;r++)

{

digitalWrite(R[r],dat[r][c]);

}

delay(1);

Clear();

}

}

void Clear()

{

for(int i = 0;i\<8;i++)

{

digitalWrite(R[i],LOW);

digitalWrite(C[i],HIGH);

}

}

void setup(){

for(int i = 0;i\<8;i++)

{

pinMode(R[i],OUTPUT);

pinMode(C[i],OUTPUT);

}

}

void loop(){

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_0);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_1);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_2);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_3);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_4);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_5);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_6);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_7);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_8);

}

for (int i = 1; i \<= 100; i = i + (1)) {

Display(data_9);

}

}

Test Result:

Upload the code, connect the wiring diagram and power up. Then 8x8 dot matrix will show numbers from 0 to 9.

Project 13: A Desk Lamp

Introduction

Did you know that Arduino can light up an LED when you press a button? In this project, we will use the Plus Mainboard, a key switch and an LED to make a small desk lamp.

Components Required

|

|

|

|

|

|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Buttonx1 |

Red LEDx1 |

10KΩ Resistorx1 |

Button Capx1 |

|

|

|

|

|

Breadboardx1 |

220Ω Resistorx1 |

USB Cablex1 |

Jumper Wires |

Component Knowledge

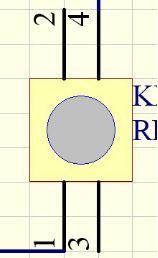

Button: The button can control the circuit on and off. The circuit is disconnected when the button is not pressed. But it breaks when you release it. Why does it only work when you press it? It starts from the internal structure of the button, which is shown in the figure: . Before the button is pressed, 1 and 2 are on, 3 and 4 are also on, but 1, 3 or 1, 4 or 2, 3 or 2, 4 are off (not working). Only when the button is pressed, 1, 3 or 1, 4 or 2, 3 or 2, 4 are on.

. Before the button is pressed, 1 and 2 are on, 3 and 4 are also on, but 1, 3 or 1, 4 or 2, 3 or 2, 4 are off (not working). Only when the button is pressed, 1, 3 or 1, 4 or 2, 3 or 2, 4 are on.

The key switch is one of the most commonly used components in circuit design.

Schematic diagram of the button:

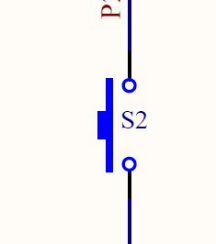

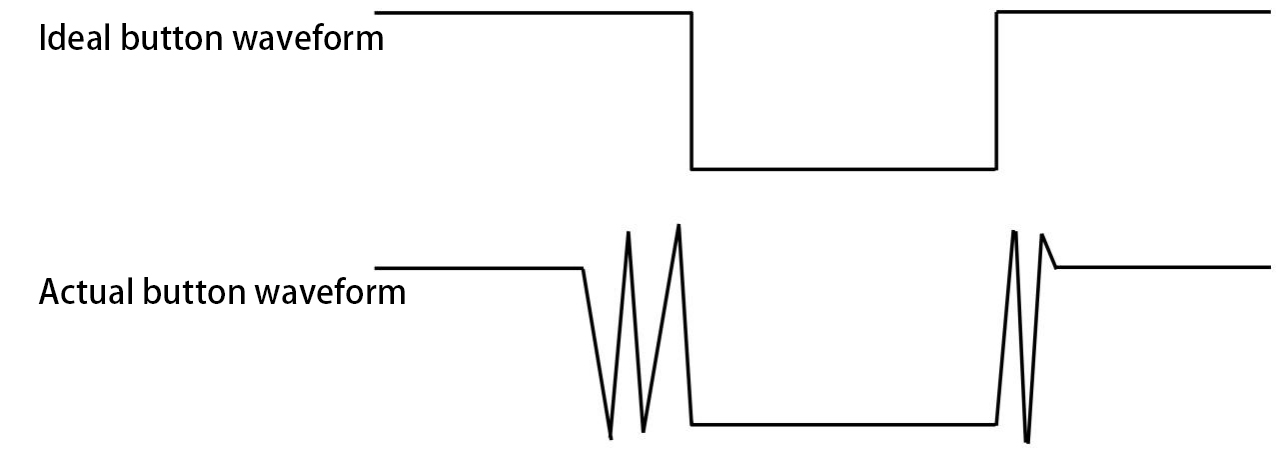

What is button jitter?

We think of the switch circuit as “press the button and turn it on imArduino/mediately”,”press it again and turn it off imArduino/mediately”. In fact, this is not the case.

The button usually uses a mechanical elastic switch, and the mechanical elastic switch will produce a series of jitter due to the elastic action at the moment when the mechanical contact is opened and closed (usually about 10ms). As a result, the button switch will not imArduino/mediately and stably turn on the circuit when it is closed, and it will not be completely and instantaneously disconnected when it is turned off.

How to eliminate the jitter?

There are two common methods, namely fix jitter in the software and hardware. We only discuss the jitter removal in the software.

We already know that the jitter time generated by elasticity is about 10ms, and the delay command can be used to delay the execution time of the command to achieve the effect of jitter removal.

Therefore, we delay 0.05s in the code to achieve the key anti-shake function.

Circuit Diagram and Wiring Diagram

Note:

How to connect the LED

How to identify the 220Ω 5-band resistor and 10KΩ 5-band resistor

Code

/*

Keyestudio 2021 starter learning kit

Project 13

Small_Desk_Lamp

http//www.keyestudio.com

*/

int buttonPin = 5; //the button is connected to 5

int ledPin = 12; // LED is interfaced with 12

int ledState = LOW; // ledState records the state of the LED

int buttonState; // buttonState records the state of the button

int lastButtonState = LOW; // lastbuttonState the state that the button is

pressed before

long lastDebounceTime = 0;

long debounceDelay = 50;

void setup() {

pinMode(buttonPin, INPUT);

pinMode(ledPin, OUTPUT);

digitalWrite(ledPin, ledState);

}

void loop() {

//reading is used to save the data of the buttonPin

int reading = digitalRead(buttonPin);

//record the current timee once the data changes

if (reading != lastButtonState) {

lastDebounceTime= millis();

}

// wait for 50ms and determine again to make sure whether the state is as same as the state of the button

// if not, change the state of the button

// at same time, if the state of the button is high(pressed)then change the

state of the led

if ((millis() - lastDebounceTime) \>debounceDelay) {

if (reading != buttonState) {

buttonState = reading;

if (buttonState == HIGH) {

ledState= !ledState;

}

}

}

digitalWrite(ledPin, ledState);

// chnage the previous state value of the button

lastButtonState = reading;

}

Result

Burn the project code, connect the wires and power on first. Then press the button, the LED will turn on. Press the button again, the LED will turn off.

Project 14: Electronic Hourglass

Introduction

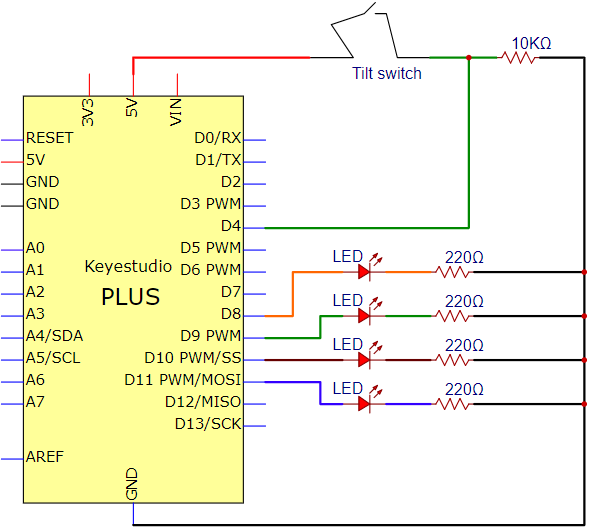

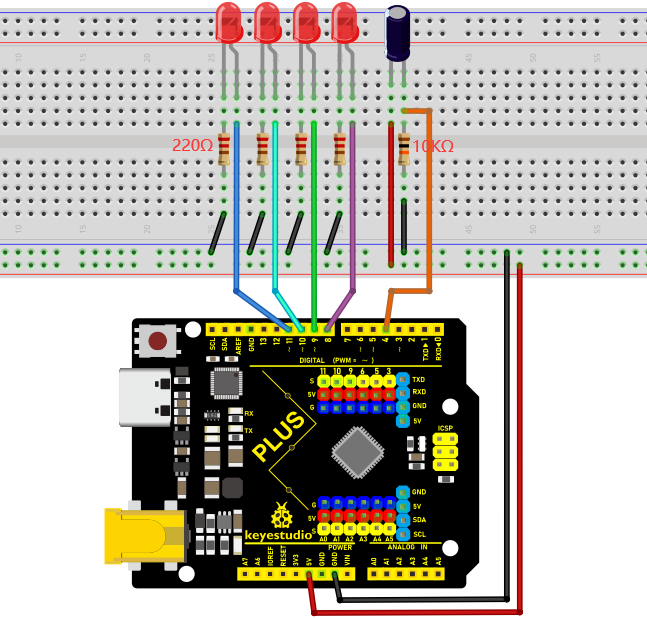

In this lesson, we will use a PLUS mainboard , a tilt switch and 4 LEDs to make an electronic hourglass.

Components Required

|

|

|

|

|---|---|---|---|

Keyestudio Plus Mainboardx1 |

Tilt Switchx1 |

Red LEDx4 |

10KΩ Resistorx1 |

|

|

|

|

Breadboardx1 |

220Ω Resistorx4 |

USB Cablex1 |

Jumper Wires |

Component Knowledge

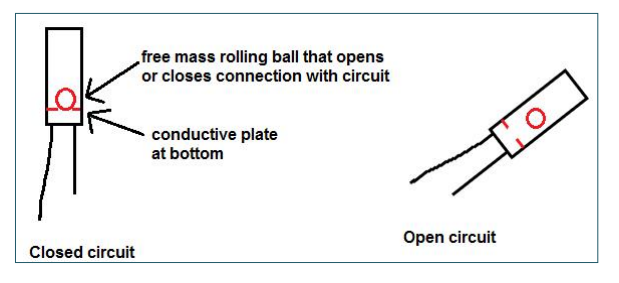

Tilt switch is also called digital switch. Inside is a metal ball that can roll. The principle of rolling the metal ball to contact with the conductive plate at the bottom, which is used to control the on and off of the circuit. When it is a rolling ball tilt sensing switch with single directional trigger, the tilt sensor is tilted toward the trigger end (two gold-plated pin ends), the tilt switch is in a closed circuit and the voltage at the analog port is about 5V(binary number is 1023). In this way, the LED will light up.

When the tilt switch is in a horizontal position or tilted to the other end, it is open and the voltage of the analog port is about 0V (binary number is 0), the LED will turn off. In the program, we judge the state of the switch based on whether the voltage value of the analog port is greater than 2.5V (binary number is 512).

As shown in the figure, use the internal structure of the tilt switch to illustrate how it works.

Circuit Diagram and Wiring Diagram

Note:

How to connect the LED

How to identify the 220Ω 5-band resistor and 10KΩ 5-band resistor

Code

/*

Keyestudio 2021 starter learning kit

Project 14

Electronic_Hourglass

http//www.keyestudio.com

*/

const byte SWITCH_PIN = 4; // the tilt switch is connected to 4

byte switch_state = 0;

void setup()

{

for(int i=8;i\<12;i++)

{

pinMode(i, OUTPUT);

}

pinMode(SWITCH_PIN, INPUT);

for(int i=8;i\<12;i++)

{

digitalWrite(i,0);

}

Serial.begin(9600);

}

void loop()

{

switch_state = digitalRead(SWITCH_PIN);

Serial.println(switch_state);

if (switch_state == 0)

{

for(int i=8;i\<12;i++)

{

digitalWrite(i,1);

delay(1000);

}

}

if (switch_state == 1)

{

for(int i=11;i\>7;i--)

{

digitalWrite(i,0);

delay(1000);

}

}

}

Result

Upload project code, wire up and power up, hold the breadboard. When you tilt the breadboard to any angle, the LEDs will light up one by one. When you turn the breadboard to the original angle, the LEDs will turn off one by one.

Project 15: PIR Motion Sensor Controls the Buzzer

Introduction

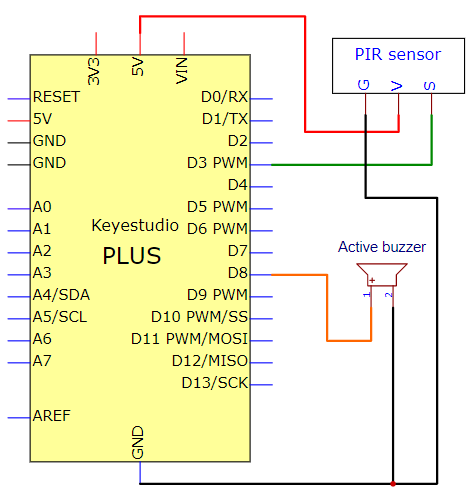

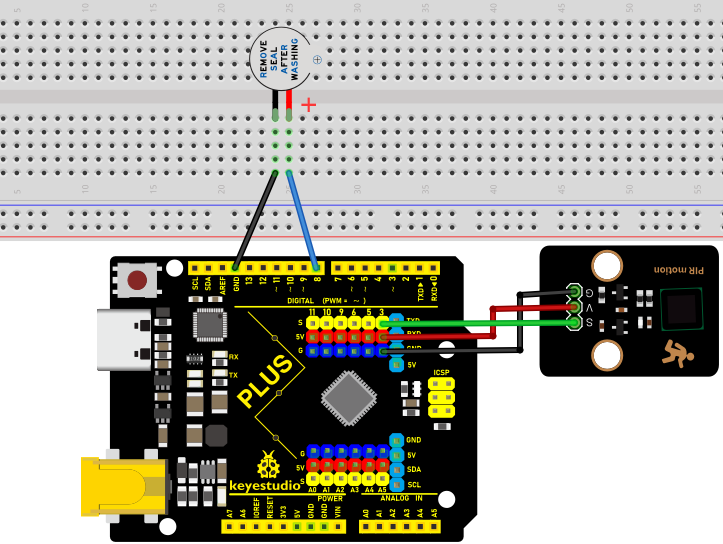

PIR motion sensor measures the thermal infrared (IR) light emitted by moving objects. The sensor can detect the movement of people, animals, and cars to trigger safety alarms and lighting. They are used to detect movement and ideal for security such as burglar alarms and security lighting systems. In this project, we will use a PIR motion sensor and buzzer to detect sounds when people or animals approach.

Components Required

|

|

|

|

|---|---|---|---|

Keyestudio Plus Mainboardx1 |

PIR Motion Sensorx1 |

Active Buzzerx1 |

Breadboardx1 |

|

|

|

|

F-F Dupont Wires |

USB Cablex1 |

Jumper Wires |

Component Knowledge

PIR motion sensor: The principle is that when certain crystals, such as lithium tantalate and triglyceride sulfate, are heated, the two ends of the crystal will generate an equal number of charges with opposite signs. These charges can be converted into voltage output by an amplifier. And the human body will release infrared light, although relatively weak, but still can be detected. When the PIR motion sensor detects the movement of a nearby person, the sensor signal terminal outputs a high level 1. Otherwise, it outputs a low level 0. Pay special attention that this sensor can detect people, animals and cars in motion. People, animals and cars at rest cannot be detected. The maximum detection distance is about 7 meters.

Note: Since vulnerable to radio frequency radiation and temperature changes, the PIR motion sensor should be kept away from heat sources like radiators, heaters and air conditioners, as well as direct irradiation of sunlight, headlights and incandescent light.

Features:

Maximum input voltage: DC 3.3 ~ 5V

Maximum operating current: 50MA

Maximum power: 0.3W

Operating temperature: -20 ~ 85℃

Output high level is 3V, low level is 0V.

Delay time: about 2.3 to 3 seconds

Detection Angle: about 100 degrees

Maximum detection distance: about 7 meters

Indicator light output (when the output is high, it will light up)

Pin limiting current: 50MA

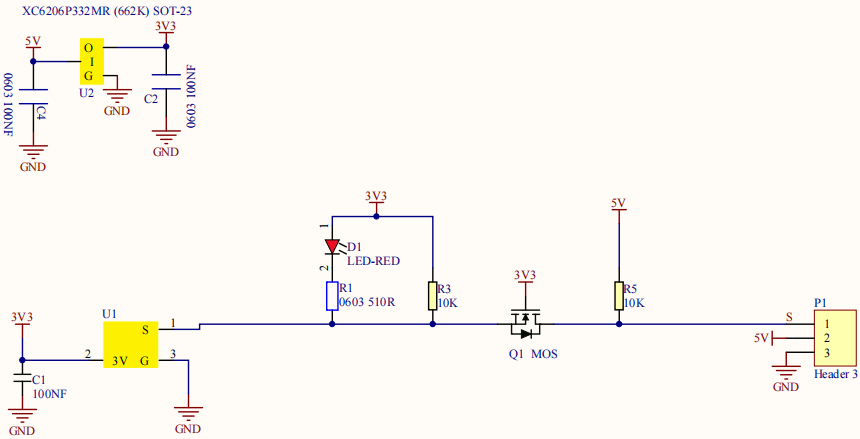

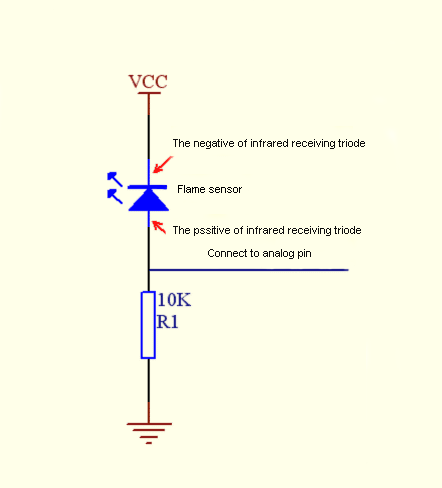

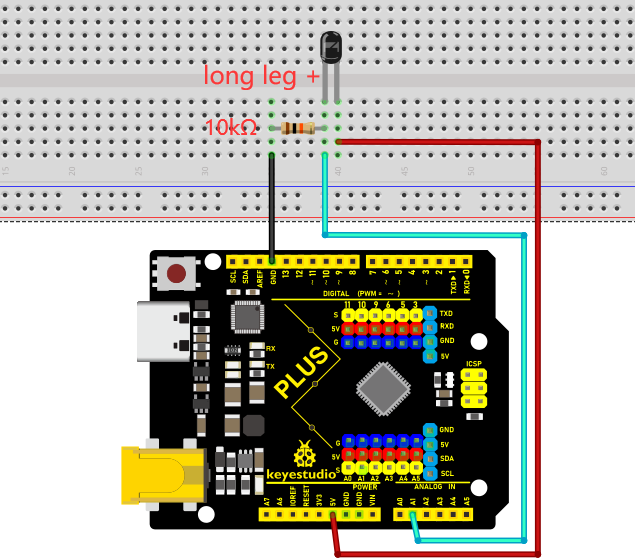

Schematic diagram:

Circuit Diagram and Wiring Diagram

Code

/*

Keyestudio 2021 starter learning kit

Project 15

PIR_control_buzzer

http//www.keyestudio.com

*/

int buzzerpin = 8; // the pin of the buzzer

int pirPin = 3; // the pin of the PIR motion sensor

int pirStat = 0; // the state of the PIR motion sensor

void setup() {

pinMode(buzzerpin, OUTPUT);

pinMode(pirPin, INPUT);

Serial.begin(9600);

}

void loop()

{

pirStat = digitalRead(pirPin);

if (pirStat == HIGH)

{ // if people or moving animals are detected

digitalWrite(buzzerpin, HIGH); // the buzzer chirps

Serial.println("Hey I got you!!!");

}

else {

digitalWrite(buzzerpin, LOW); //if people or moving animals are not detected

turn off buzzers

}

}

Result

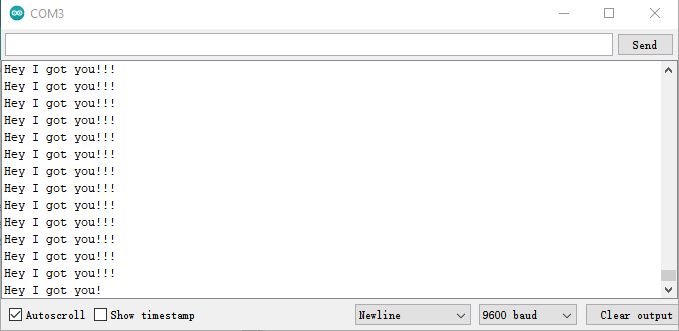

Burn the project code, wire up and power on first. If the PIR motion sensor detects someone nearby, the buzzer will give an alarm. Click to open the serial monitor on the Arduino IDE, and you will see“Hey I got you ! !”.

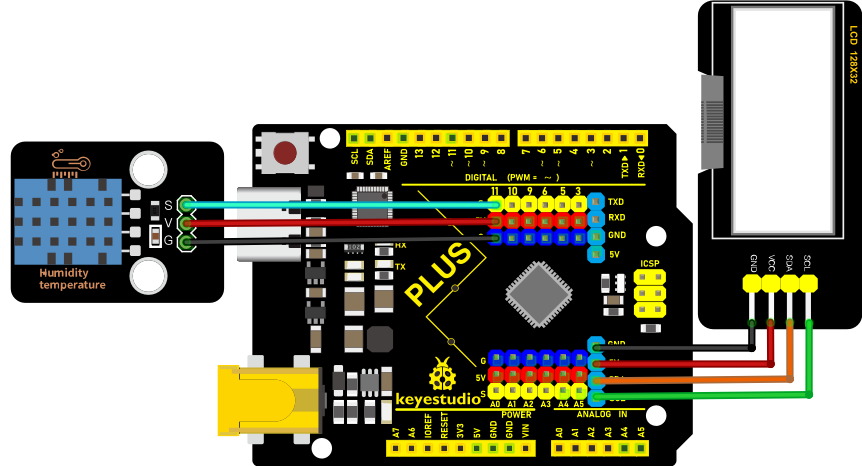

Project 16: I2C LCD_128X32_DOT

Introduction

We can use modules such as monitors to do various experiments in life. You can also DIY a variety of small objects. For example, you can make a temperature meter with a temperature sensor and display, or make a distance meter with an ultrasonic module and display.

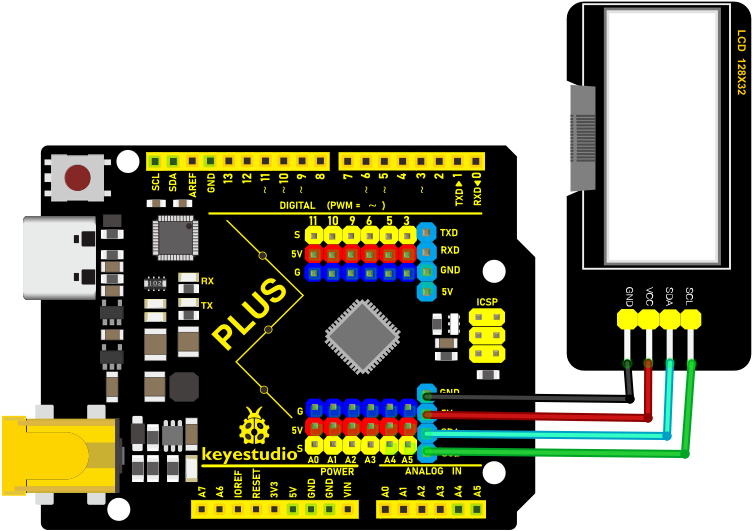

In this project, we will use the LCD_128X32_DOT module as a display and connect it to the Plus control board. The Plus mainboard will be used to control the LCD_128X32_DOT display to show various English characters, common symbols and numbers.

Components Required

|

|

|

|

|---|---|---|---|

Keyestudio Plus Mainboardx1 |

LCD_128X32_DOTx1 |

F-F Dupont Wires |

USB Cablex1 |

Component Knowledge

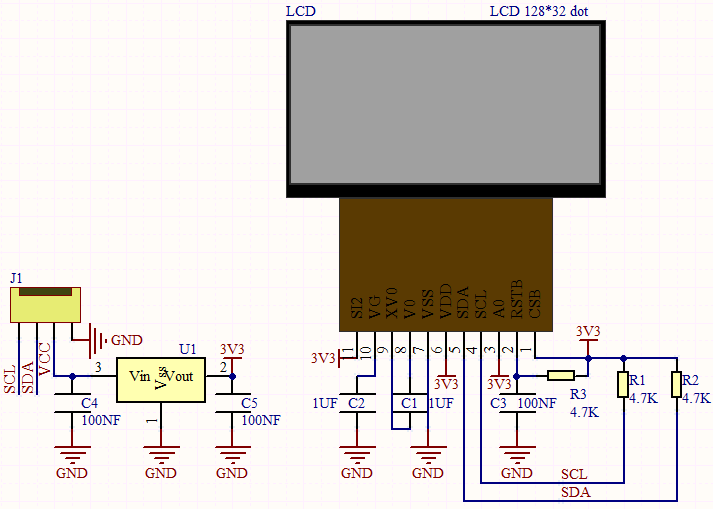

LCD_128X32_DOT: It is an LCD module with 128x32 pixels and its driver chip is ST7567A. The module uses the IIC communication mode, while the code contains a library of all alphabets and common symbols that can be called directly. When using, we can also set it in the code so that the English letters and symbols show different text sizes.

Schematic diagram:

Features:

Pixel:128x32 character

Operating voltage(chip):4.5V to 5.5V

Operating current:100mA (5.0V)

Optimal operating voltage(module):5.0V

Connection Diagram

Code

xxNote:xxThe library file is required in the code. If you have already added the “lcd”library file, you can ignore the process of adding library files.

Put the decompressed “LCD_128X32” folder into “\Arduino\libraries” under the compiler installation directory.

After successful placement, you need to restart the compiler, otherwise the compilation will not work.

e.g.:C:\Program Files\Arduino\libraries

/*

Keyestudio 2021 starter learning kit

Project 16

I2C LCD_128X32_DOT

http//www.keyestudio.com

*/

\#include \<lcd.h\> //add library files

lcd Lcd; //define a Lcd class instance

void setup() {

Lcd.Init(); //initialize

Lcd.Clear(); //clear

}

void loop() {

Lcd.Cursor(0, 4); //Set the first row and the eighth column to display,

Lcd.Display("KEYESTUDIO"); //Display KEYESTUDIO, same as below

Lcd.Cursor(1, 0);

Lcd.Display("ABCDEFGHIJKLMNOPQR");

Lcd.Cursor(2, 0);

Lcd.Display("123456789+-*/\<\>=\$@");

Lcd.Cursor(3, 0);

Lcd.Display("%\^&(){}:;'\|?,.\~\\\\[]");

}

Result

Upload the project code, wire up and power on, the LCD module display will show “KEYESTUDIO” at the first line. “ABCDEFGHIJKLMNOPQR” will be displayed at the second line. “123456789 + - x / <> = $ @ ” will shown at the third line and “% ^ & () {} :; ‘|?,. ~ \ [] ” will be displayed at the fourth line.

Project 17:Small Fan

Introduction:

In this lesson, we will make a small fan with a PLUS MainBoard and a DC motor.

Components:

|

|

|

|

|---|---|---|---|

Keyestudio PLUS MainBoardx1 |

L293D Chipx1 |

DC Motorx1 |

Breadboardx1 |

|

|

|

|

USB Cablex1 |

Jumper Wire |

Fanx1 |

Component Knowledge:

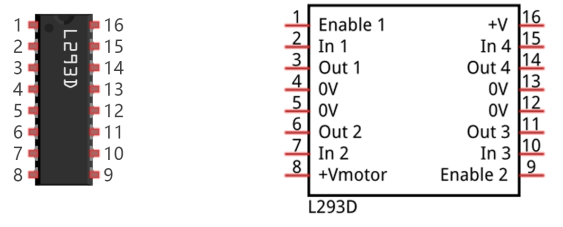

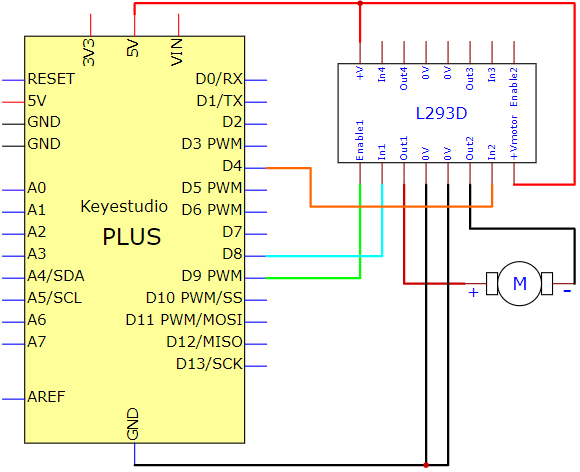

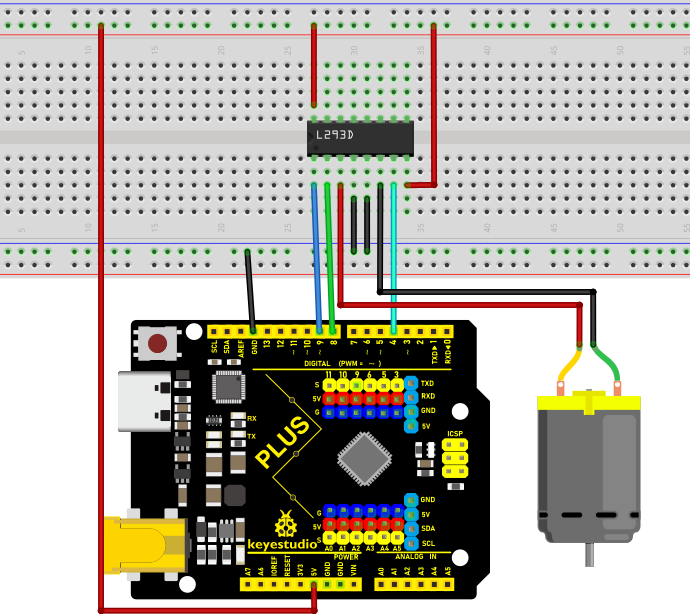

L293D Chip:

L293D is a direct current drive IC, which can be used to drive DC motor or stepper motor in some robot projects.

It has a total of 16 pins and can drive two-channel DC motors at the same time.

Its Input voltage range is 4.5 V ~ 36 V, the output current of per channel is MAX 600mA, which can drive inductive loads. What’s more, its input end can be directly connected and controlled by the single-chip microcomputer.

When driving a small DC motor, the control of two-channel motors and the forward and reverse rotation can be realized by changing the high and low level of the input terminal. There are many motor drive boards using L293D chips on the market, of course, we can also use it via simply connecting.

L293D Pin out:

No |

Name |

Description |

|---|---|---|

1 |

Enable1,2 |

Enable pin Input 1(2)and Input 2(7) |

2 |

Input1 |

Directly input pin 1via digital circuit |

3 |

Output1 |

Connected to one end of motor1 |

4 |

GND |

Grounded(0V) |

5 |

GND |

Grounded(0V) |

6 |

Output2 |

Connected to one end of motor1 |

7 |

Input2 |

Directly output pin 2 via digital circuit |

8 |

Vcc2 (Vss) |

Connected to voltage pin of motor(4.5V-36V) |

9 |

Enable3,4 |

Enable pin 3(10)and 4(15) |

10 |

Input3 |

Input3 pin, controlled by digital circuit |

11 |

Output3 |

Connected to one end of motor2 |

12 |

GND |

Grounded(0V) |

13 |

GND |

Grounded(0V) |

14 |

Output4 |

Connected to one end of motor2 |

15 |

Input4 |

Input4 pin, controlled by digital circuit |

16 |

Vcc1(Vss) |

Connect + 5V to enable IC function |

Circuit diagram and wiring diagram:

Test Code:

/*

Keyestudio 2021 Starter Kit

Project 17

Small_Fan

http//www.keyestudio.com

*/

int IN1=8;

int IN2=4;

int ENA=9;

void setup()

{

pinMode(IN1,OUTPUT);

pinMode(IN2,OUTPUT);

pinMode(ENA,OUTPUT);

}

void loop()

{

//rotate clockwise

digitalWrite(IN1,LOW);

digitalWrite(IN2,HIGH);

analogWrite(ENA,200);

delay(3000);

//delay in 3s

analogWrite(ENA,0);

delay(1000);

//rotate anticlockwise

digitalWrite(IN1,HIGH);

digitalWrite(IN2,LOW);

analogWrite(ENA,100);

delay(3000);

//delay in 3s

analogWrite(ENA,0);

delay(1000);

}

Test Result:

Upload the code to the control board, wire up, install the fan on the motor and power up. Then you can see the fan rotate clockwise for three seconds, stop for one second and anticlockwise for three seconds and stop for one second. Connect ENA to the PWM pin of the plus board, then the speed of the fan can be controlled by the PWM. In the experiment, the clockwise speed is faster than the anticlockwise speed.

Project 18: Servo Rotation

Introduction

Servo is a kind of motor that can rotate very precisely. It has been widely used in toy cars, RC helicopters, airplanes, robots, etc. In this project, we will use the PLUS mainboard to control the rotation of the servo.

Components Required

|

|

|

|---|---|---|

Keyestudio Plus Mainboardx1 |

Servox1 |

USB Cablex1 |

Component Knowledge

Servo:

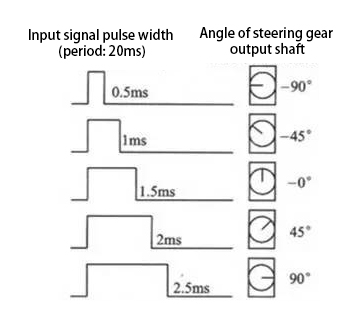

The servo is a kind of position servo driver, which is mainly composed of housing, circuit board, coreless motor, gear and position detector. The working principle is that the receiver or microcontroller sends a signal to the servo, which has an internal reference circuit that generates a reference signal with a period of 20ms and a width of 1.5ms, and compares the DC bias voltage with the voltage of the potentiometer to output voltage difference.

The IC on the circuit board determines the direction of rotation, and then drives the coreless motor to start rotation and transmits the power to the swing arm through the reduction gear, while the position detector sends back a signal to determine whether it has reached the positioning. It is suitable for those control systems that require constant change of angle and can be maintained.

When the motor rotates at a certain speed, the potentiometer is driven by the cascade reduction gear to rotate so that the voltage difference is 0 and the motor stops rotating. The angle range of general servo rotation is 0 to 180 degrees.

The pulse period for controlling the servo is 20ms, the pulse width is 0.5ms to 2.5ms, and the corresponding position is -90° to +90°. The following is an example of a 180 degree servo.

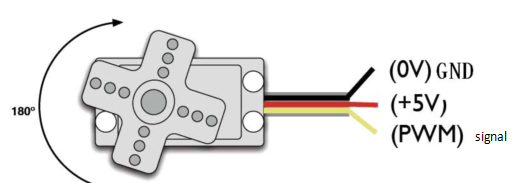

Servo motors have many specifications, but they all have three connecting wires, which are brown, red, and orange (different brands may have different colors). The brown is GND, the red is the positive power supply, and the orange is the signal line.

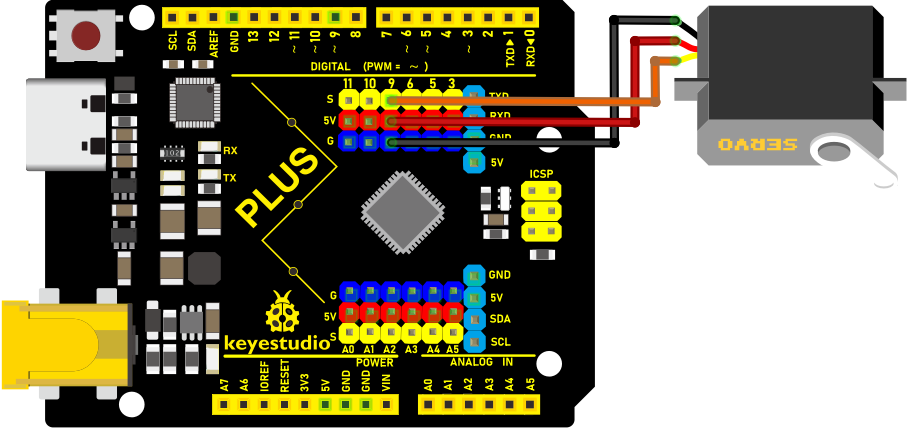

Wiring Diagram

Servo |

Plus mainboard |

|---|---|

Red line |

5V |

Brown line |

G |

Orange line |

9(S) |

Code

xxNote:xxThe library files need to be installed in the code. If you have already added the Servo library files, ignore the process of adding the library files below.

Decompress the library files in the folder, that is, put the decompressed “Servo” folder into “\Arduino\libraries” under the compiler installation directory.

After successful placement, you need to restart the compiler, otherwise the compilation will not work.

e.g.:C:\Program Files\Arduino\libraries

/*

Keyestudio 2021 starter learning kit

Project 18

Servo Rotation

http//www.keyestudio.com

*/

\#include \<Servo.h\>

Servo myservo;// define the name of the servo

void setup()

{

myservo.attach(9);// select the pin of the servo(9)

}

void loop()

{

myservo.write(0);// set the rotation angle of the motor

delay(500);

myservo.write(45);// set the rotation angle of the motor

delay(500);

myservo.write(90);// set the rotation angle of the motor

delay(500);

myservo.write(135);// set the rotation angle of the motor

delay(500);

myservo.write(180);// set the rotation angle of the motor

delay(500);

}

Result

After upload the code to the Plus Mainboard, wire up and power on, the servo will rotate 0°, 45°, 90°, 135°, and 180°.

Project 19: Stepper Motor

Introduction

Stepper motors are accurately positioned and are the most important components in industrial robots, 3D printers, large lathes, and other mechanical devices. In this project, we will use a stepper motor and a clock paper card to make a clock model.

Components Required

|

|

|

|

|

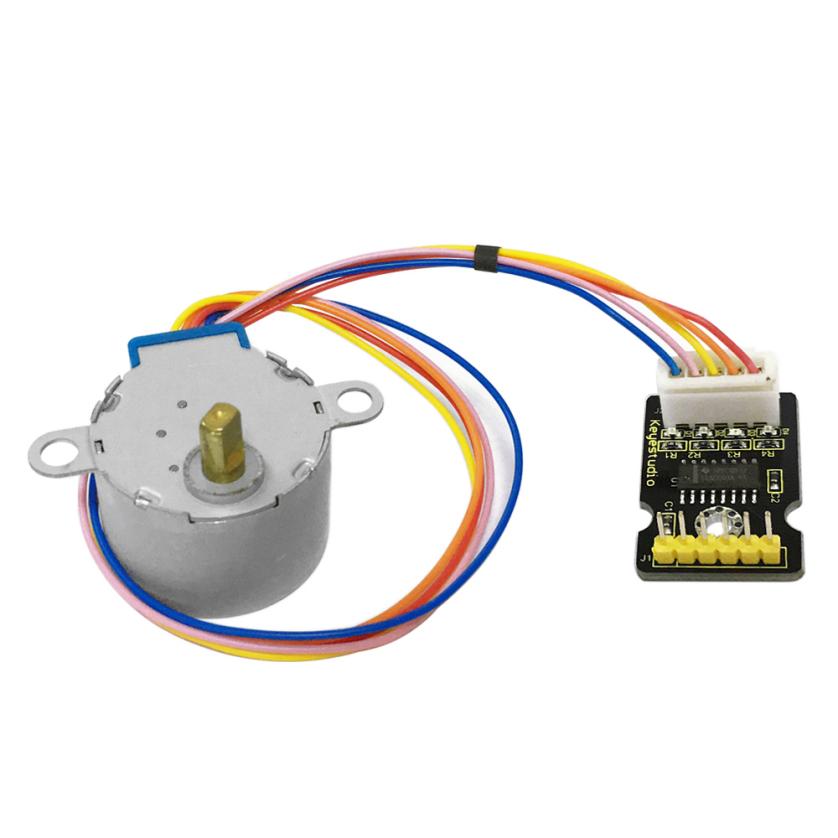

|---|---|---|---|---|

Keyestudio Plus Mainboardx1 |

ULN2003 Stepper Motor Drive Boardx1 |

Stepper Motor x1 |

M-F Dupont Wires |

USB Cablex1 |

Component Knowledge

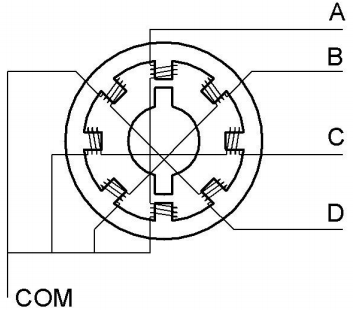

Stepper motor: It is a motor controlled by a series of electromagnetic coils. It can rotate by the exact number of degrees (or steps) needed, allowing you to move it to a precise position and keep it there. It does this by supplying power to the coil inside the motor in a very short time, but you must always supply power to the motor to keep it in the position you want. There are two basic types of stepping motors, namely unipolar stepping motor and bipolar stepping motor. In this project, we use a 28-BYJ48 unipolar stepper motor.

Working Principle:

The stepper motor is mainly composed of a stator and a rotor. The stator is fixed. As shown in the figure below, the part of the coil group A, B, C, and D will generate a magnetic field when the coil group is energized. The rotor is the rotating part. As follows, the middle part of the stator, two poles are permanent magnets.

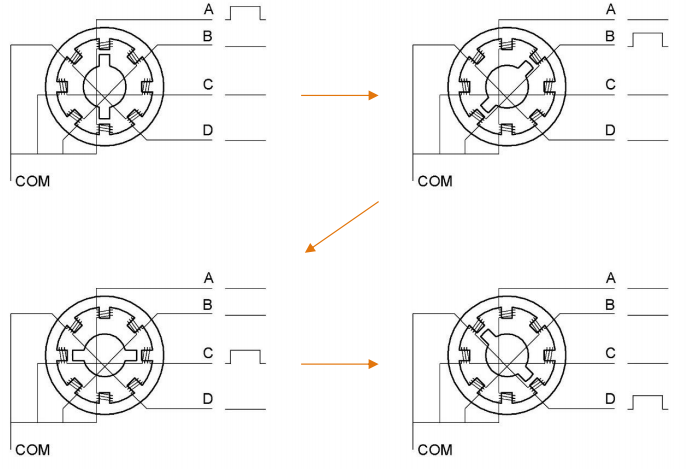

Single -phase four beat: At the beginning, the coils of group A are turned on, and the poles of the rotor point at A coil. Next, the group A coil are disconnected, and the group B coils are turned on. The rotor will turn clockwise to the group B. Then, group B is disconnected, group C is turned on, and the rotor is turned to group C. After that, group C is disconnected, and group D is turned on, and the rotor is turned to group D. Finally, group D is disconnected, group A is turned on, and the rotor is turned to group A coils. Therefore, rotor turns 180° and continuously rotates B-C-D-A, which means it runs a circle (eight phase). As shown below, the rotation principle of stepper motor is A - B - C - D-A.

You make order inverse(D - C - B - A - D …..) if you want to make stepper motor rotate anticlockwise.

Half-phase and eight beat: 8 beat adopts single and dual beat way,A - AB - B - BC - C - CD - D - DA - A …… ,rotor will rotate half phase in this order. For example, when A coil is electrified,rotor faces to A coil then A and B coil are connected, on this condition, the strongest magnetic field produced lies in the central part of AB coil, which means rotating half-phase clockwise.

Stepper Motor Parameters:

The rotor rotates one circle when the stepper motor we provide rotates 32 phases and with the output shaft driven by 1:64 reduction geared set. Therefore the rotation (a circle) of output shaft requires 2048 phases.

The step angle of 4-beat mode of 5V and 4-phase stepper motor is 11.25. And the step angle of 8-beat mode is 5.625, the reduction ratio is 1:64.

ULN2003Stepper Motor Drive Board: It is stepper motor driver.

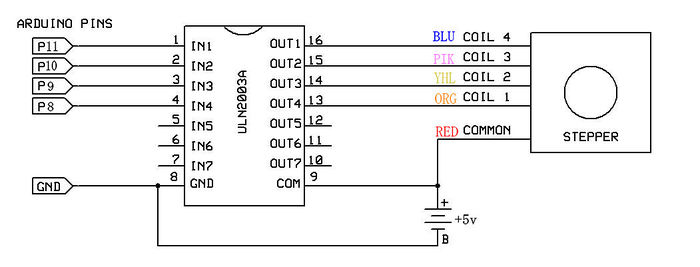

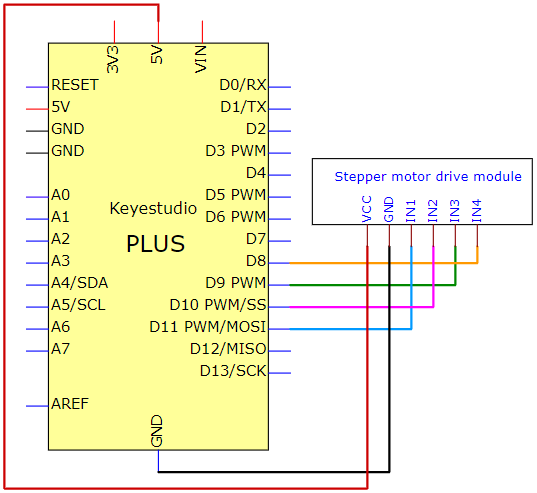

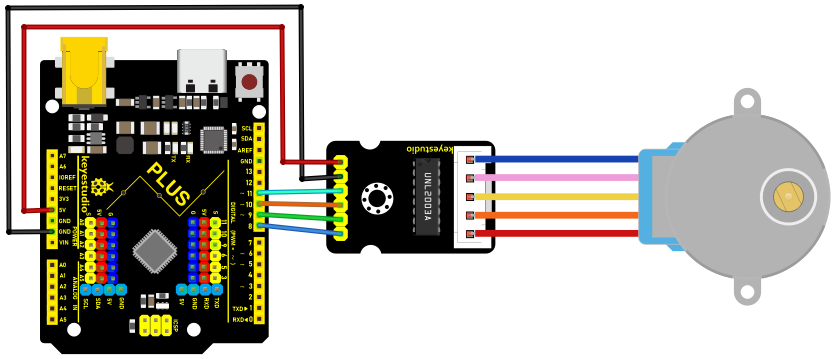

The following schematic diagram shows how to use the ULN2003 stepper motor driver board interface to connect a unipolar stepper motor to the pins of the Plus control board, and shows how to use four TIP120 interfaces.

Schematic Diagram and Wiring Diagram

Code

/*

Keyestudio 2021 starter learning kit

Project 19

Stepper_motor

http//www.keyestudio.com

*/

// pins of the stepper motor

const int IN1_pin = 11;

const int IN2_pin = 10;

const int IN3_pin = 9;

const int IN4_pin = 8;

int val;

void setup() {

Serial.begin(9600);

// the setting of pins of stepper motor in Arduino

pinMode(IN1_pin,OUTPUT);

pinMode(IN2_pin,OUTPUT);

pinMode(IN3_pin,OUTPUT);

pinMode(IN4_pin,OUTPUT);

}

void loop() {

int a = 1024;

int b = 1024;

val=Serial.read();

if(val=='A')

{

while(a--)

{

digitalWrite(IN1_pin, HIGH);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN4_pin, LOW);

delay(10);

digitalWrite(IN1_pin, LOW);

digitalWrite(IN2_pin, HIGH);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN4_pin, LOW);

delay(10);

digitalWrite(IN1_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN3_pin, HIGH);

digitalWrite(IN4_pin, LOW);

delay(10);

digitalWrite(IN1_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN4_pin, HIGH);

delay(10);

}

}

if(val=='C')

{

while(b--)

{

digitalWrite(IN4_pin, HIGH);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, LOW);

delay(10);

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, HIGH);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, LOW);

delay(10);

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, HIGH);

digitalWrite(IN1_pin, LOW);

delay(10);

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, HIGH);

delay(10);

}

}

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, LOW);

}

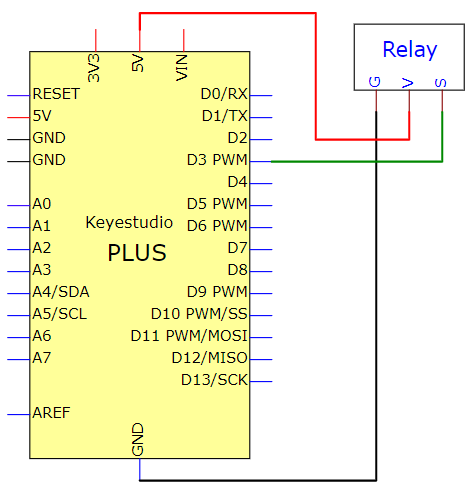

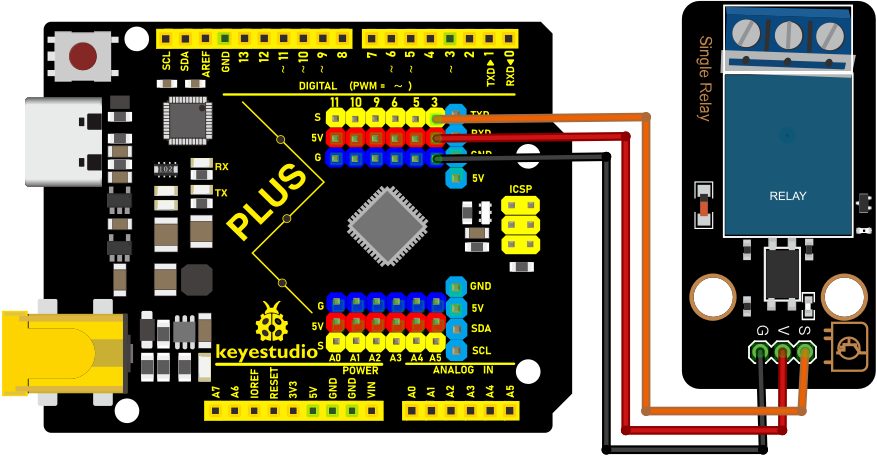

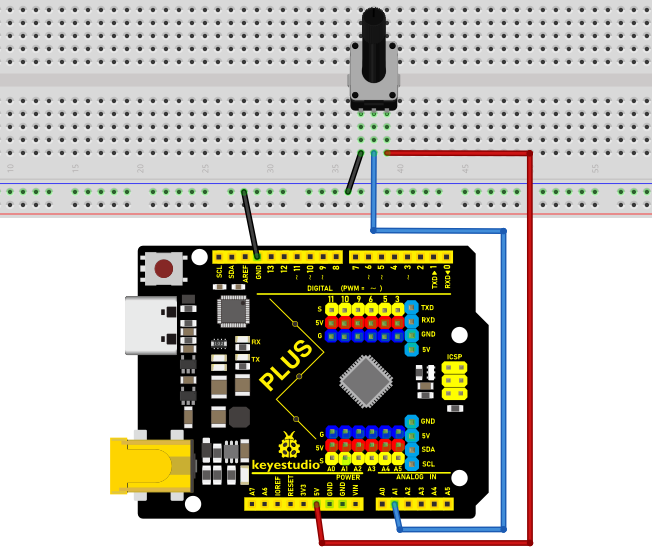

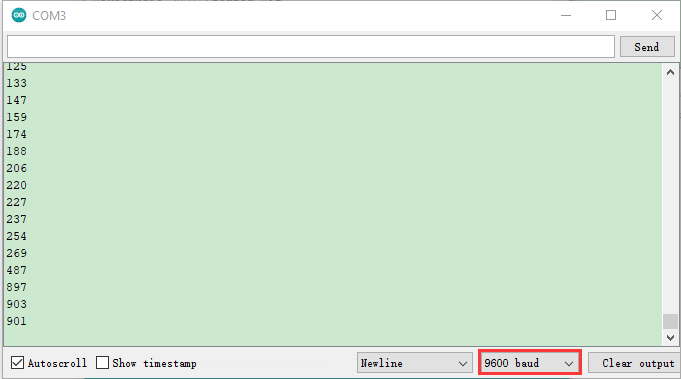

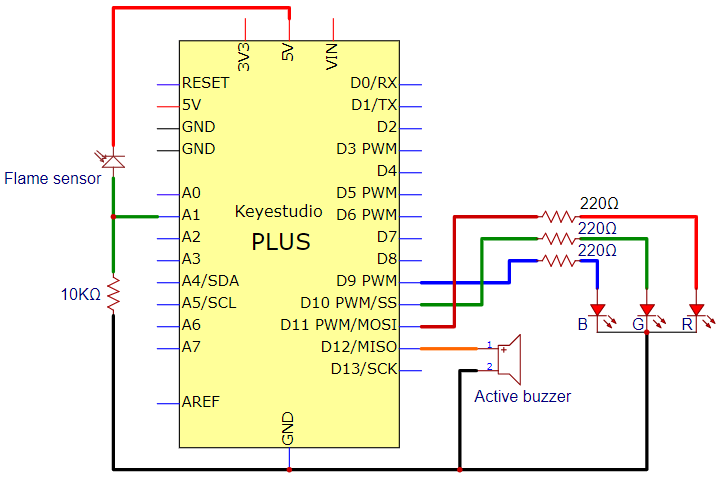

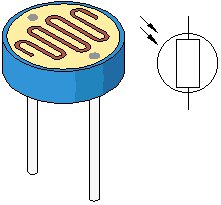

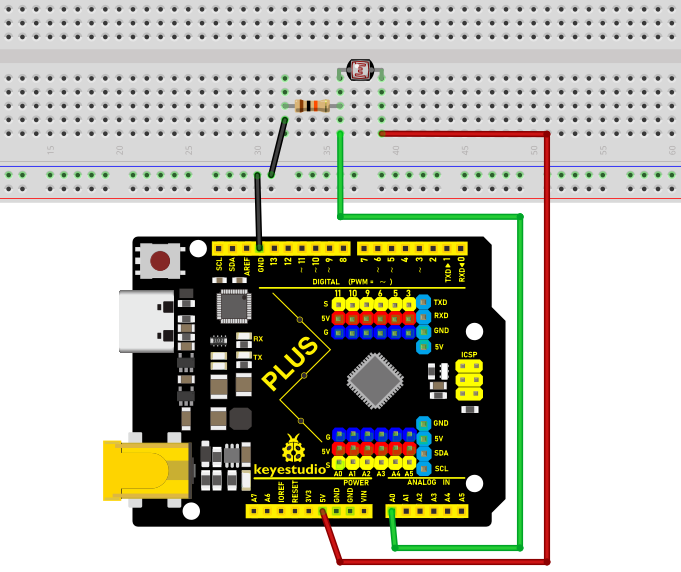

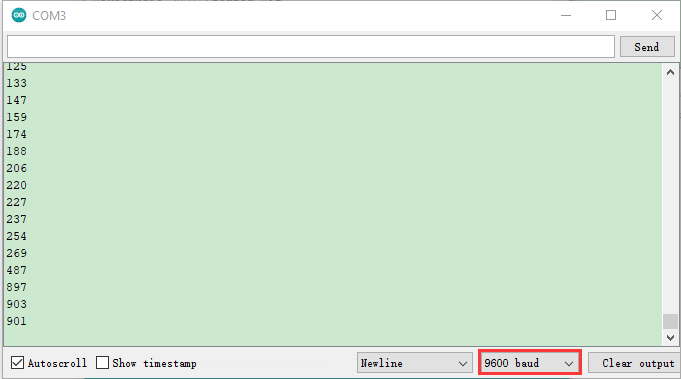

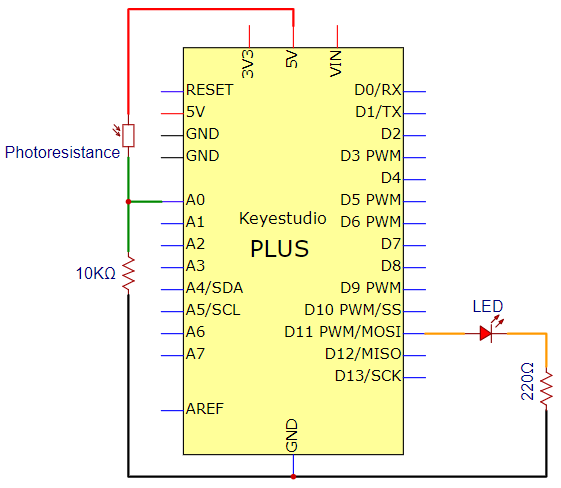

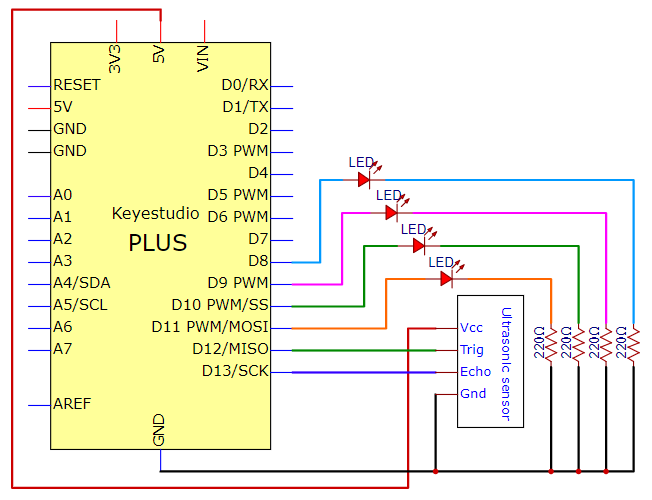

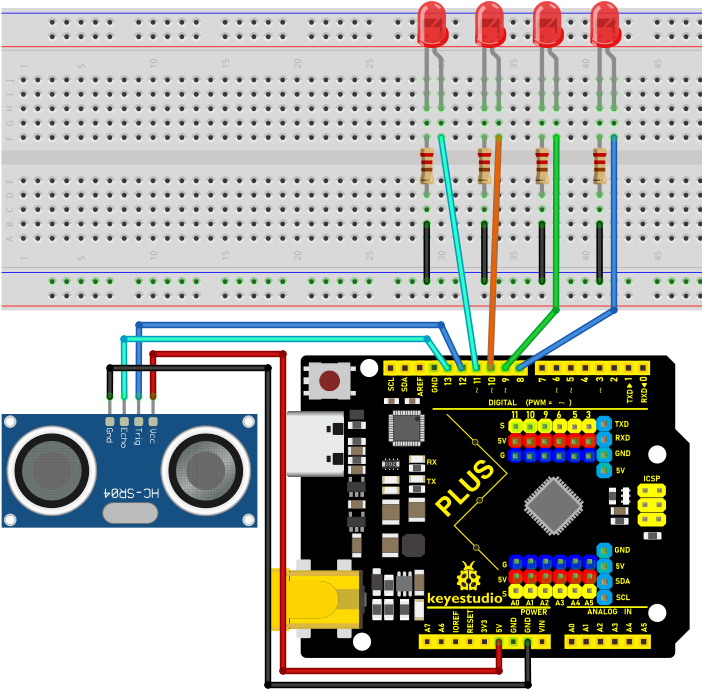

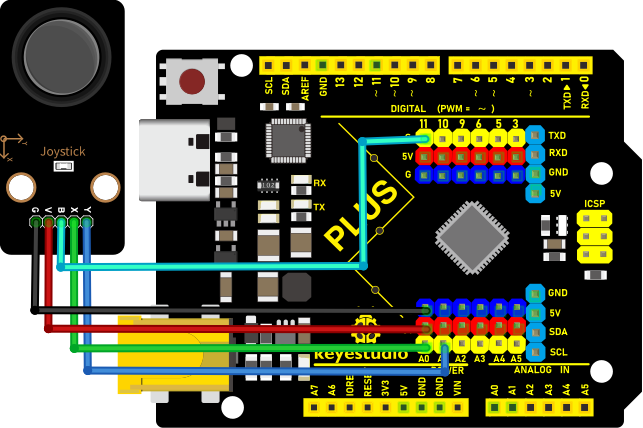

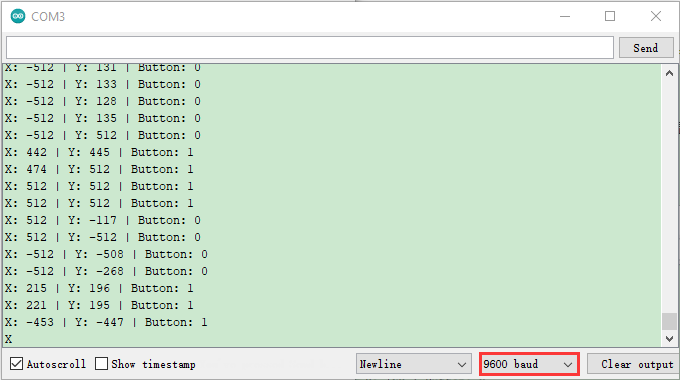

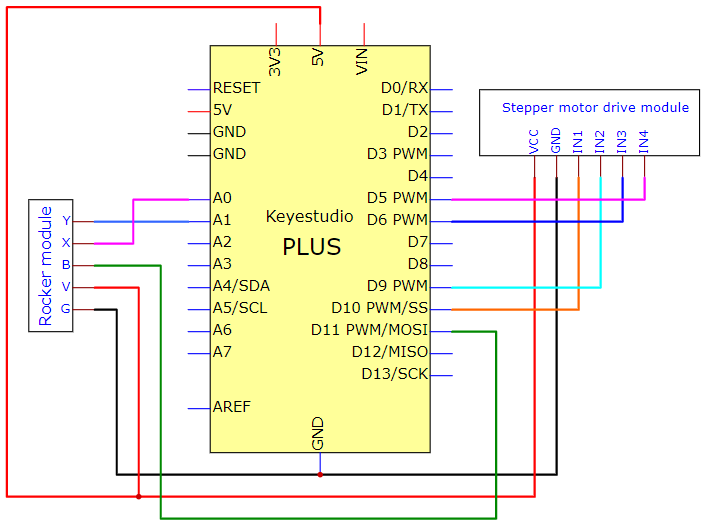

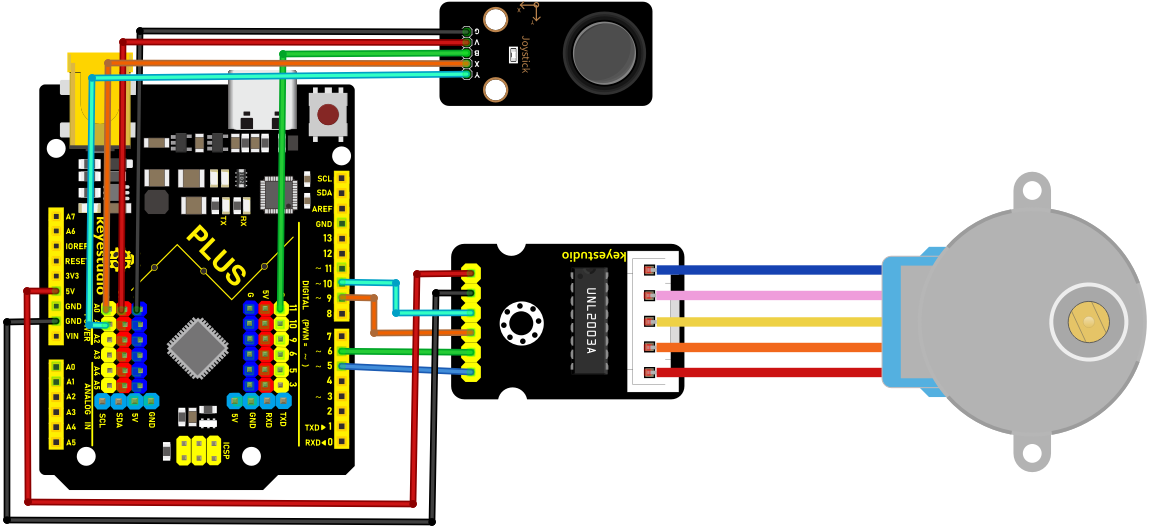

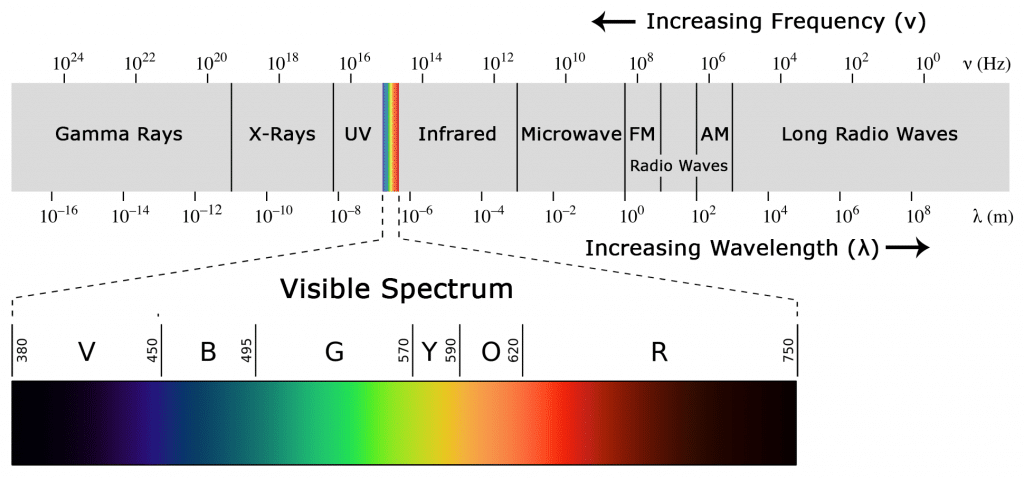

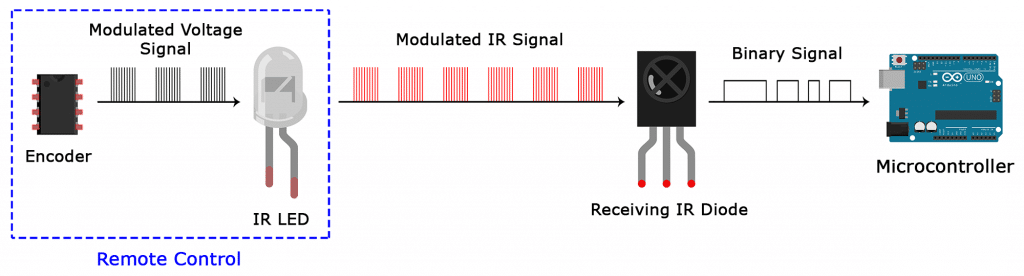

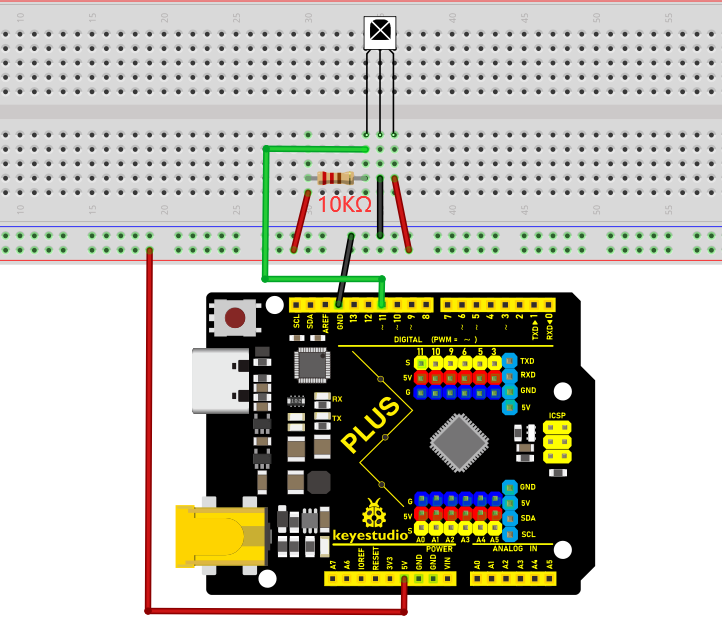

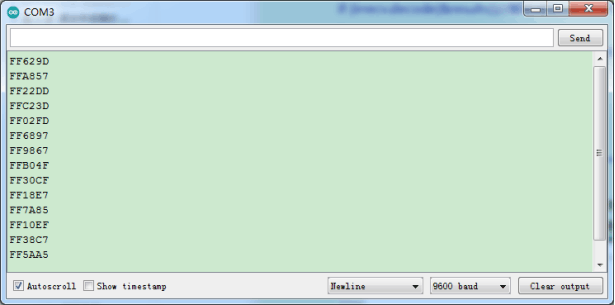

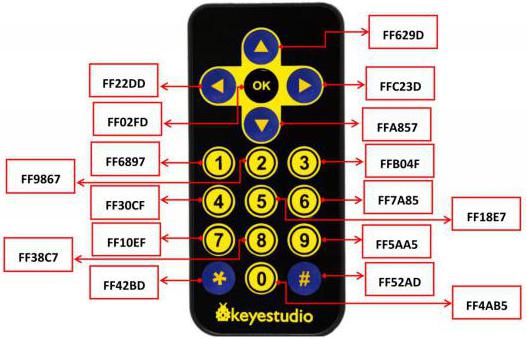

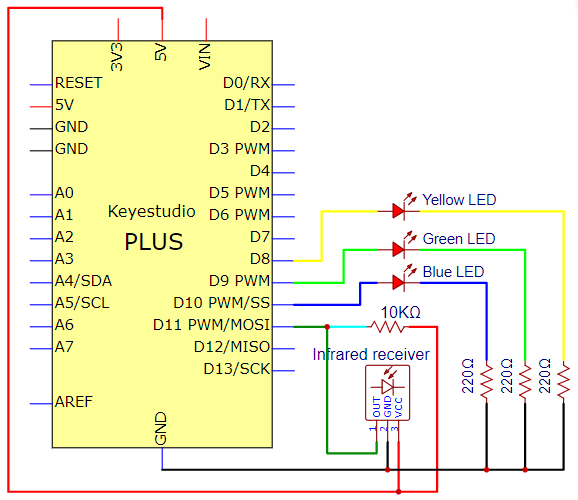

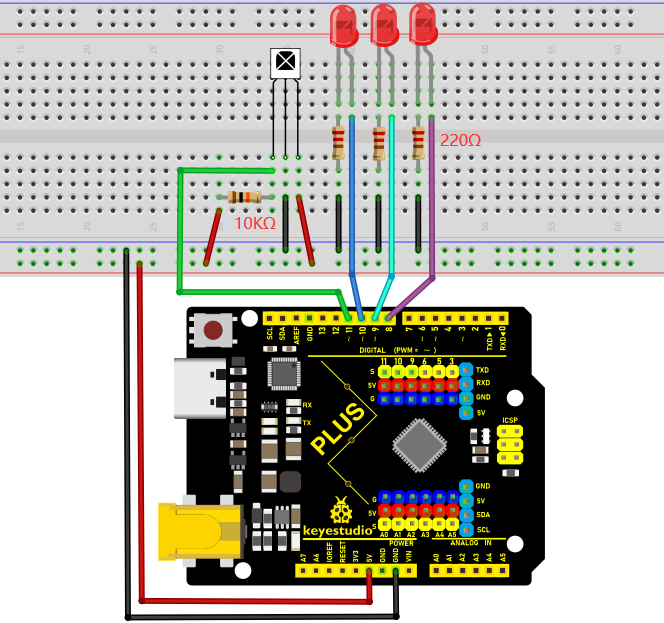

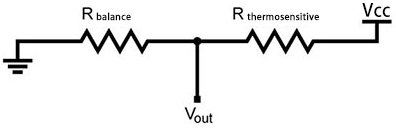

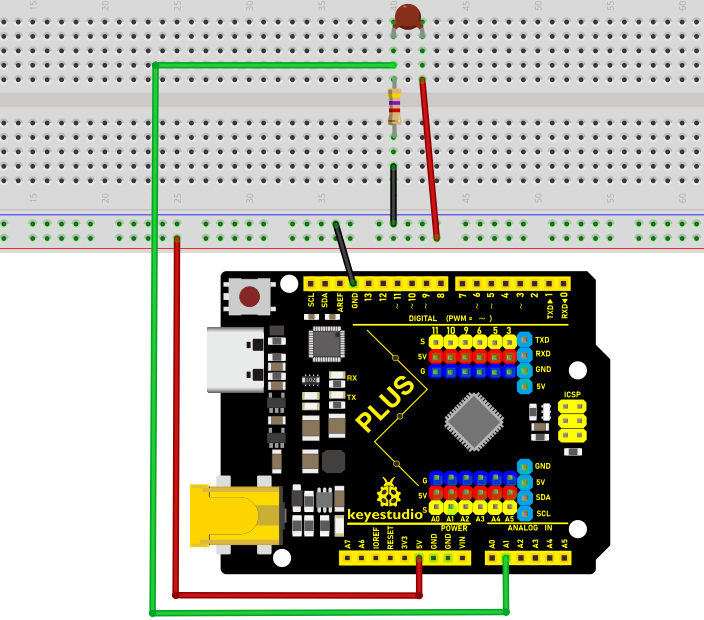

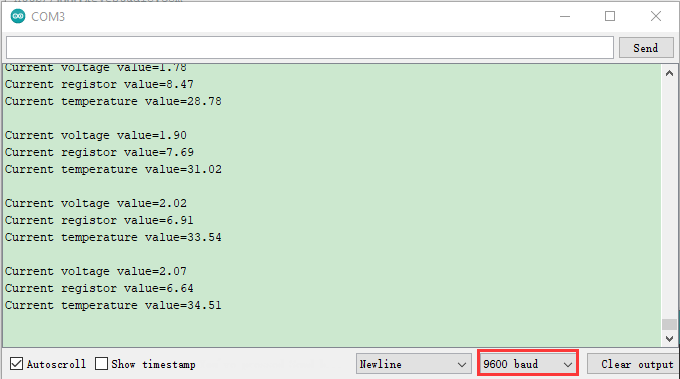

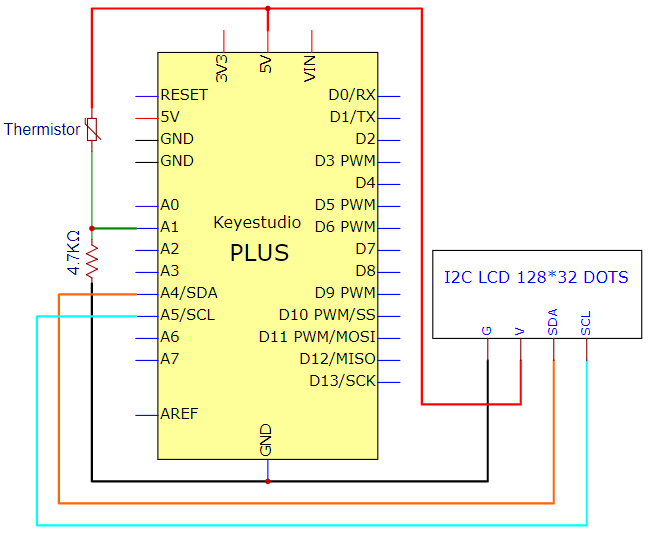

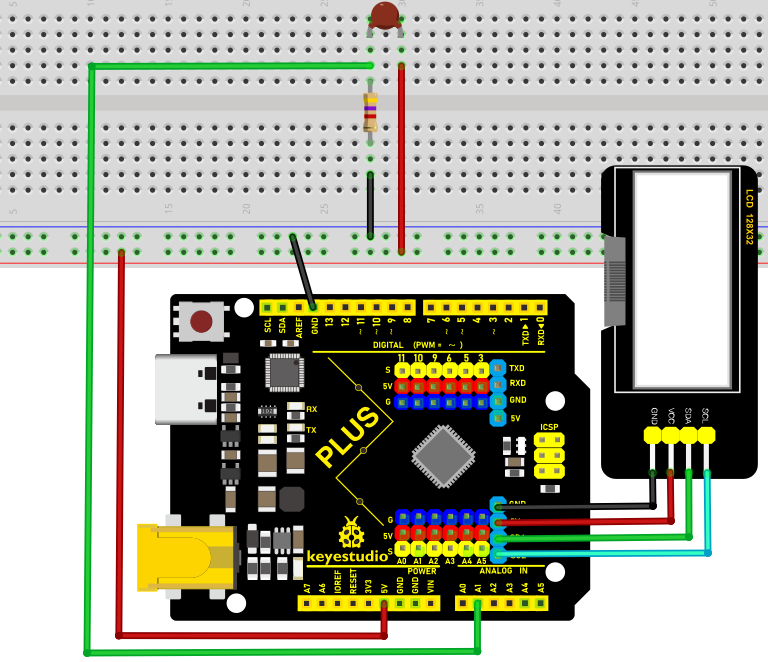

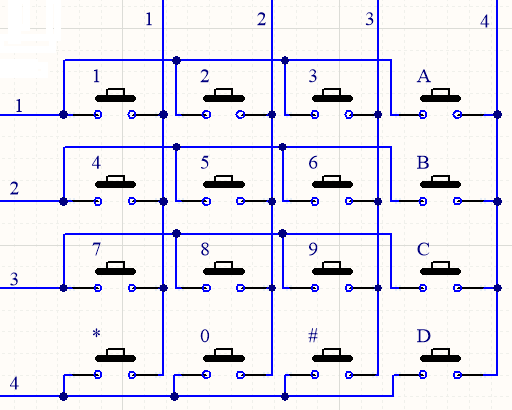

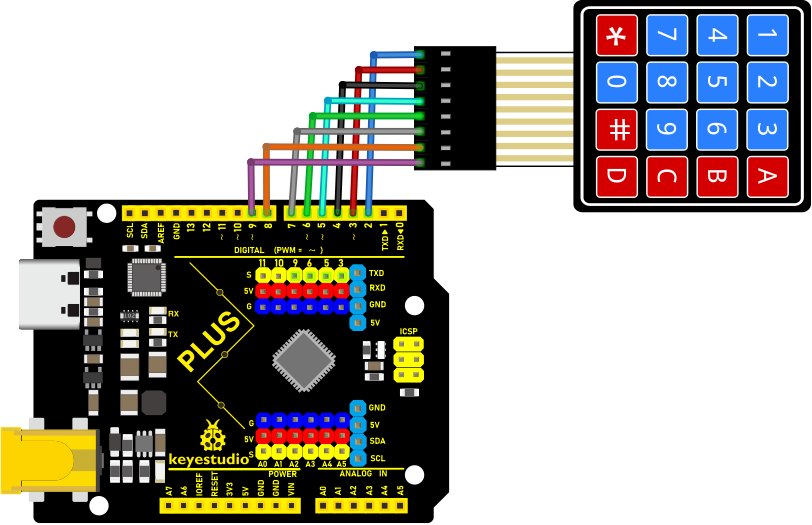

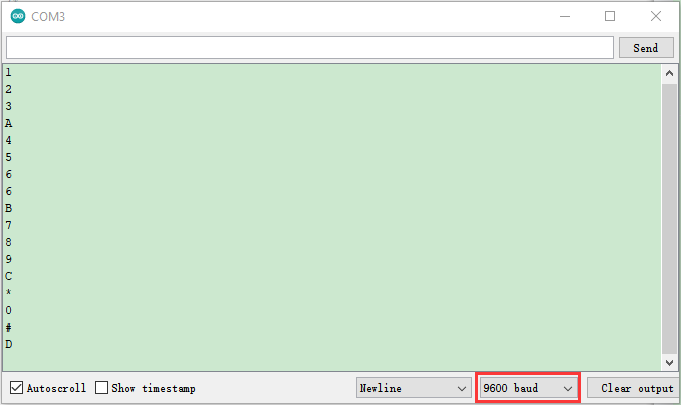

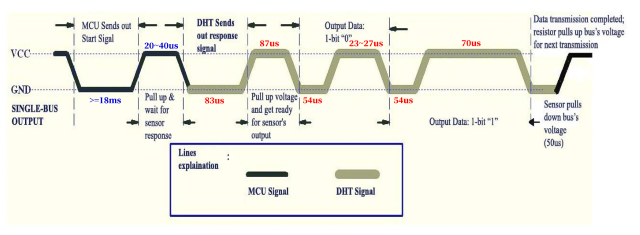

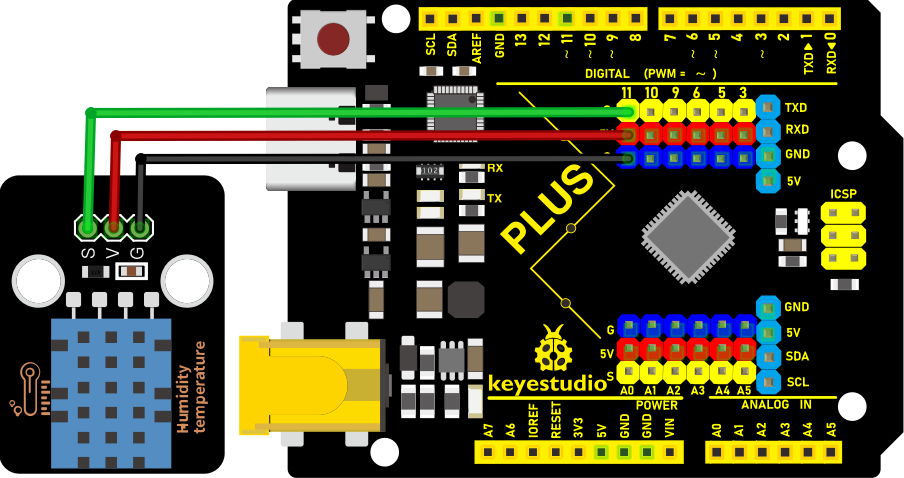

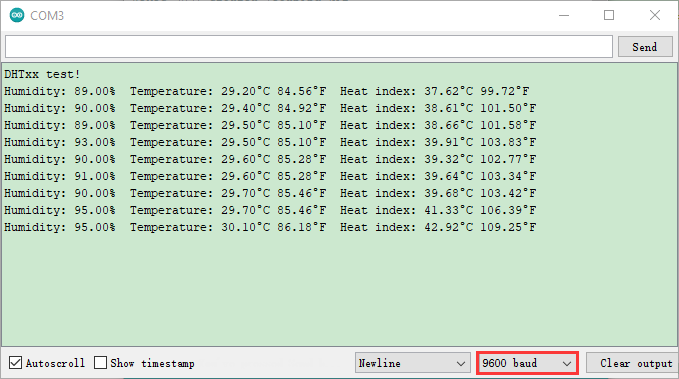

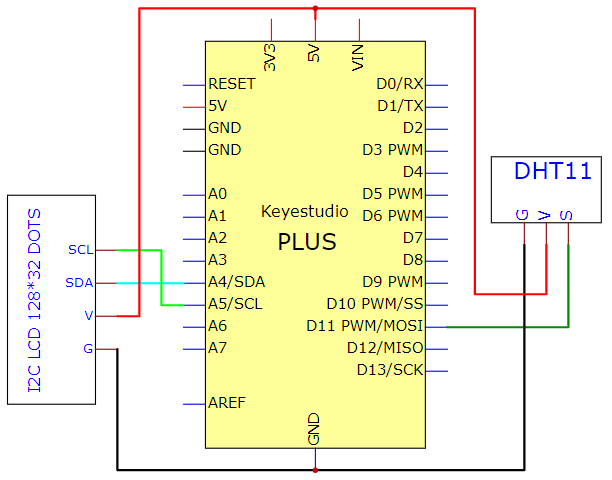

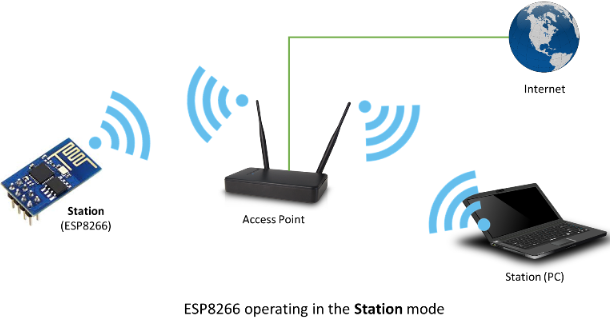

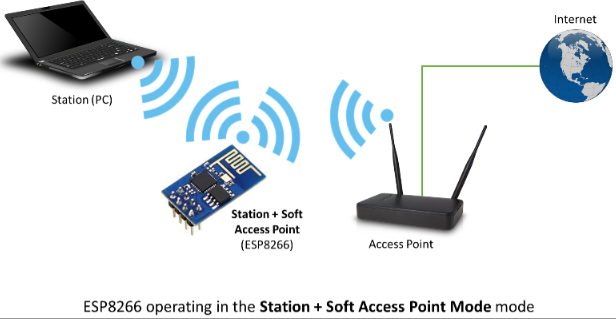

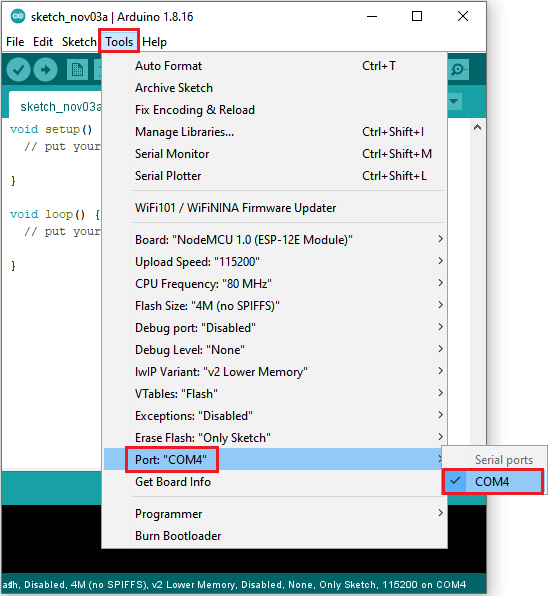

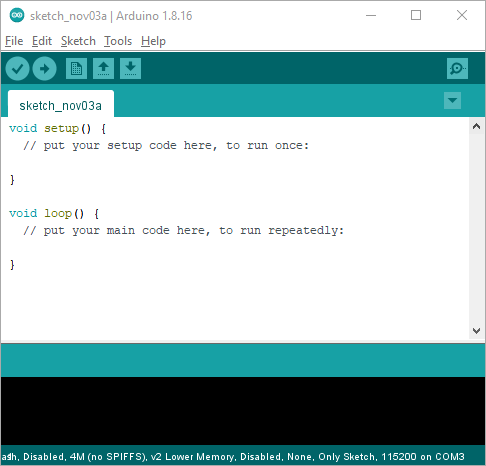

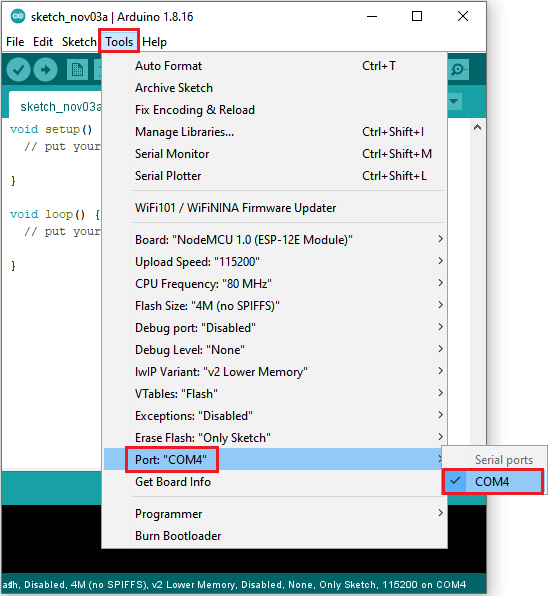

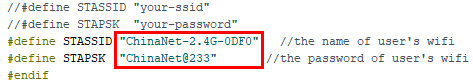

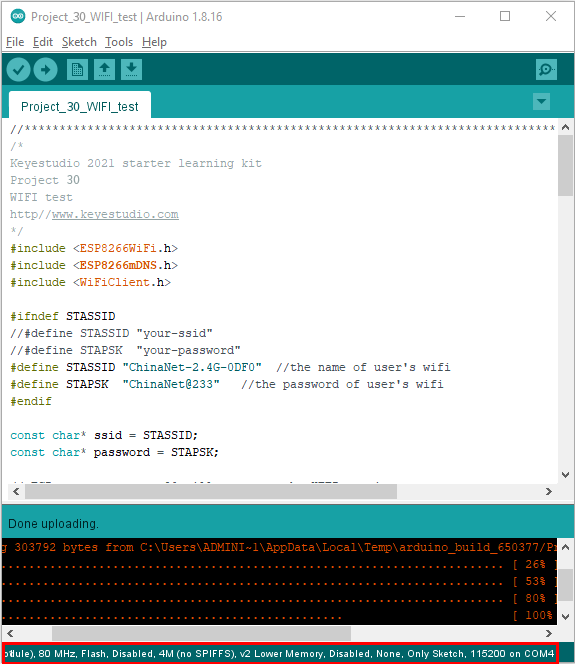

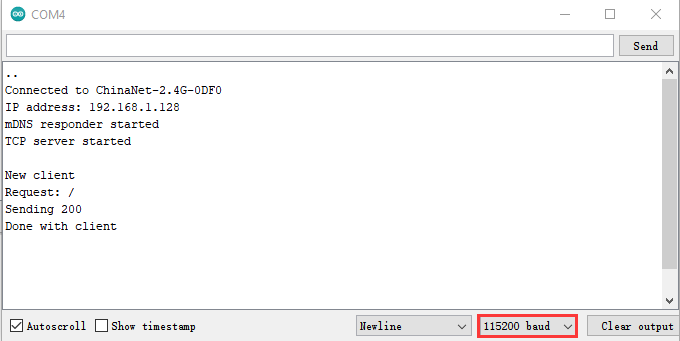

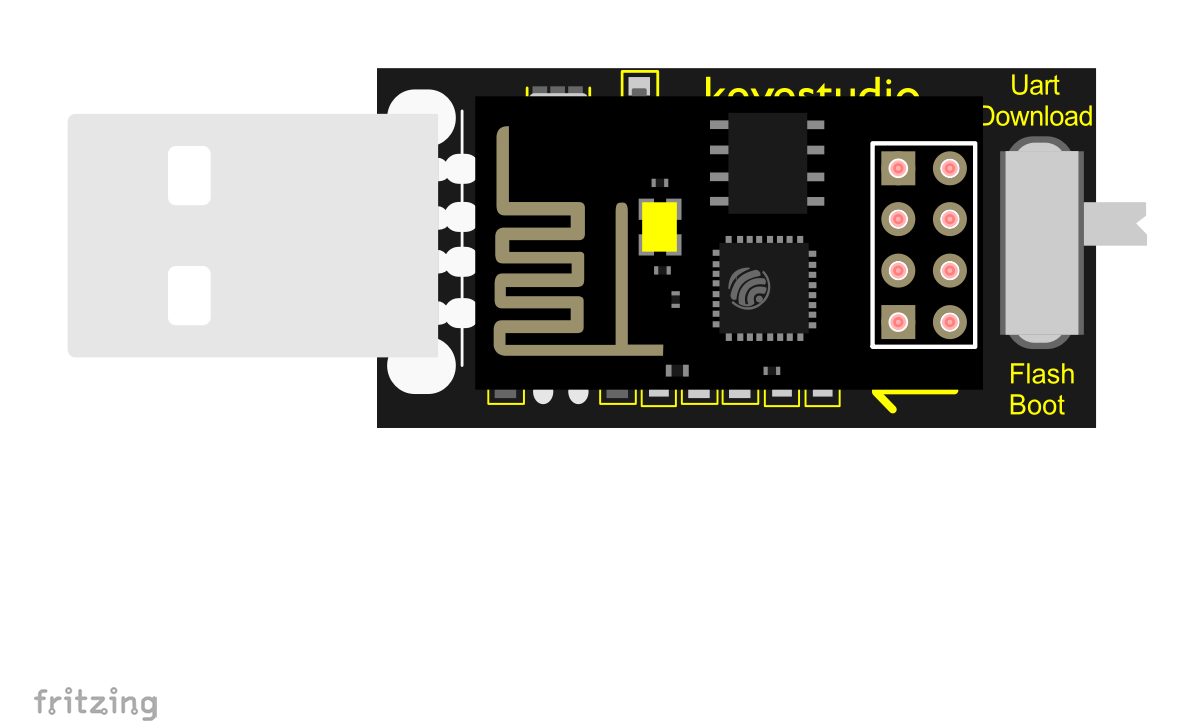

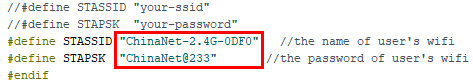

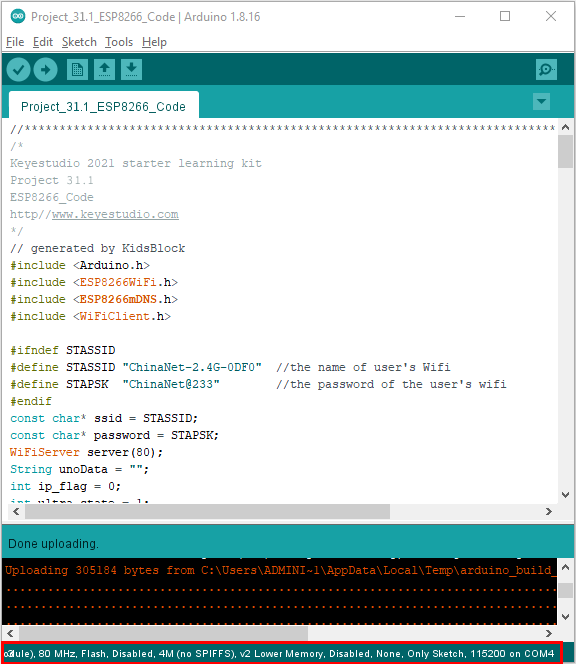

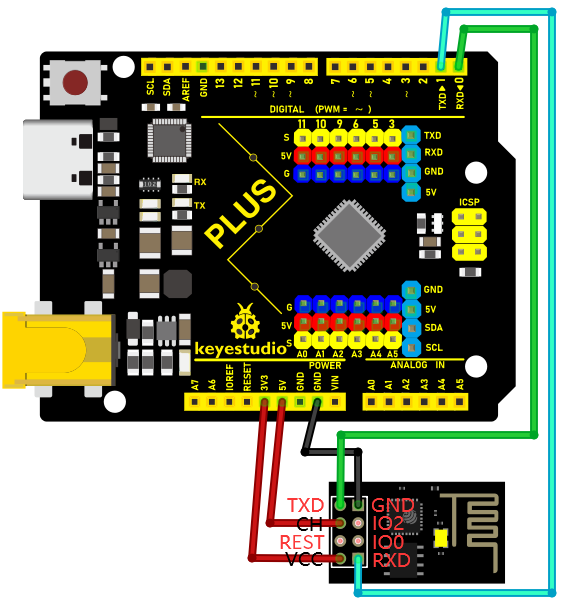

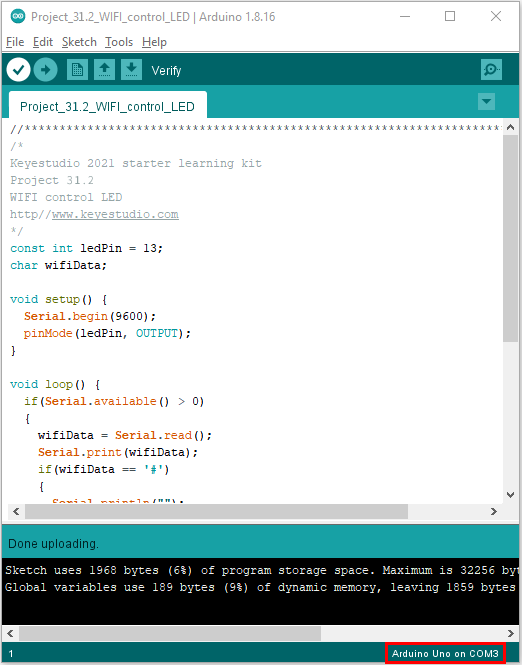

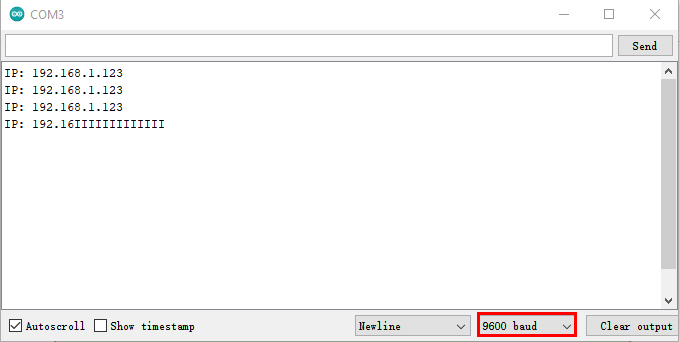

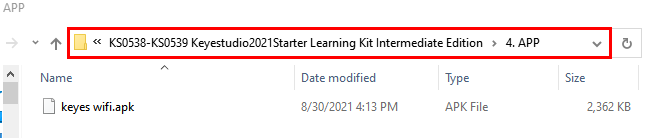

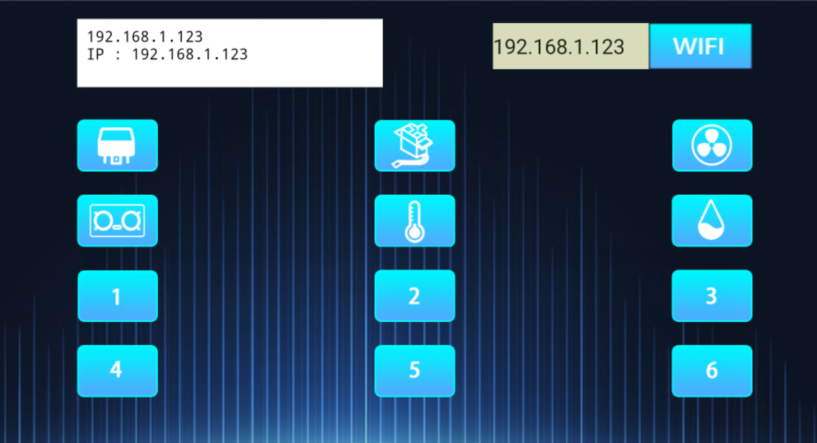

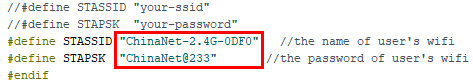

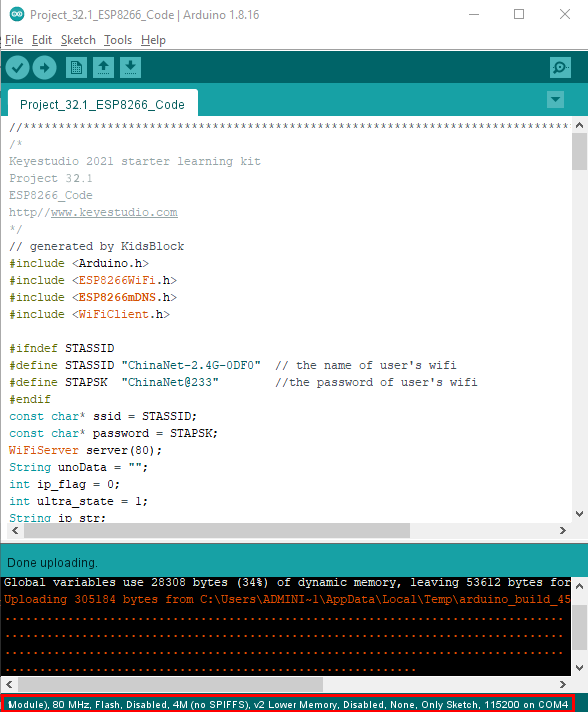

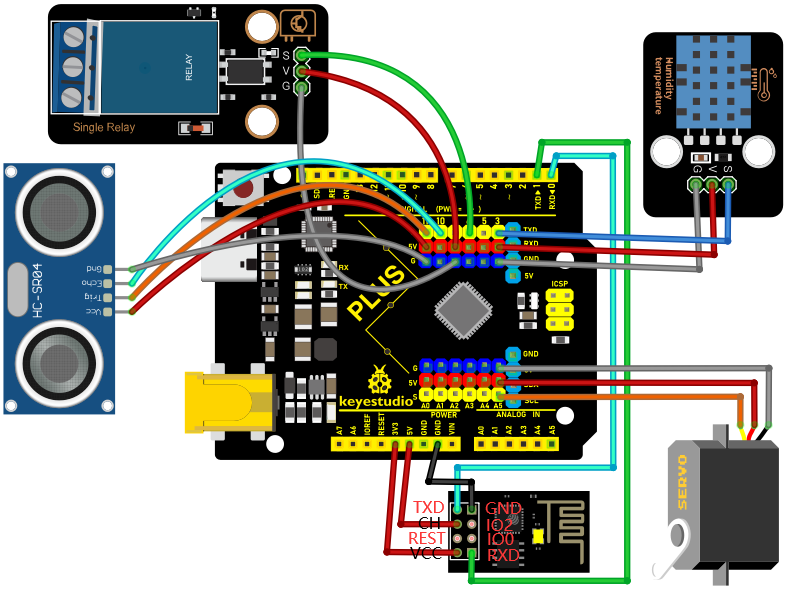

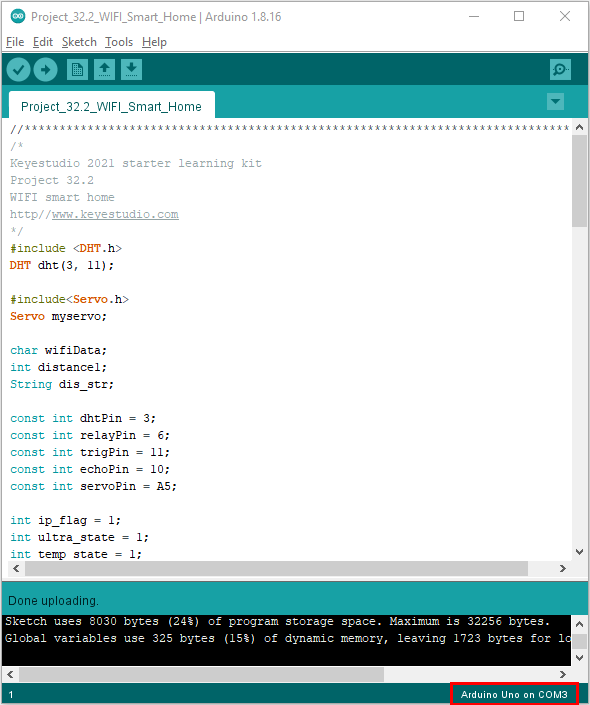

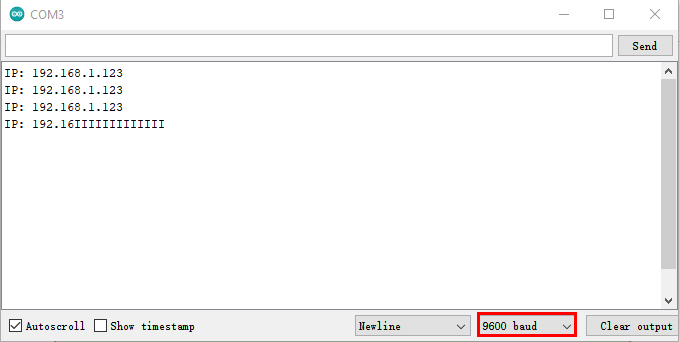

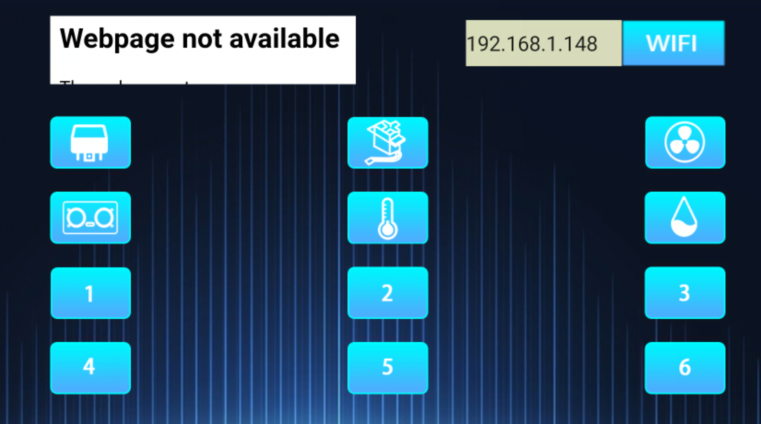

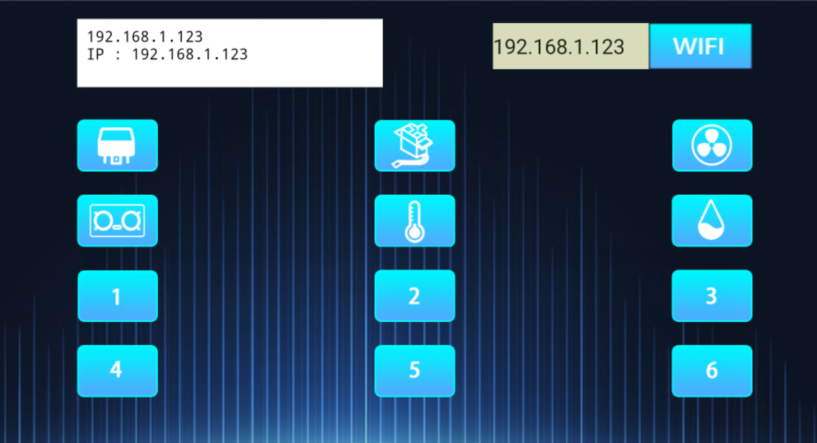

Result